ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

368

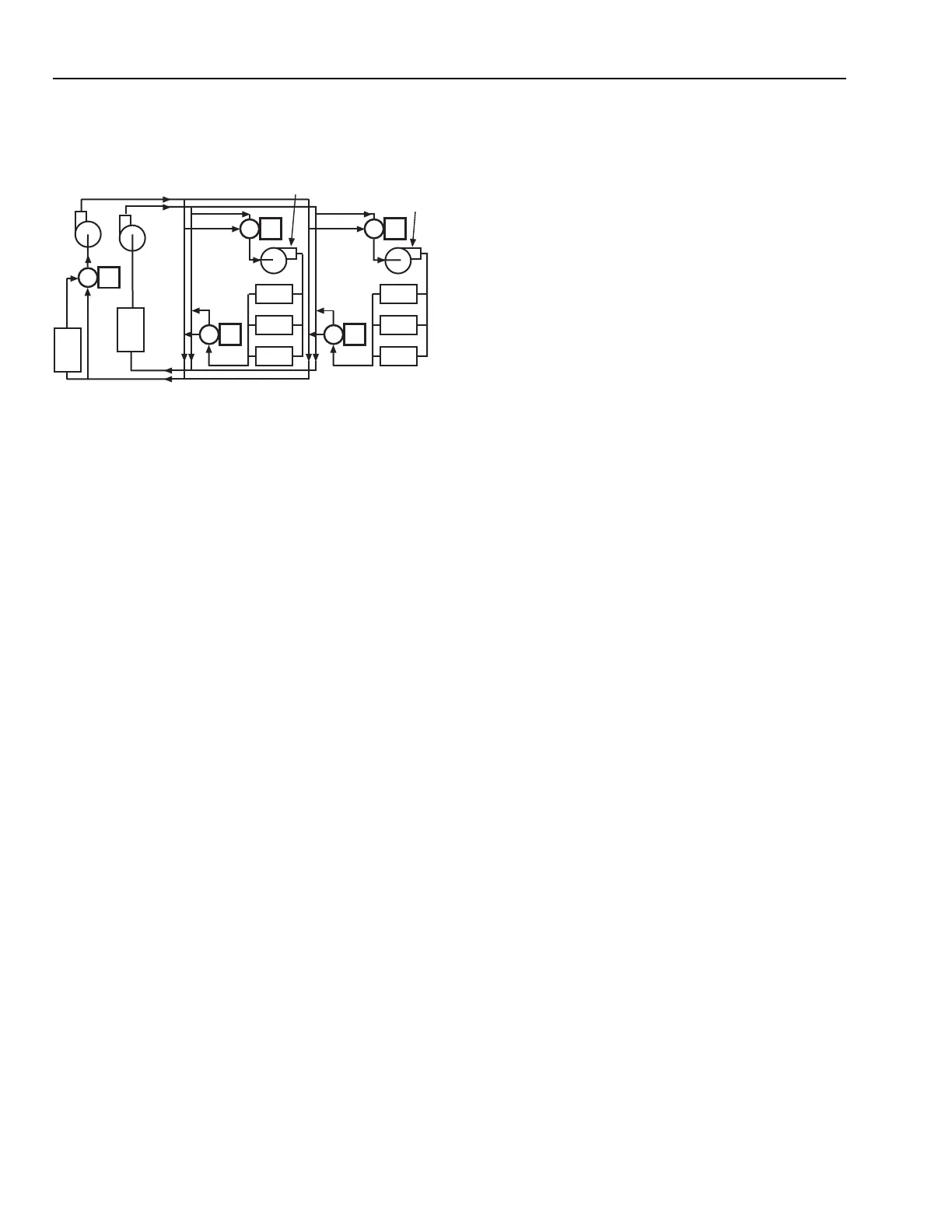

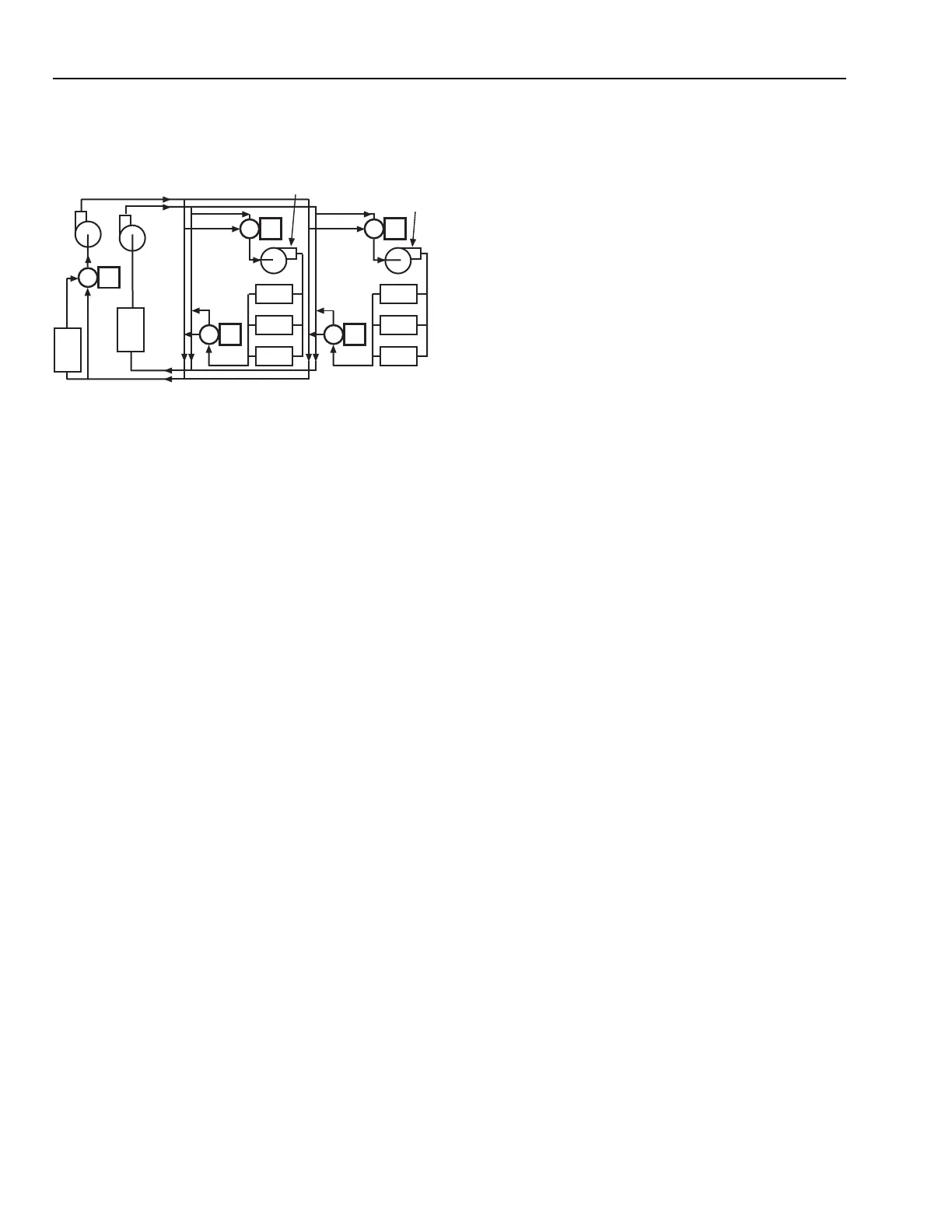

Figure 100 uses three-way valves V1 through V4 operating

two position to accomplish zone changeover. In large systems,

two-way valves may offer a tighter isolation of the hot and

chilled water circuits than three-way valves.

are not considered in this section. Not all of Objectives 1 through

7 may apply to any given distribution system.

1. Steam mains must provide adequate capacity so steam

velocity is between 8,000 and 12,000 feet per minute (133

to 200 feet per second).

2. Water must not be allowed to accumulate in the mains.

Provisions must be made for the use of traps or

superheated steam to reduce or eliminate water in mains.

3. Pockets of water must not be allowed to accumulate.

Steam traveling at 200 feet per second (135 mph) can

propel the water causing water hammer, which can

damage or destroy piping.

4. Condensate must be returned to the boiler at the same

rate as steam leaves the boiler. Otherwise, the boiler will

be shut down by low water cutoff control or be damaged

from lack of water covering heated metal.

5. Provision must be made to expel the air when steam is

again supplied. When any part of the system is not

supplied with steam, that part of the system fills up with

air from the atmosphere. If air is present with the steam,

the air plates the heat exchanger surfaces and reduces

capacity. The oxygen in the air causes pitting of iron and

steel surfaces and the carbon dioxide (CO

2

) in the air

forms an extremely corrosive carbonic acid solution.

6. The return condensate piping system must be sized for a

low-pressure loss to eliminate flashing. For example, if

15 psi steam condenses in a heating coil, the condensate

is still near the boiling point, say 240F; and if the return

main is at atmospheric pressure, the condensate can flash

into steam. This wastes heat and can block the return of

condensate to the boiler.

7. If necessary, the flow of steam must be accurately

measured to account for steam usage. When steam is used

in a closed system (none is vented to atmosphere), the

steam flow to a building or zone can be measured by

measuring condensate flow.

PROPERTIES OF STEAM

One Btu added to one pound of water raises the water

temperature one degree Fahrenheit. When water temperature

reaches 212F at sea level (14.7 psia) it contains 180 Btu/lb (212

– 32) = 180. However, it takes another 970 Btu to convert the

one pound of water to a vapor (steam). The total heat of the

vapor is: 180 Btu/lb + 970 Btu/lb = 1150 Btu per pound. The

970 Btu/lb is the latent heat required to vaporize water.

One pound of water in the liquid state occupies about 28

cubic inches at 32F. When converted to vapor at 212F, it

occupies 27 cubic feet or 1672 times as much space as the liquid.

One pound of steam (water vapor) when cooled and

condensed in a radiator or other heating device gives up 970

Btu to the device and returns to its liquid state. If the liquid

(water) leaves the radiator at 180F, it gives up another 32 Btu,

so the total heating value of low pressure steam is said to be

1000 Btu per pound (actually 32 + 970 or 1002 Btu).

Fig. 100. Two-Pipe Multiple-Zone Dual-Temperature

System Using Zone Pumps.

STEAM DISTRIBUTION SYSTEMS

AND CONTROL

INTRODUCTION

Steam distribution systems are classified as either low

pressure (15 psig and less) or high pressure (above 15 psig).

Low pressure systems have many subclasses such as one-pipe,

two-pipe, gravity, vacuum, and variable vacuum. See HOT

WATER DISTRIBUTION SYSTEMS for steam-to-hot water

converter configurations and control.

ADVANTAGES OF STEAM SYSTEMS VS HOT

WATER SYSTEMS

The principle reasons for the use of steam to distribute heat

in commercial buildings or in groups of buildings separated

from the heating plant are:

—Steam is light weight (27 cubic feet per pound).

—Steam has high heat content (1000 Btu per pound).

—Steam flows through pipes unaided by pumps.

— Steam does not create excessive static pressure on piping

in tall buildings.

—Terminal units can be added or removed without basic

design changes.

—Draining and filling are not necessary to make repairs

as with hot water systems.

—Steam can be distributed through a large system with

little change in heating capacity due to heat loss.

STEAM SYSTEM OBJECTIVES

Carefully consider distribution system objectives when

applying controls either to the boiler or to the distribution system

itself. Control and/or piping of the boiler or steam generator

C2921

V2

PUMP

V4

TERMINAL

UNITS

TERMINAL

UNITS

PUMP

V1

V3

PUMP

CHILLER

BOILER

V5

PUMP

Loading...

Loading...