ENGINEERING MANUAL OF AUTOMATIC CONTROL

VALVE SELECTION AND SIZING

442

REPRINTED BY PERMISSION FROM ASHRAE HANDBOOK—

1996 HVAC SYSTEMS AND EQUIPMENT

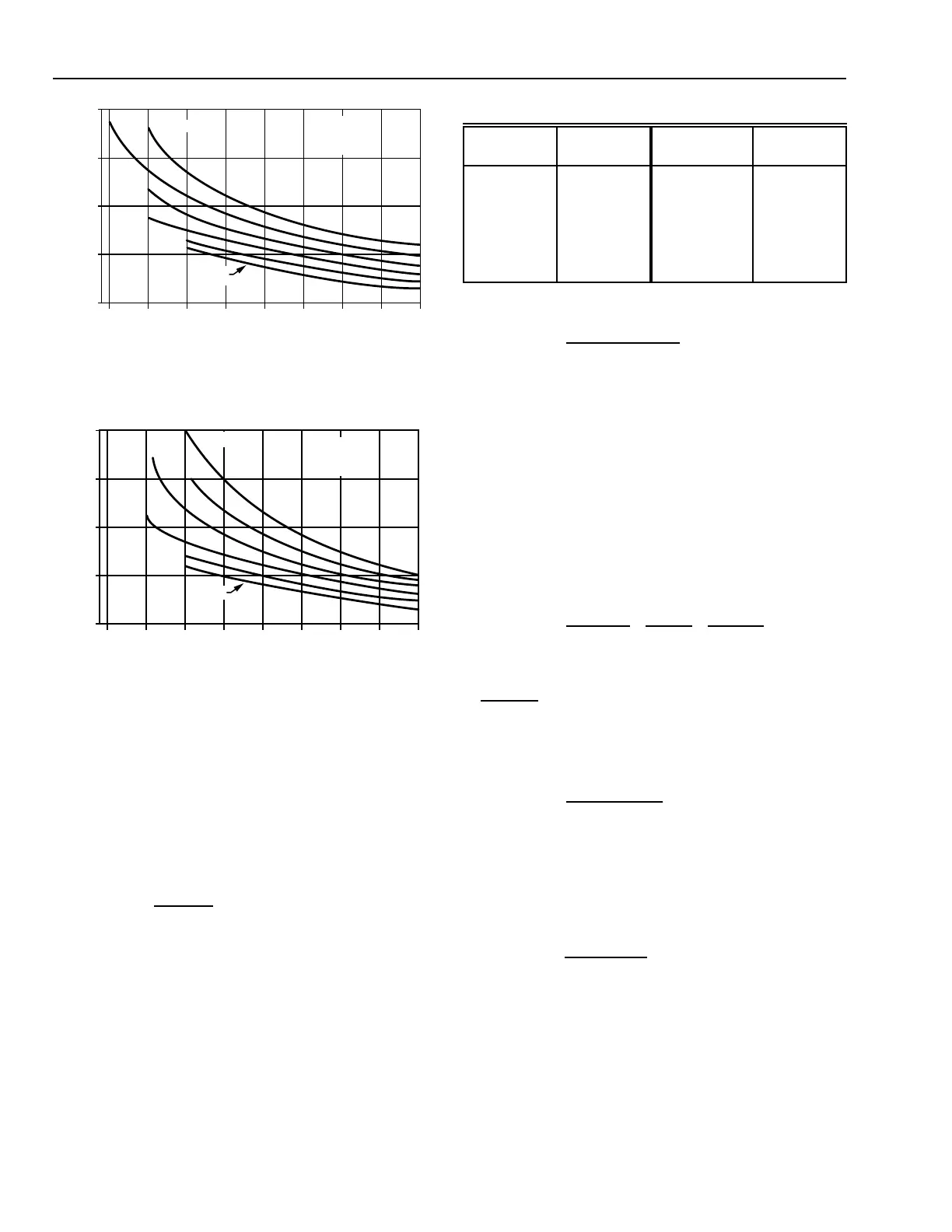

Fig. 14. Pressure Drop Correction for

Ethylene Glycol Solutions.

Table 3. Water Flow Formula Table.

0

0.8

1.0

1.2

1.4

1.6

40 80 120 160

PRESSURE DROP CORRECTION FACTOR

TEMPERATURE, °F

ETHYLENE

GLYCOL

SOLUTION

WATER

M12226

10%

20%

30%

40%

50% BY MASS

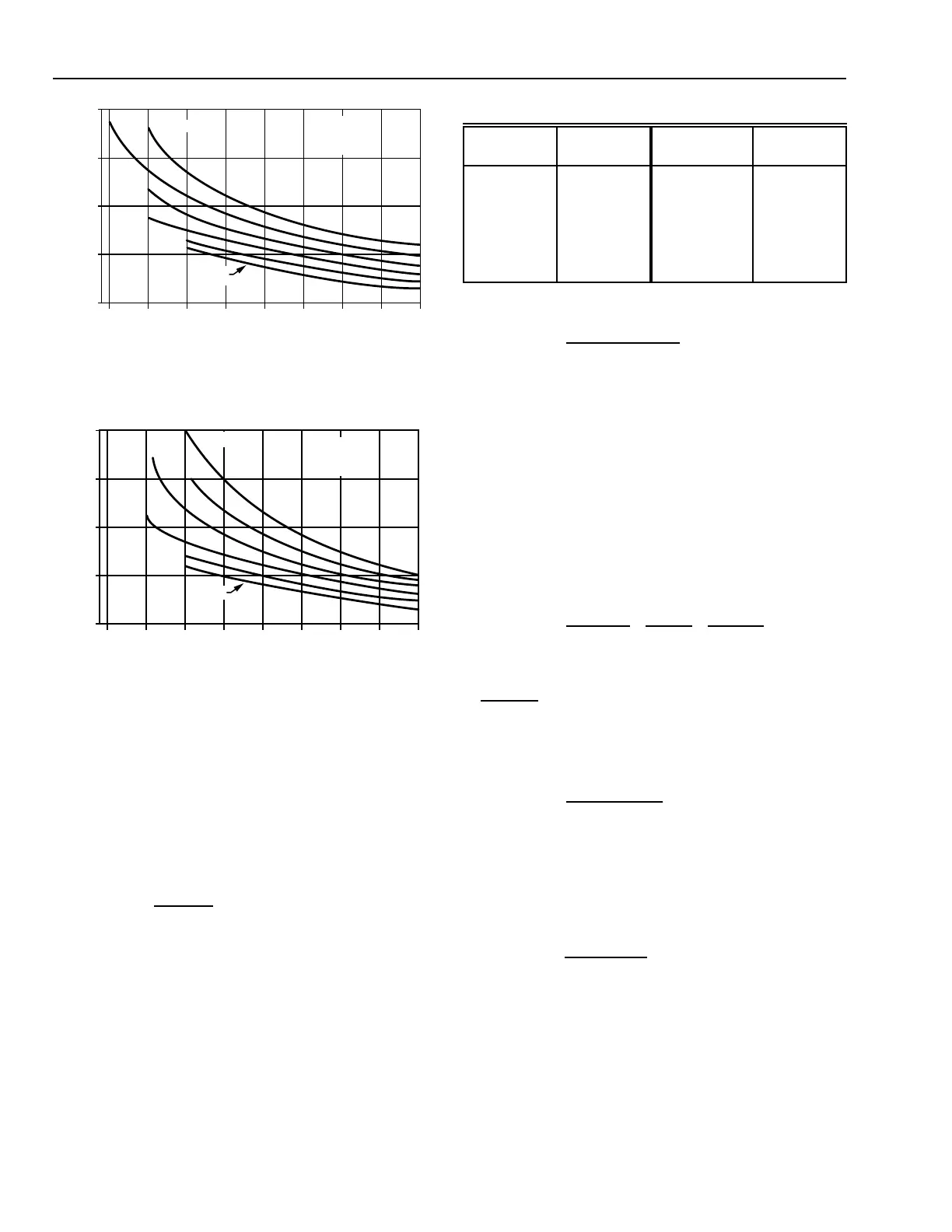

0

0.8

1.0

1.2

1.4

1.6

40 80 120 160

PRESSURE DROP CORRECTION FACTOR

TEMPERATURE, °F

PROPYLENE

GLYCOL

SOLUTION

WATER

M12227

10%

20%

30%

40%

50% BY MASS

REPRINTED BY PERMISSION FROM ASHRAE HANDBOOK—

1996 HVAC SYSTEMS AND EQUIPMENT

Fig. 15. Pressure Drop Correction for

Propylene Glycol Solutions.

QUANTITY OF WATER

To find the quantity of water (Q) in gallons per minute use

one of the following formulas:

1. When Btu/hr is known:

Where:

Btu/hr = Heat output.

K=Va lue from Table 3; based on temperature of

water entering the coil. The value is in

pounds per gallon x 60 minutes per hour.

TD

w

=Temperature difference of water entering

and leaving the coil.

Q =

Btu/hr

K x TD

w

2. For hot water coil valves:

Where:

cfm = Airflow through the coil.

1.08 = A scaling constant. See Note.

TDa = Temperature difference of air entering and

leaving the coil.

K=Va lue from Table 3; based on temperature of

water entering the coil (pounds per gallon x

60 minutes per hour).

TDw = Temperature difference of water entering

and leaving the coil.

NOTE: The scaling constant 1.08 is derived as

follo ws:

Q =

cfm x 1.08 x T

a

K x TD

w

Where:

1 lb air

13.35 ft

3

=

The specific volume of air at standard

conditions of temperature and atmospheric

pressure.

Simplifying the equation:

To find the scaling constant for air conditions other

than standard, divide 14.40 Btu by specific volume of

air at those conditions.

3. For fan system chilled water coil valves:

Where:

cfm = Airflow through the coil.

Btu/lb = Heat per pound of dry air removed. Includes

both sensible and latent heat.

113 = A scaling constant.

TDw = Temperature difference of water entering

and leaving the coil.

1.08 =

0.24 BTU

lb air ˚F

x

60 min

1 hr

x

1 lb ai

13.35 ft

3

1.08 =

14.40 Btu mi

˚F hr 13.35 f

3

Q =

cfm x Btu/l

113 x TD

w

Water

Temp F K

Water

Temp F K

40

60

80

100

120

150

180

502

500

498

496

495

490

487

200

225

250

275

300

350

400

484

483

479

478

473

470

465

Loading...

Loading...