ENGINEERING MANUAL OF AUTOMATION CONTROL

ELECTRONIC CONTROL FUNDAMENTALS

124

Another material used in RTD sensors is platinum. It is

linear in response and stable over time. In some applications

a short length of wire is used to provide a nominal resistance

of 100 ohms. However, with a lo w resistance value, the

temper atur e indica tion can be ef fected b y element self hea ting

and sensor lead wire resistance . Additionall y, due to the small

amount of resistance change of the element, additional

amplification m ust be used to incr ease the signal le vel.

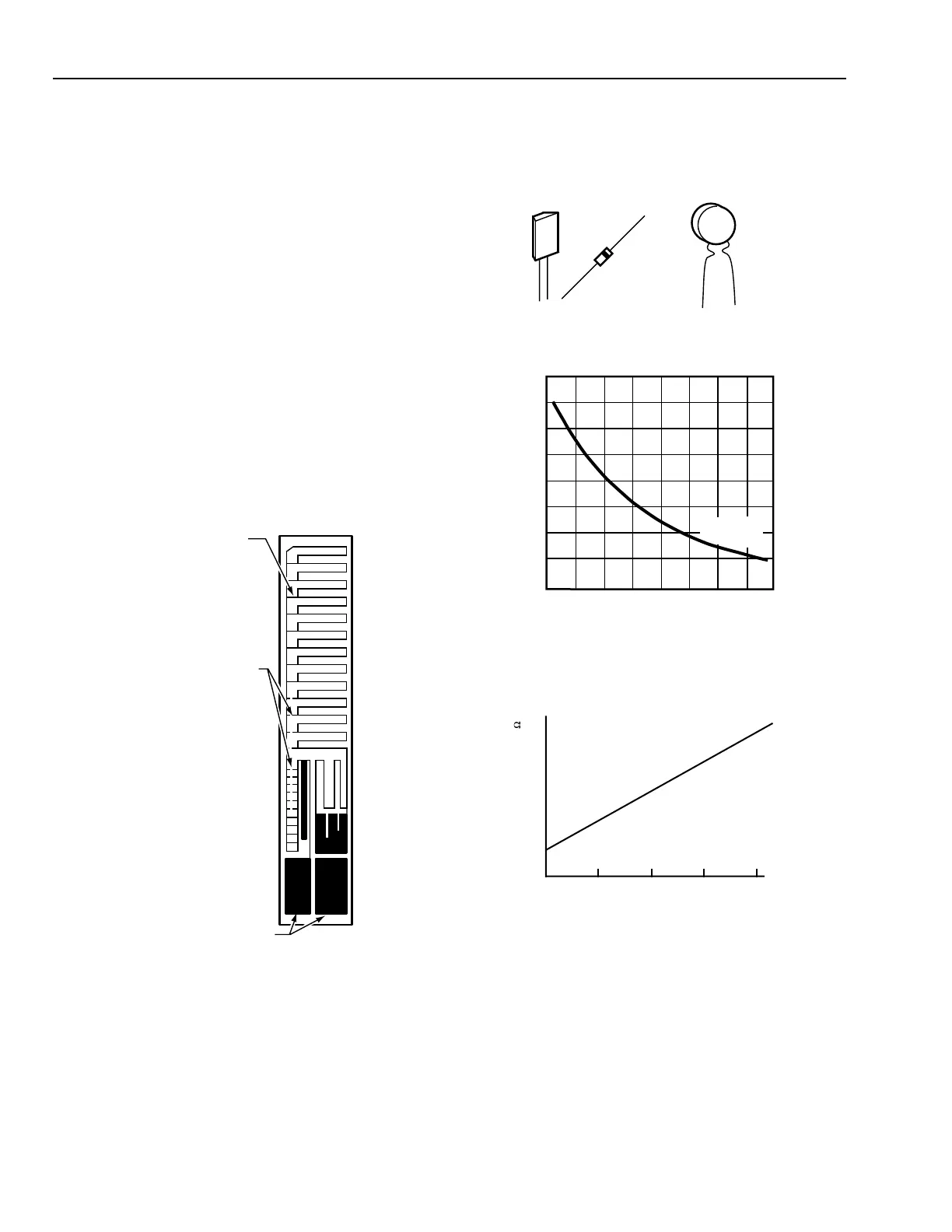

To use the desir able char acter istics of pla tinum and minimiz e

any offset, one man ufactur ing technique de posits a film of

platinum in a lad der pa tter n on an insula ting base . A laser

tr imming method (F ig. 4) then b ur ns away a por tion of the metal

to calibr ate the sensor , pr oviding a r esistance of 1000 ohms a t

74F. This pla tinum film sensor pr ovides a high r esistance-to-

temper atur e relationship. With its high r esistance , the sensor is

relatively immune to self-hea ting and sensor lead wire resistance

offsets. In ad dition, the sensor is an e xtr emely low-mass de vice

and r esponds quic kly to chang es in temper atur e. RTD elements

of this type ar e common. Ear ly thin f ilm pla tinum R TDs dr ifted

due to their high surf ace-to-volume r atio which made them

sensitive to contamina tion. Impr oved packaging and f ilm

isolation ha ve elimina ted these pr oblems r esulting in incr eased

use of pla tinum R TDs over wir e wound and NTC ther mistor s.

LADDER NETWORK OF

METALLIC FILM RESISTOR

LASER TRIM (INDICATEDBY

GAPS IN LADDER NETWORK)

CONNECTION PADS

C3098

Fig. 4. Platinum Element RTD Sensor.

Solid-State Resistance Temperature Devices

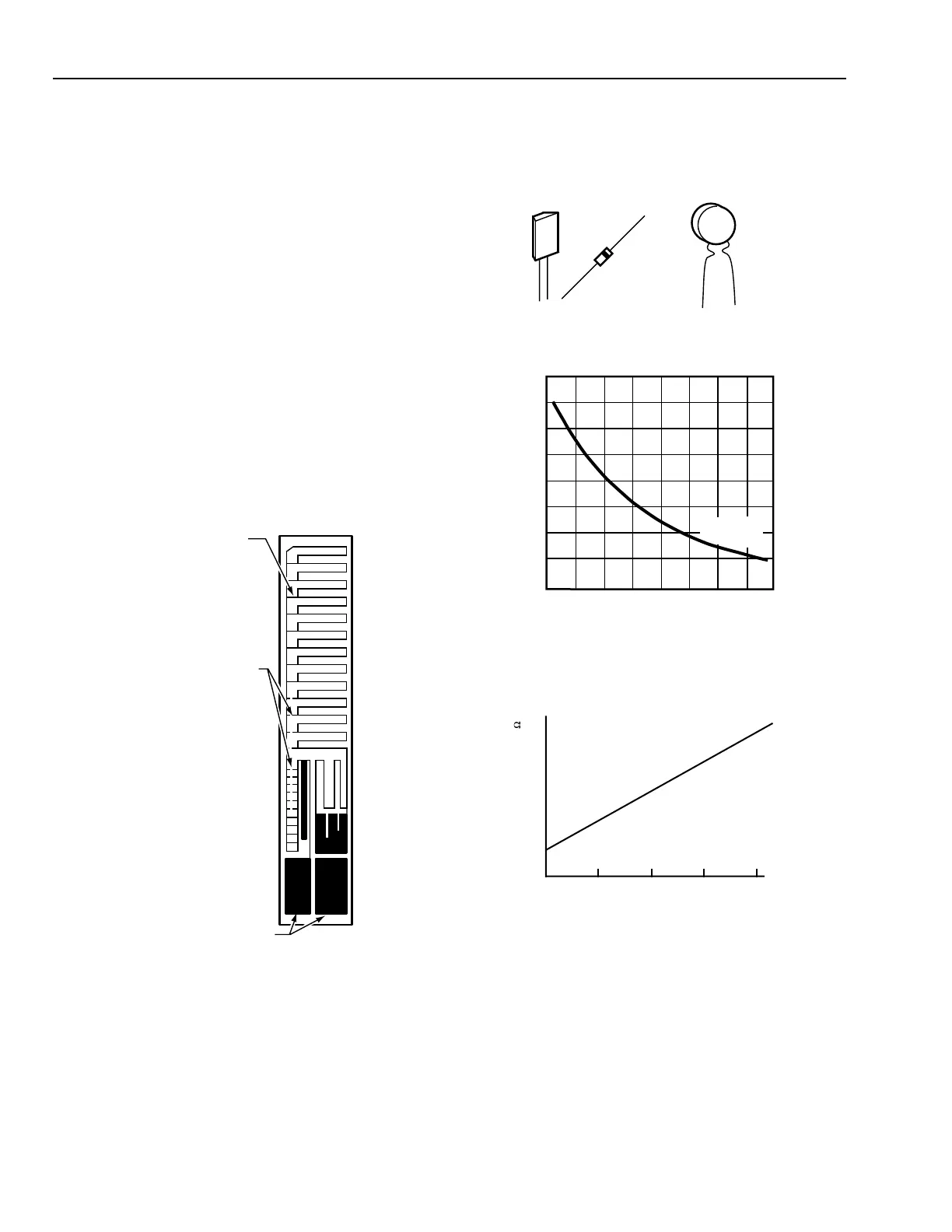

Figur e 5 shows examples of solid-sta te r esistance temper atur e

sensor s having negative and positi ve temper atur e coefficients.

Thermistor s are negative temper atur e coefficient sensor s

typicall y enclosed in very small cases (similar to a glass diode

or small tr ansistor) and pr ovide quick response. As the

temperature increases, the resistance of a thermistor decreases

(Fig. 6). Selection of a thermistor sensor must consider the

highly nonlinear temperature/resistance characteristic.

POSITIVE RTD

THERMISTORS

C3077

Fig. 6. Resistance vs Temperature Relationship

for Solid-State Sensors.

Positive temper atur e coefficient solid-sta te temper atur e

sensors may have relatively high r esistance values a t room

temper atur e. As the temper atur e incr eases, the r esistance of the

sensor incr eases (Fig. 6). Some solid-sta te sensor s have near

perfect linear c har acter istics over their usa ble temper atur e rang e.

TEMPERATURE (DEGREES)

o

F

30

40 50 60 70

80

90

100

110

0

10

20

30

40

RESISTANCE (OHMS)

20K OHM AT

77

o

F (25

o

C)

80K

70K

60K

50K

40K

30K

20K

10K

o

C

TEMPERATURE (°F)

POSITIVE RTD RESISTANCE ( )

050100 200150

M15034

POSITIVE RTD

20K OHM NTC THERMISTOR

Fig. 5. Solid-State Temperature Sensors.

Loading...

Loading...