ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

316

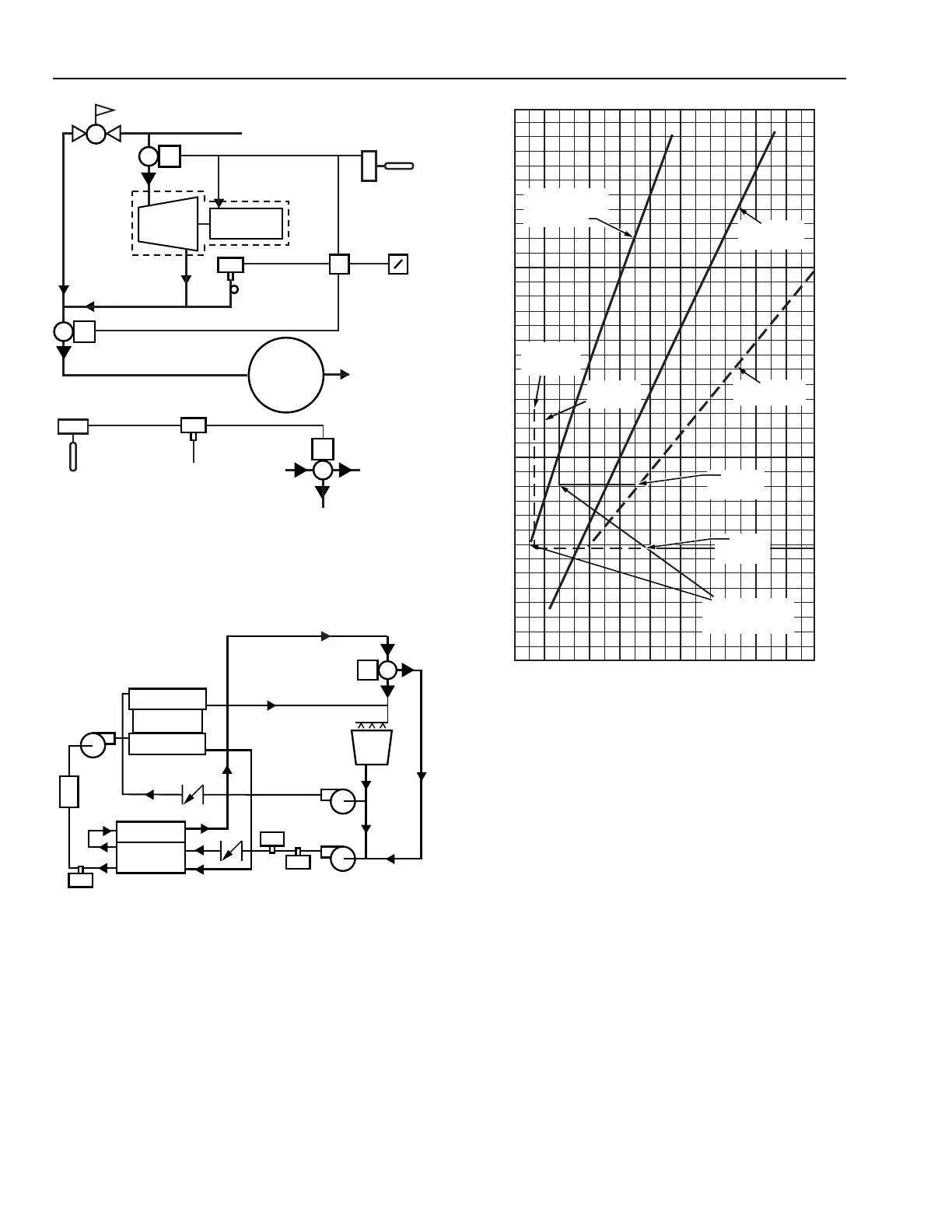

Fig. 21. Schematic of Combination Absorption/

Centrifugal Chiller System Steam Piping

and Control Circuit.

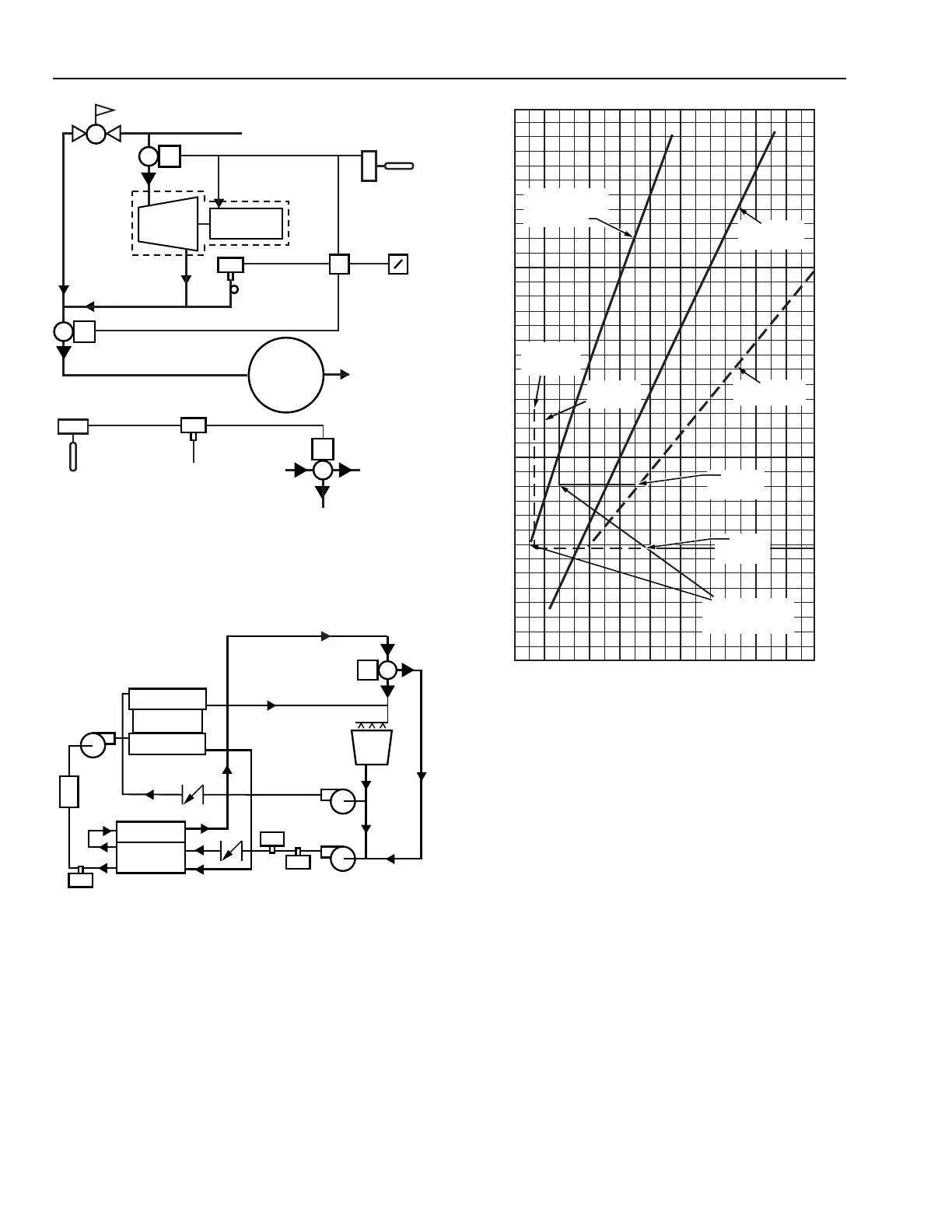

Fig. 23. Typical Steam Consumption, Individual

and Combination Chillers.

CHILLER PUMP OPTIMIZATION

Pump configuration (variable water flow versus constant

water flow) also affects chiller system efficiency. Constant water

flow causes the largest change in efficiency from system no

load to design because the pump energy becomes a greater

percentage of the total energy input at light load conditions.

Va riable water flow, using two-way load valves or variable speed

pumps, maintains the pump load at nearly a constant percentage

of the total energy input at all loads. If a chiller system has

constant water flow, chiller optimization must include pump

energy usage as part of the power calculation to account for

energy cost variations over the range of loads. In a chiller system

using variable water flow, it is not necessary to account for

pump energy cost. Refer to HOT AND CHILLED WATER

DISTRIBUTION SYSTEMS AND CONTROL.

Fig. 22. Schematic of Combination Absorption/

Centrifugal Chiller System Water Piping.

Figure 23 compares the steam consumption of individual

chillers to a combination system showing the savings using the

combination system. The range of centrifugal cutout points

indicates where most centrifugal chillers are shut down and the

absorption chiller provides all cooling required by the system.

CONDENSER

COMPRESSOR

EVAPORATOR

CONDENSER

CHILLER 1

LOAD

C2689

ABSORBER

EVAPORATOR

ABSORPTION

CHILLER

CENTRIFUGAL

CHILLER

COOLING

TOWER

COOLING TOWER

BYPASS VALVE

P2

T2

V2

T1

REFRIGERATION (TONS)

0

100

200

300

400

500

600

700

800

900

1000

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

C1047

TURBINE-DRIVEN

CENTRIFUGAL

CHILLER

15%

CENTRIFUGAL

CAPACITY

25%

CENTRIFUGAL

CAPACITY

RANGE OF

CENTRIFUGAL

CUTOUT

18%

SYSTEM

LOAD

33%

SYSTEM

LOAD

COMBINATION

SYSTEM

ABSORPTION

CHILLER

STEAM CONSUMPTION (1000 LB/HR)

BACK

PRESSURE

TURBINE

COMPRESSOR

TO INLET VANE

ACTUATOR

T1

T2

SENSOR IN

CHILLED

WATER

SUPPLY

RELAY

PRESSURE

CONTROLLER

P1

PRESSURE

CONTROLLER

P2

ABSORPTION/

COMBINATION

SELECTOR

SWITCH

HIGH PRESSURE

STEAM SUPPLY

PRV SET

APPROX.

10 PSI

CENTRIFUGAL

CHILLER

ABSORPTION CHILLER

CAPACITY CONTROL VALVE

ABSORPTION

CHILLER

GENERATOR

CONDENSATE

RETURN

SENSING

ELEMENT IN

CONDENSER

WATER SUPPLY

TO ABSORBER

DISCHARGE OF

ABSORPTION

CHILLER

CONDENSER

WATER PUMP

CWR

TO

COOLING

TOWER

COOLING TOWER

BYPASS

C2690

Loading...

Loading...