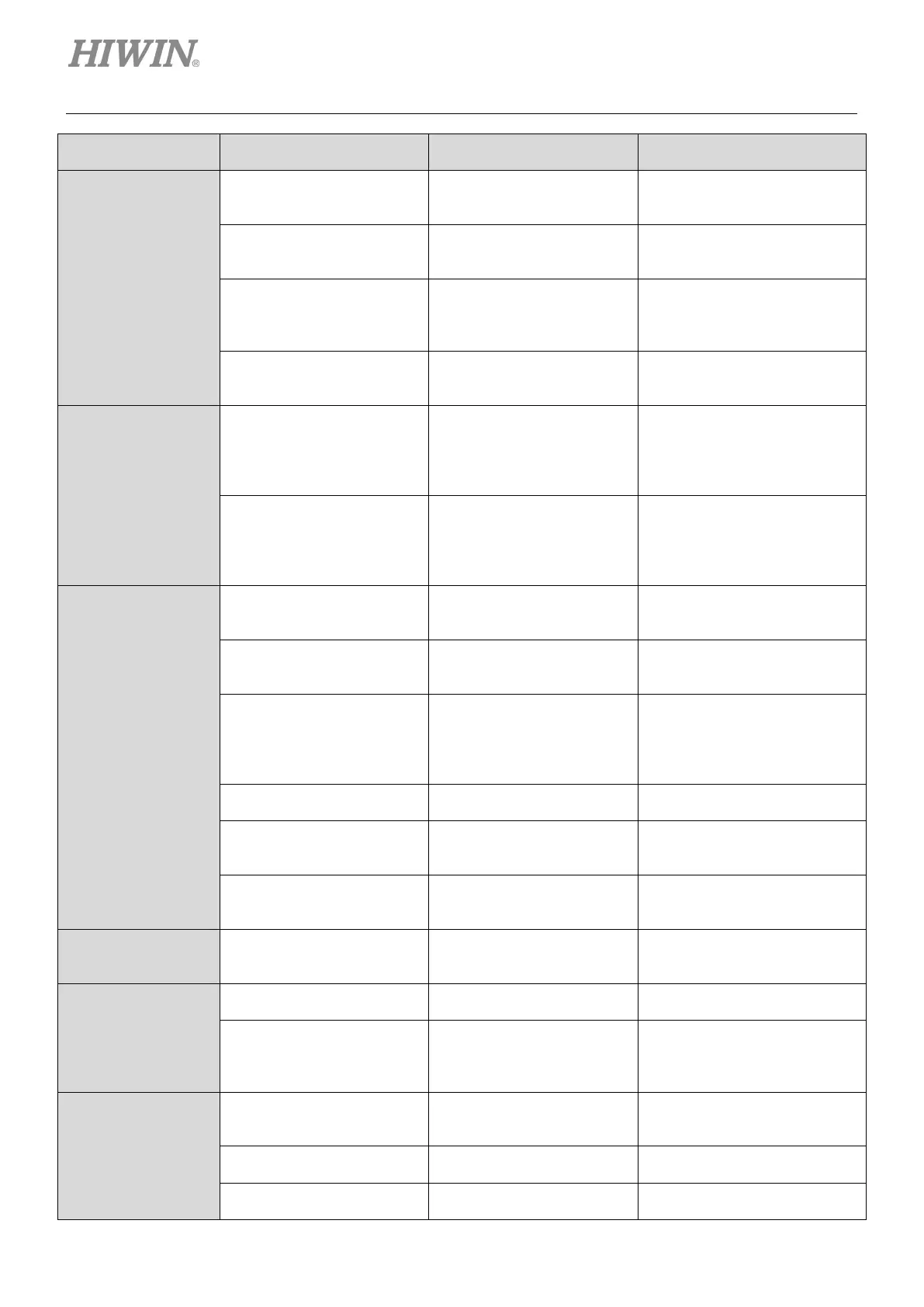

E1 Series Servo Drive User Manual Troubleshooting And Maintenance

13-10 HIWIN MIKROSYSTEM CORP.

Alarm Number And

Alarm Name

Cause Confirmation Method Corrective Action

AL.510

Overspeed

phases in the motor wiring

Check the wiring of the

servo motor.

Check if the wiring is correct.

exceeds the maximum

Check the command value.

Decrease the command value

or adjust the gain.

The motor velocity exceeds

the maximum velocity.

Monitor and check the

waveform of motor velocity.

command input gain and

adjust the servo gain or

Servo drive malfunction N/A

malfunction, please replace

AL.511

Encoder pulse output

overspeed

frequency is too large and

exceeds the output

bandwidth of the servo

Check the output setting of

encoder pulse.

Decrease the setting of

encoder output resolution

(Pt281) or number of encoder

output pulses (Pt212).

frequency exceeds the

output bandwidth of the

servo drive, since the motor

Check the output setting of

encoder pulse and motor

velocity.

Decrease the motor velocity.

AL.710

Overload

(instantaneous

maximum load)

AL.720

Overload

(continuous

maximum load)

The wiring of the motor is

poor or the signal of the

Check the wiring.

Check if the wirings of the

motor and linear encoder are

the overload detection

detection value and motion

Re-calculate and adjust the

load and operating condition.

Overload occurs since the

motor cannot be operated

due to mechanical factor

(such as mechanical

and motor velocity. Check if

the friction of the

mechanism is too large or

Improve the mechanism.

Decrease the load and adjust

the operating condition.

The resolution setting of the

encoder is incorrect.

Check the setting value of

encoder resolution.

Set the encoder resolution to a

proper value.

The phase sequence of the

motor is incorrect.

of motor and the installation

Adjust the setting value of

Pt000 = t.X.

Servo drive malfunction N/A

malfunction, please replace

Power board

The power board

overheats.

N/A

malfunction, please replace

AL.800

Encoder data backup

error

An error occurs in the

encoder backup data.

N/A Initialize the absolute encoder.

Encoder malfunction N/A

Power on again. If the alarm

occurs again, it could be motor

malfunction, please replace

AL.810

Encoder battery

undervoltage

The usage of encoder is not

correctly set.

Check if the encoder you

use is absolute type.

set according to the encoder in

The battery of the absolute

encoder is abnormal.

Check if the battery voltage

is 5 V.

Replace the battery or encoder

cable.

Encoder malfunction N/A

Power on again. If the alarm

occurs again, it could be motor

Loading...

Loading...