ENGINEERING MANUAL OF AUTOMATIC CONTROL

BUILDING MANAGEMENT SYSTEM FUNDAMENTALS

194

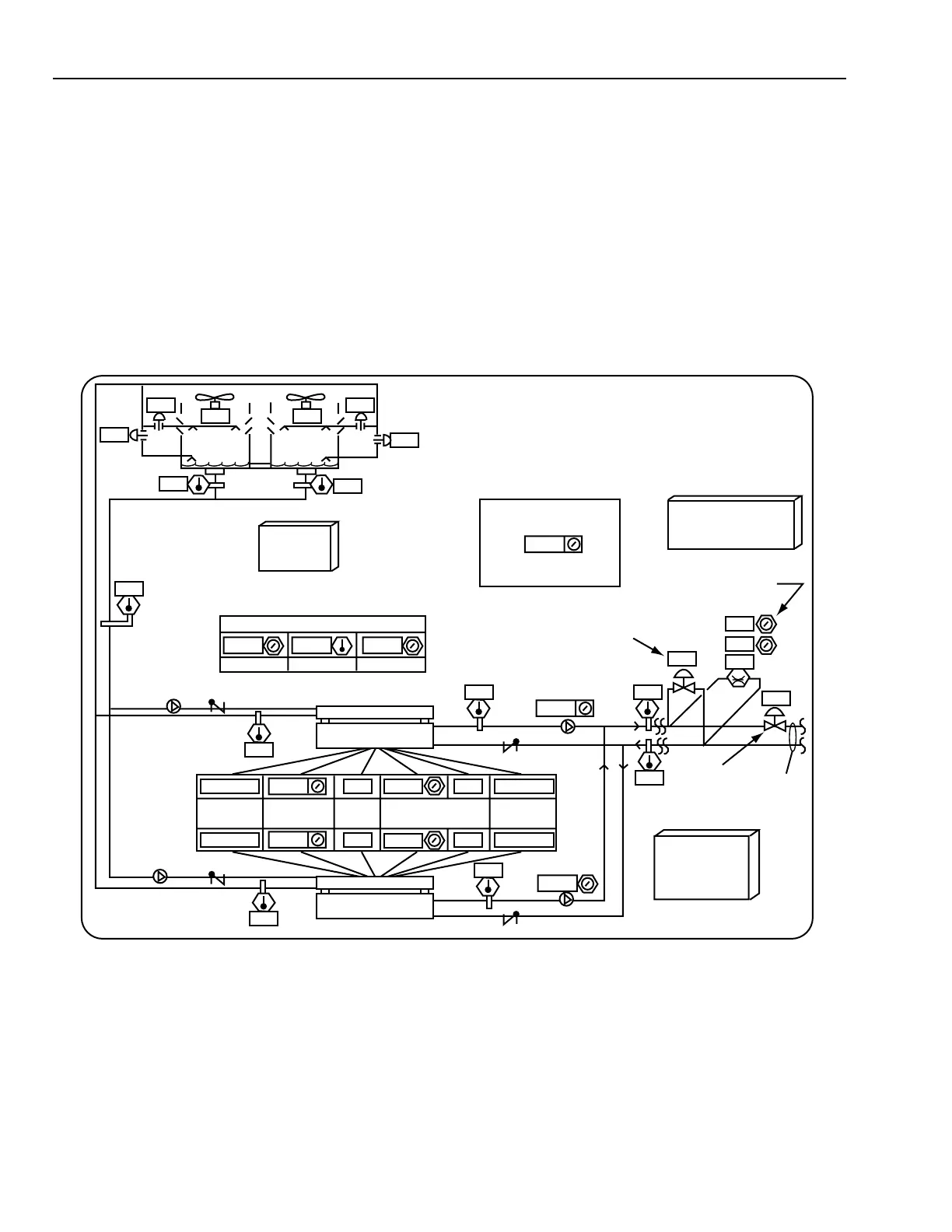

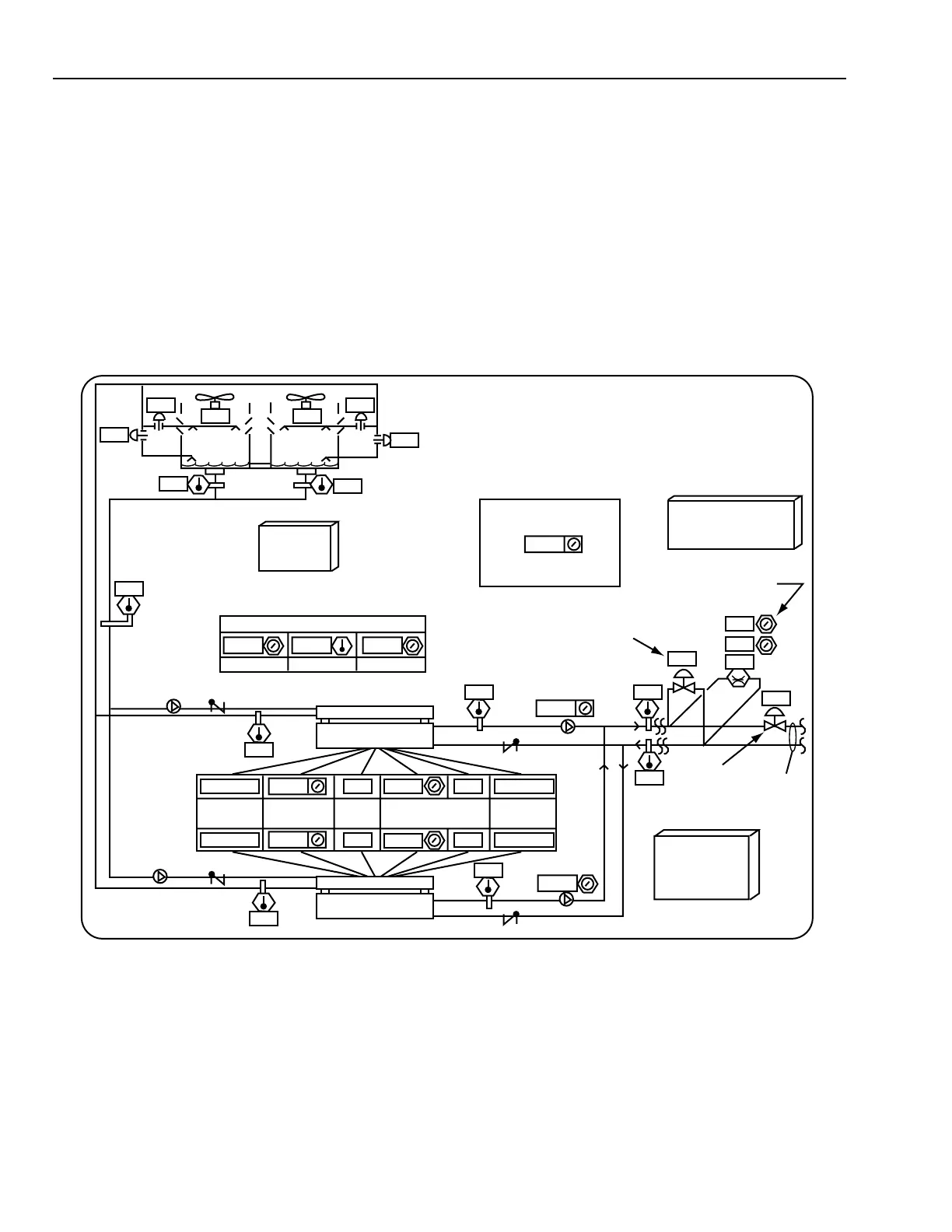

Whereas building control strategies are often established

independent of who will be “operating” the building, operator

graphics should not be. Although the graphic (Fig. 7) presents

an adequate overview of the chiller plant for a building engineer,

it would be overwhelming for custodial or clerical types. They

would not understand the graphic and could cause serious

damage if they issued wrong system commands. Graphic data

compositions must consider the operators ability to understand

and need to know.

Selecting a commandable point presents analog or digital

command options to be executed via dialog boxes, radio buttons,

up-down arrows, etc. Selecting an analog input allows

modification of alarm limit values. Selecting an alarm point

allows entry and modification of the alarm message.

SPECIFYING GRAPHICS (I/O SUMMARIES)

When writing the control sequence of operation, sketch the

graphic (Fig. 7) and note the necessary inputs and outputs

required for control. Develop an Input/Output (I/O) Summary

(Fig. 8) where, the X-axis lists generic types of points and the

Y- axis lists the specific points. Publishing the graphic sketch

with all hardware and software points and symbols is an

excellent alternative to the I/O summary.

Fig. 7. Graphic Sketch for Sequence of Operation.

0

0

100

33

33

100

91

45

00

55.0

78

45.1

55

85

ON

OFF

100

100

78

NORMALENABLED

ENABLED

BY REMOTE

CONTROLS

OPERATING

MODE

ALARM

STATUS

MAX

CURRENT

STATUS

NORMAL

00

AUTO

MINIMUM

CHILLED WATER SETPOINT

MAXIMUMACTUAL

AUTO

1

AUTO

AUTO

45 46 52

100

PRESSURE

CHOKE

VALVE

CHILLER

CONTROL

SETPOINTS/

SEQUENCES

53

TO

AHUs

PSI

PRESSURE

BYPASS

VALVE

DUAL CHILLER

SETPOINT

REDUCTION

LEAD CHILLER

SELECTOR

PRESSURE BYPASS

& CHOKE VALVE

CONTROL

1 = CHILLER 1 LEADS

2 = CHILLER 2 LEADS

COOLING

TOWER

CONTROL

78

DUAL CHILLER PLANT

CONTROL

GRAPHIC DISPLAY

M15004

CHILLER 1

CHILLER 2

%

LOAD

53

78

10.5

Loading...

Loading...