ENGINEERING MANUAL OF AUTOMATIC CONTROL

CONTROL FUNDAMENTALS

28

The difference between repeatability and static error is that

repeatability is the ability to return to a specific condition,

whereas static error is a constant deviation from that condition.

Static error (e.g., sensor error) does not interfere with the ability

to control, but requires that the control point be shifted to

compensate and maintain a desired value.

The dead zone is a range through which the controlled

variable changes without the controller initiating a correction.

The dead zone effect creates an offset or a delay in providing

the initial signal to the controller. The more slowly the variable

changes, the more critical the dead zone becomes.

CAPACITANCE

Capacitance differs from capacity. Capacity is determined

by the energy output the system is capable of producing;

capacitance relates to the mass of the system. For example,

for a given heat input, it takes longer to raise the temperature

of a cubic foot of water one degree than a cubic foot of air.

When the heat source is removed, the air cools off more

quickly than the water. Thus the capacitance of the water is

much greater than the capacitance of air.

A capacitance that is large relative to the control agent tends

to keep the controlled variable constant despite load changes.

However, the large capacitance makes changing the variable

to a new value more difficult. Although a large capacitance

generally improves control, it introduces lag between the time

a change is made in the control agent and the time the controlled

variable reflects the change.

Figure 44 shows heat applied to a storage tank containing a

large volume of liquid. The process in Figure 44 has a large

thermal capacitance. The mass of the liquid in the tank exerts

a stabilizing effect and does not immediately react to changes

such as variations in the rate of the flow of steam or liquid,

minor variations in the heat input, and sudden changes in the

ambient temperature.

LIQUID IN

HEATING

MEDIUM IN

LIQUID OUT

HEATING

MEDIUM OUT

C2076

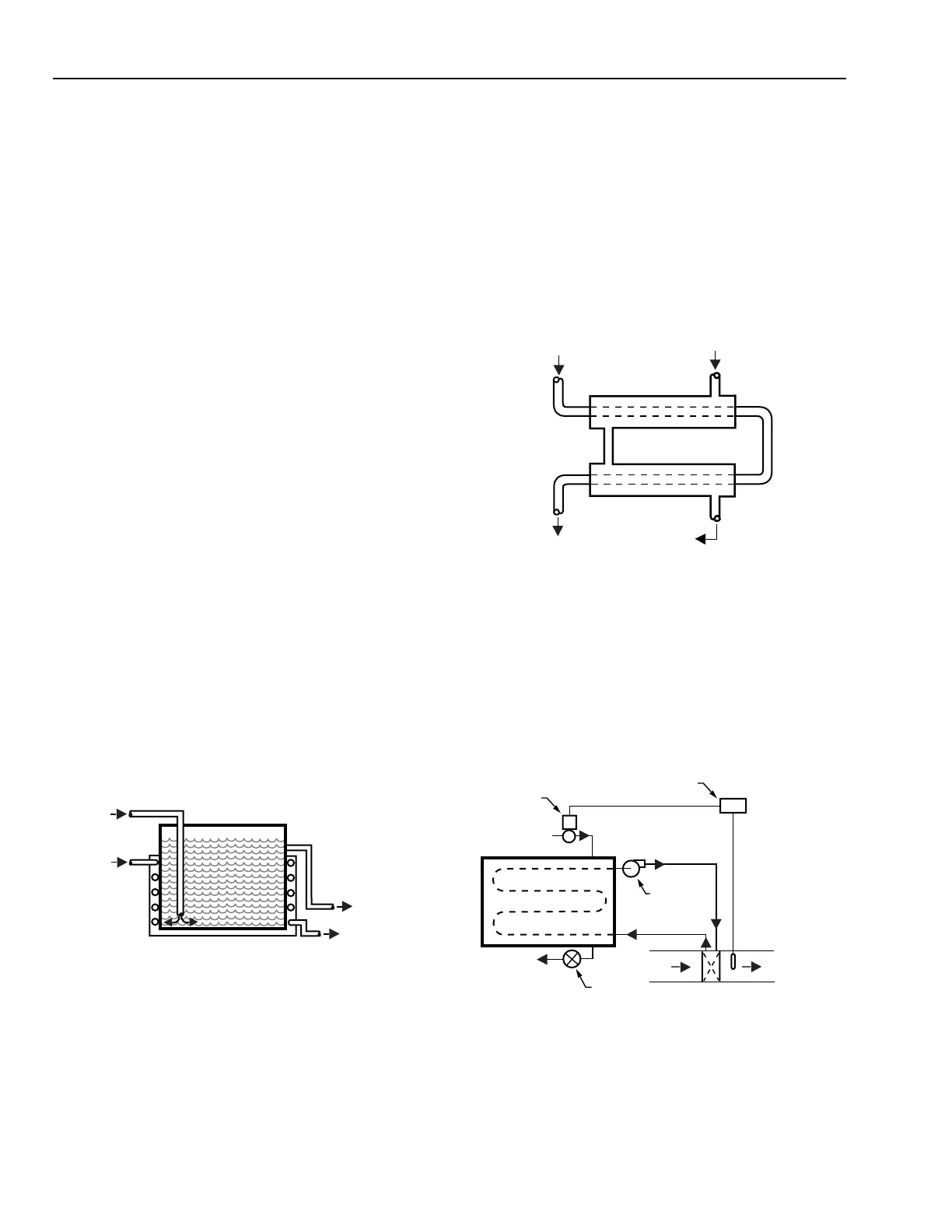

Figure 45 shows a high-velocity heat exchanger, which

represents a process with a small thermal capacitance. The

rate of flow for the liquid in Figure 45 is the same as for the

liquid in Figure 44. However, in Figure 45 the volume and

mass of the liquid in the tube at any one time is small compared

to the tank shown in Figure 44. In addition, the total volume

of liquid in the exchanger at any time is small compared to the

rate of flow, the heat transfer area, and the heat supply. Slight

variations in the rate of feed or rate of heat supply show up

immediately as fluctuations in the temperature of the liquid

leaving the exchanger. Consequently, the process in Figure 45

does not have a stabilizing influence but can respond quickly

to load changes.

Fig. 45. Typical Process with Small Thermal

Capacitance.

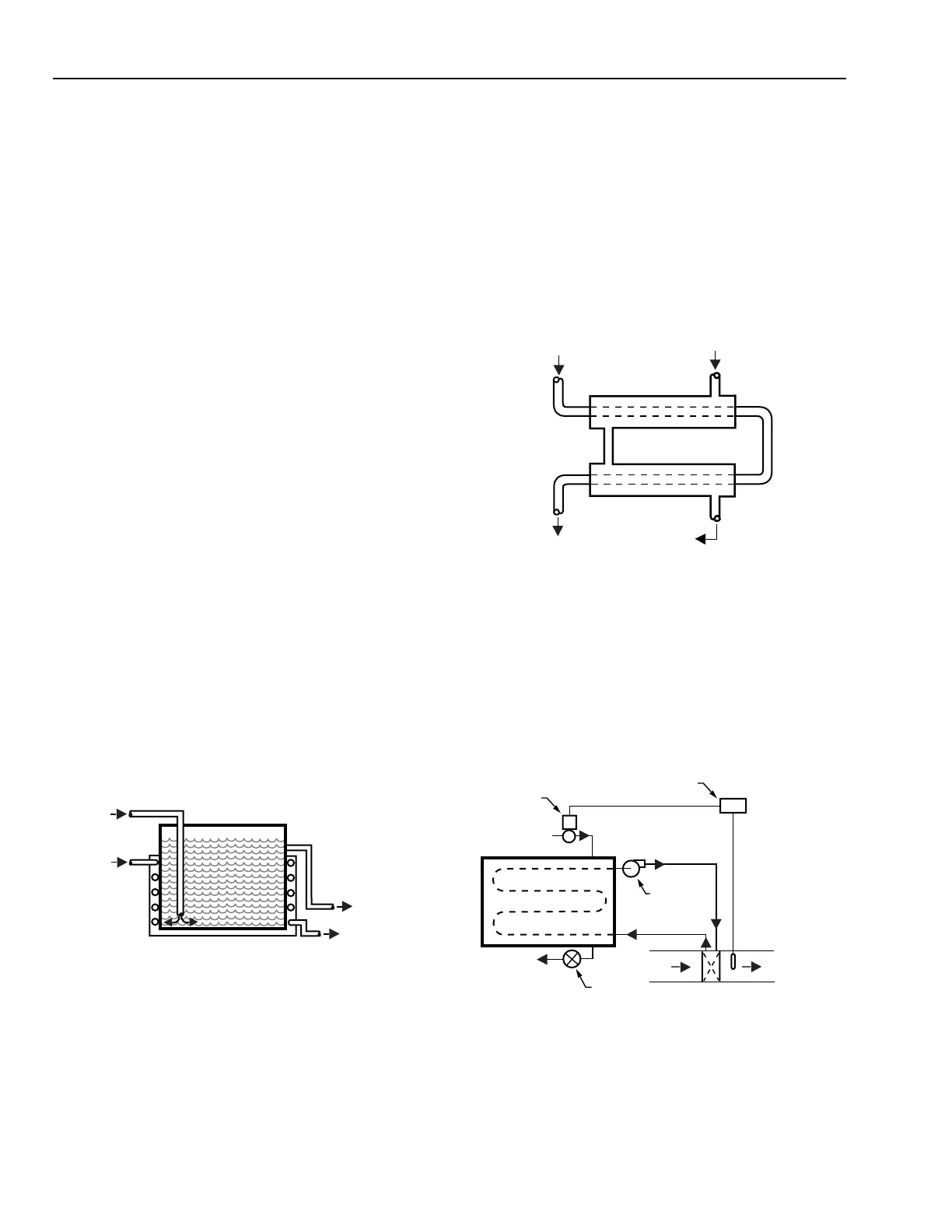

Figure 46 shows supply capacitance in a steam-to-water

converter. When the load on the system (in Figure 44, cold

air) increases, air leaving the heating coil is cooler. The

controller senses the drop in temperature and calls for more

steam to the converter. If the water side of the converter is

large, it takes longer for the temperature of the supply water to

rise than if the converter is small because a load change in a

process with a large supply capacitance requires more time to

change the variable to a new value.

LIQUID

IN

STEAM

IN

TANK

LIQUID

OUT

CONDENSATE

RETURN

C2075

Fig. 44. Typical Process with Large Thermal

Capacitance.

CONVERTER

STEAM

VALVE

CONTROLLER

HOT WATER SUPPLY

(CONSTANT FLOW,

VARYING

TEMPERATURE)

HOT WATER

RETURN

COLD AIR

(LOAD)

CONDENSATE

RETURN

STEAM

TRAP

HEATING

COIL

HOT AIR

(CONTROLLED

VARIABLE)

PUMP

C2077

Fig. 46. Supply Capacitance (Heating Application).

Loading...

Loading...