SMOKE MANAGEMENT FUNDAMENTALS

178

ENGINEERING MANUAL OF AUTOMATIC CONTROL

The door widths in Table 2 apply only for doors that are

hinged at one side. For other arrangements, door sizes, or for

hardware other than knobs (e.g., panic hardware), refer to

calculation procedures furnished in Design of Smoke Control

Systems for Buildings published by ASHRAE

3

.

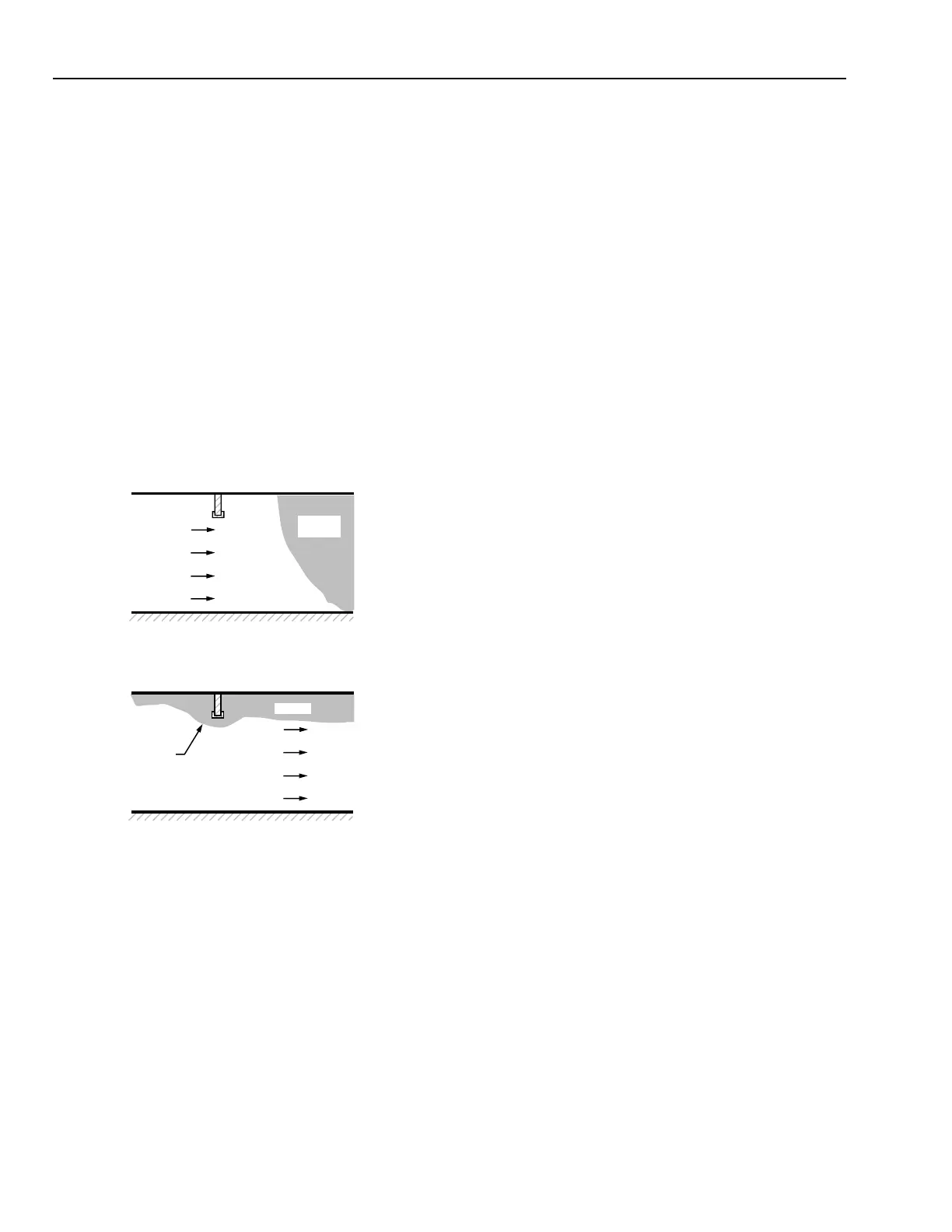

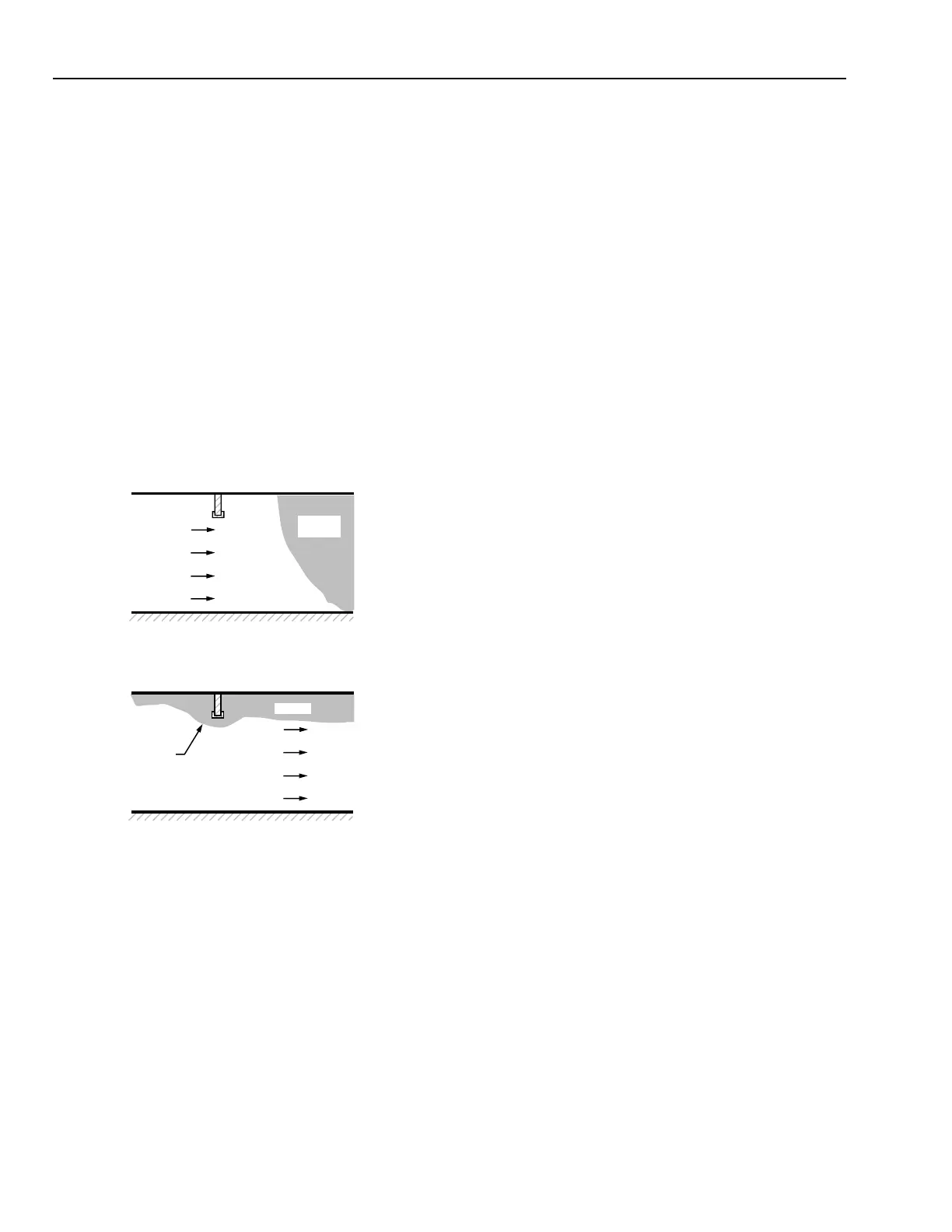

AIRFLOW

Airflow is most commonly used to stop smoke movement

through open doorways and corridors. Figure 4 illustrates a

system with relatively high velocity to prevent backflow of

smoke through an open doorway. Figure 5 illustrates a system

with relatively low velocity which allows backflow of smoke.

The magnitude of the velocity of the airflow required to prevent

backflow depends on the energy release rate of the fire. Since

this can vary, the velocity should be regulated to prevent oxygen

from being fed to the fire. The fact that doors are sometimes

left open during evacuation of a building, allowing smoke to

flow through, should be taken into account in designing the

smoke control system. This is done by designing and testing

the system with one or more doors open.

M13024

DILUTED

SMOKE

RELATIVELY

HIGH AIR

VELOCITY

M13025

SMOKE

RELATIVELY

LOW AIR

VELOCITY

SMOKE

BACKFLOW

Fig. 4. High Air Velocity Preventing Backflow of Smoke

Through an Open Doorway.

Fig. 5. Low Air Velocity Allowing Backflow of Smoke

through an Open Doorway.

PURGING

Because fires produce large quantities of smoke, purging

cannot ensure breathable air in a space while a fire is in progress.

After a fire, purging is necessary to allow firefighters to verify

that the fire is totally extinguished. Traditionally, firefighters

have opened doors and windows to purge an area. Where this

is not possible, the HVAC system can be designed to have a

purge mode.

The principle of dilution can be applied to zones where smoke

has entered and is being purged. Purging dilutes the

contaminated air and can continue until the level of obscuration

is reduced and the space is reasonably safe to enter. The

following equation allows determining a concentration of

contaminant in a compartment after purging for a given length

of time:

3

C=C

0

x e

–at

Where:

C=concentration of contaminant at time, t

C

0

=initial concentration of contaminant

a=purging rate in number of air changes per

minute

t=time after doors close in minutes

e=constant, approximately 2.718

Care must be taken in the use of this equation because of the

nonuniformity of the smoke. Buoyancy is likely to cause greater

concentration of smoke near the ceiling. Therefore,

consideration of the locations of supply and exhaust registers

is important to effective purging.

CONTROL APPLICATIONS

Figure 6 illustrates a smoke control system with detectors,

an initiating panel, and a communications bus to an alarm

processor and remote control panels in appropriate areas of the

building. A configuration similar to this will meet the

requirements of UL 864, Standard for Control Units for Fire-

Protective Signalling Systems, and comply with NFPA 92A

recommended practice for smoke control systems. The remote

control panels position dampers and operate fans to contain or

exhaust smoke, depending on the requirements of the various

areas in the building. The system can have an operator’s control

console for the building personnel and an FSCS from which to

view the status of and override the smoke control system. The

system requires a means of verifying operation, such as

differential pressure or airflow proving devices, for each control

sequence. An uninterruptible power supply (UPS) is optional

but recommended.

Loading...

Loading...