ENGINEERING MANUAL OF AUTOMATION CONTROL

BUILDING AIRFLOW SYSTEM CONTROL APPLICATIONS

273

noise. They work up to a maximum static

pressure of 3 in. wc.

—Vaneaxial fans are basically tubeaxial fans with

straightening vanes added to avoid spiraling air

patterns. They are space efficient, quieter than

tubeaxial fans, and work at static pressures up to

10 in. wc.

FAN PERFORMANCE TERMS

The following are terms used when discussing fan

performance:

Fan volume: The airflow passing through the fan outlet.

Generally this fan outlet value is only slightly less than

the airflow at the fan inlet because specific volume

changes due to air compression are small.

Fan outlet velocity: The fan volume divided by the fan outlet

area. This velocity is a theoretical value because, in

reality, the velocity pattern at the outlet of a fan is not

easy to measure.

Fan Static Pressure (FSP): The fan total pressure minus the

fan velocity pressure (FSP = FTP – FVP). It can be

calculated by subtracting the total pressure at the fan

inlet from the static pressure at the fan outlet.

Fan Total Pressure (FTP): The difference between the total

pressure at the fan inlet and the total pressure at the

fan outlet. The FTP value measures the total

mechanical energy added to the air by the fan.

Fan Velocity Pressure (FVP): The velocity pressure

corresponding to the fan outlet velocity.

FAN LAWS

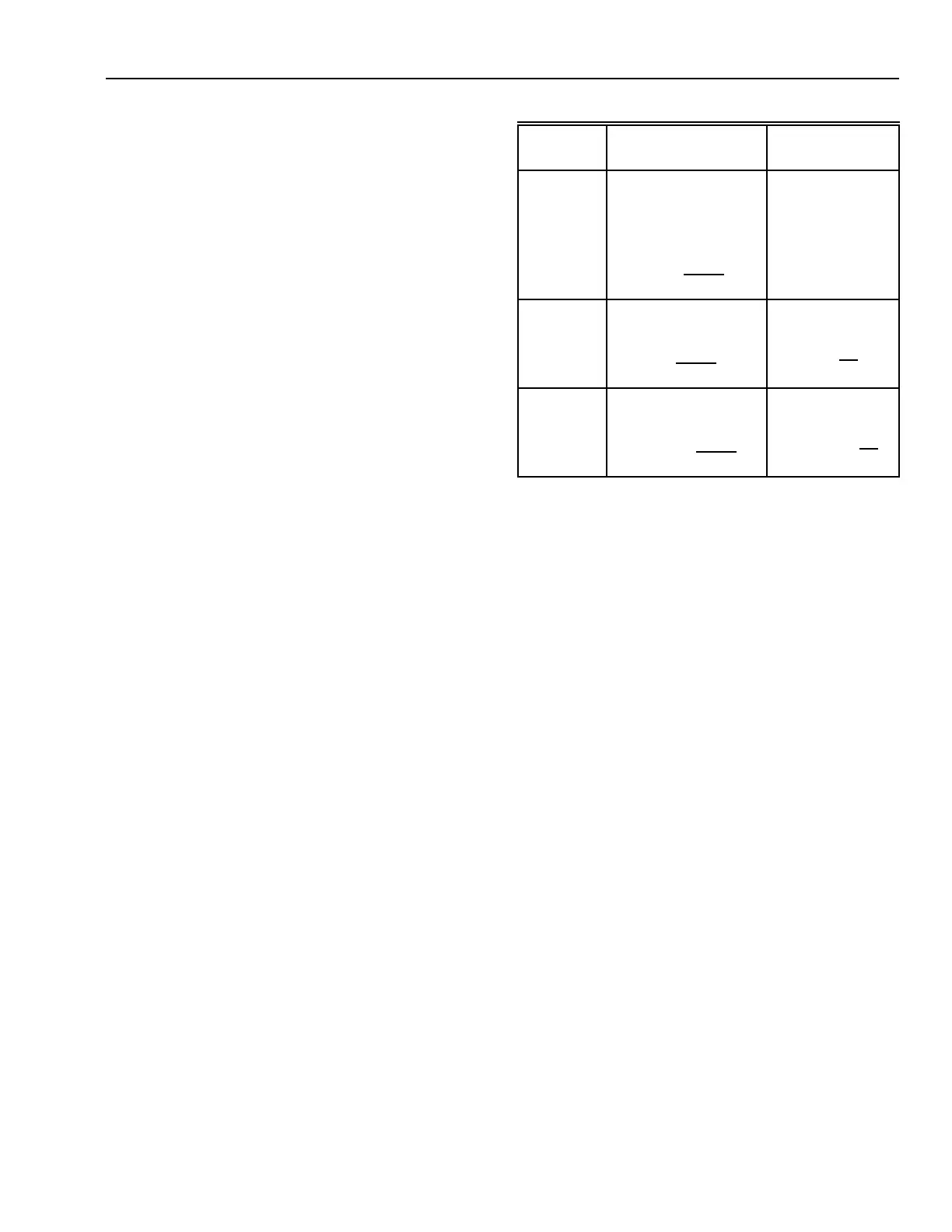

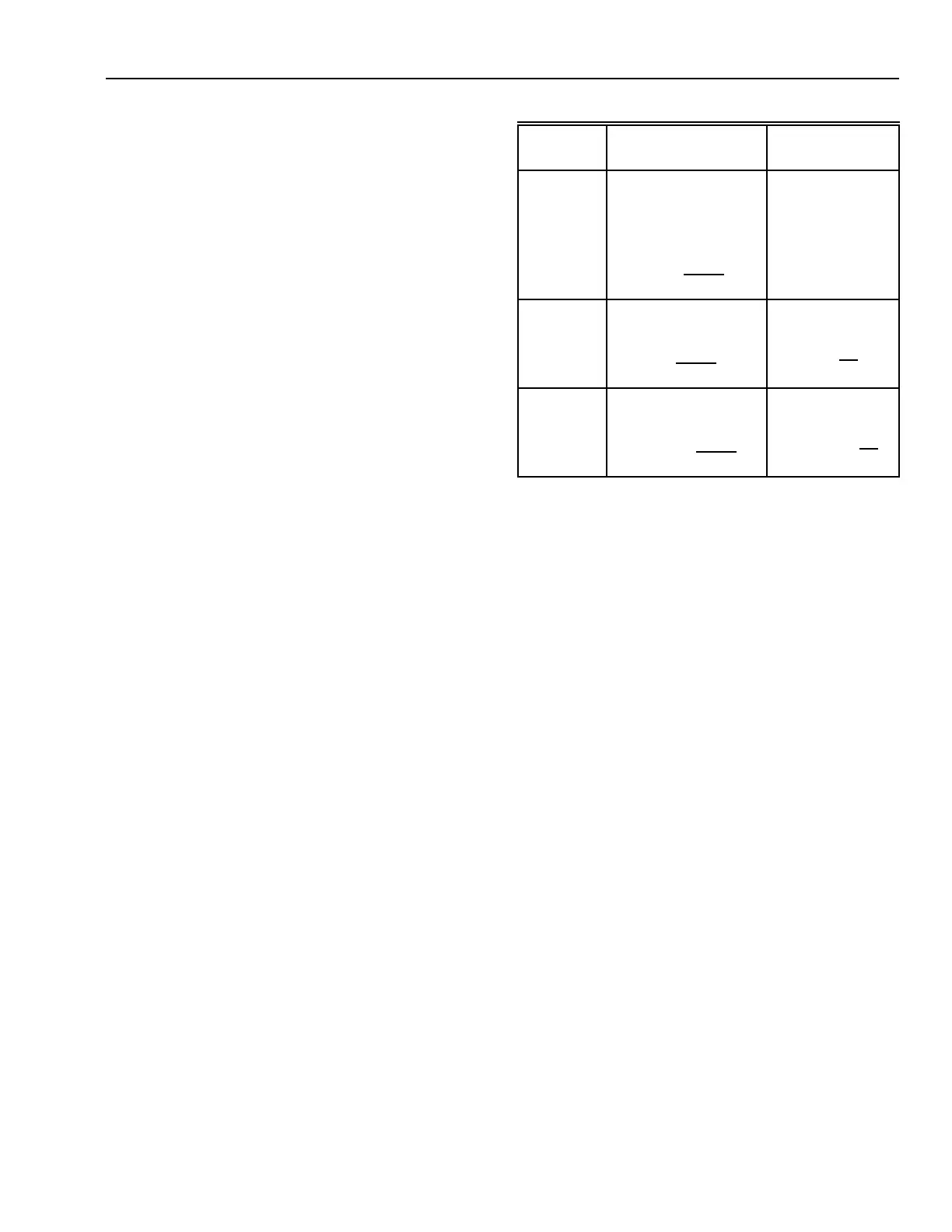

Fan laws (Table 1) are simple and useful when dealing with

changing conditions. Three important laws deal with speed

changes:

1. Airflow varies directly with the fan speed. For example,

doubling the fan speed (rpm) doubles the airflow (cfm)

delivery.

2. Static pressure varies as the square of the fan speed. For

example, doubling the fan speed (rpm) develops four

times the static pressure (in. wc).

3. Power varies as the cube of the fan speed. For example,

doubling the fan speed (rpm) requires eight times the fan

power (hp).

Table 1. Fan Laws

When When

Variable

Speed Changes Density Changes

Varies DIRECT with

Speed Ratio

Does Not Change

Airflow

CFM

2

=

CFM

1

()

RPM

2

RPM

1

2

Varies with SQUARE

of Speed Ratio

Varies DIRECT

with Density Ratio

Pressure

P

2

= P

1

()

RPM

2

RPM

1

2

P

2

= P

1

()

D

2

D

1

Varies with CUBE of

Speed Ratio

Varies DIRECT

with Density Ratio

Horsepower

HP

2

= HP

1

()

RPM

2

RPM

1

3

HP

2

= HP

1

()

D

2

D

1

FAN HORSEPOWER

The theoretical horsepower (hp) required to drive a fan is

the horsepower required if there were no losses in the fan (100

percent efficiency). The horsepower formula is:

Theoretical hp = (cfm x FTP) ÷ 6356

Where:

cfm = Quantity of air

6356 = A constant for English units

FTP = Fan total pressure.

Brake horsepower (bhp) is the actual horsepower required to

drive the fan.

bhp = Theoretical hp ÷ Fan efficiency

=(cfm x FTP) ÷ (6356 x Fan efficiency)

The brake horsepower is always larger than the theoretical

horsepower due to inefficiencies. The actual brake horsepower

of the fan can be determined only by testing.

Loading...

Loading...