ENGINEERING MANUAL OF AUTOMATIC CONTROL

CONTROL FUNDAMENTALS

20

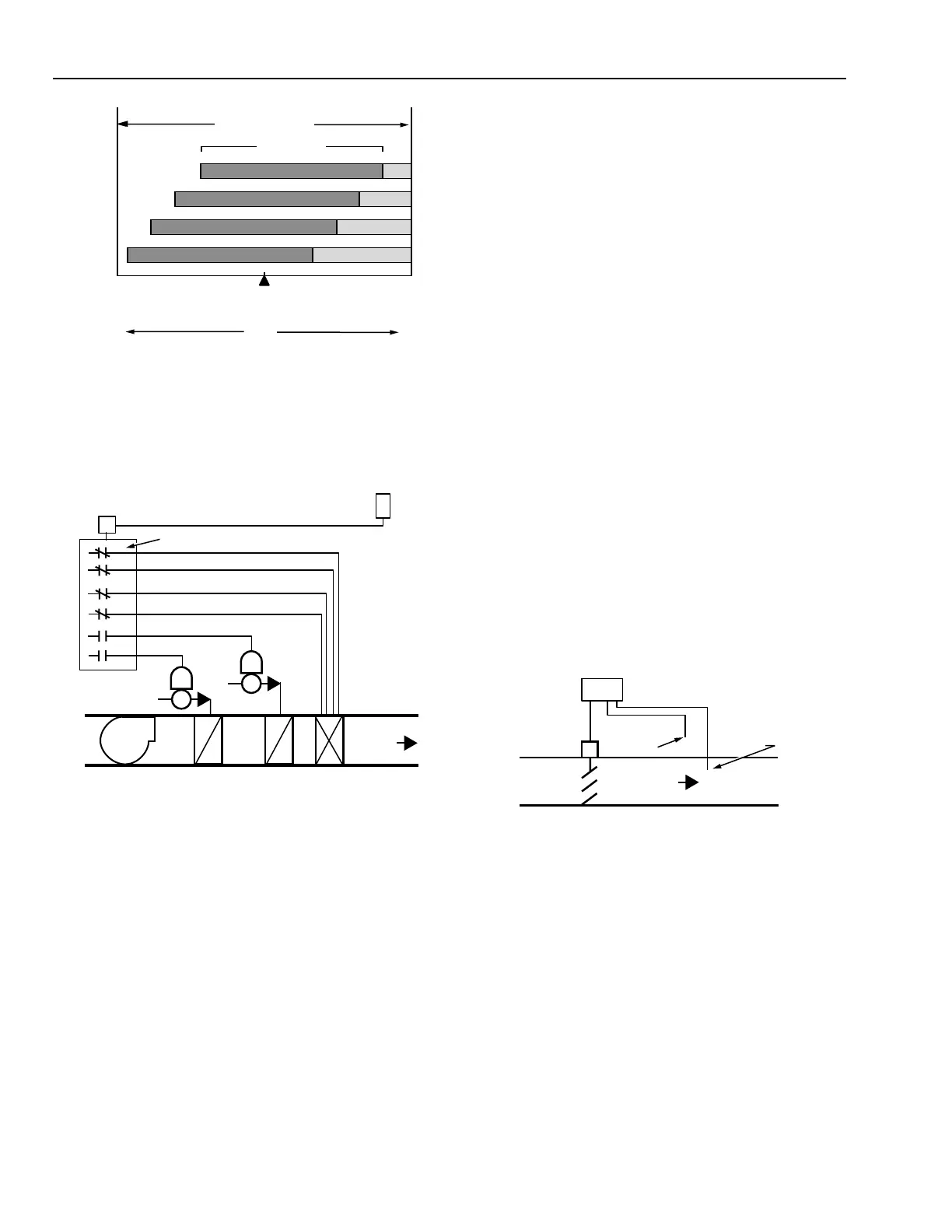

Fig. 27. Staged Reciprocating Chiller Control.

Figure 28 shows step control of sequenced DX coils and

electric heat. On a rise in temperature through the throttling

range at the thermostat, the heating stages sequence off. On a

further rise after a deadband, the cooling stages turn on in

sequence.

ACTUATOR

AIRFLOW

DAMPER

REFERENCE

PRESSURE

PICK-UP

STATIC

PRESSURE

PICK-UP

FLOATING

STATIC

PRESSURE

CONTROLLER

C2717

zero, and the sequence repeats until all stages required to meet

the load condition are on. On a decrease in load, the process

reverses.

With microprocessor controls, step control is usually done

with multiple, digital, on-off outputs since software allows

easily adjustable on-to-off per stage and interstage differentials

as well as no-load and time delayed startup and minimum on

and off adjustments.

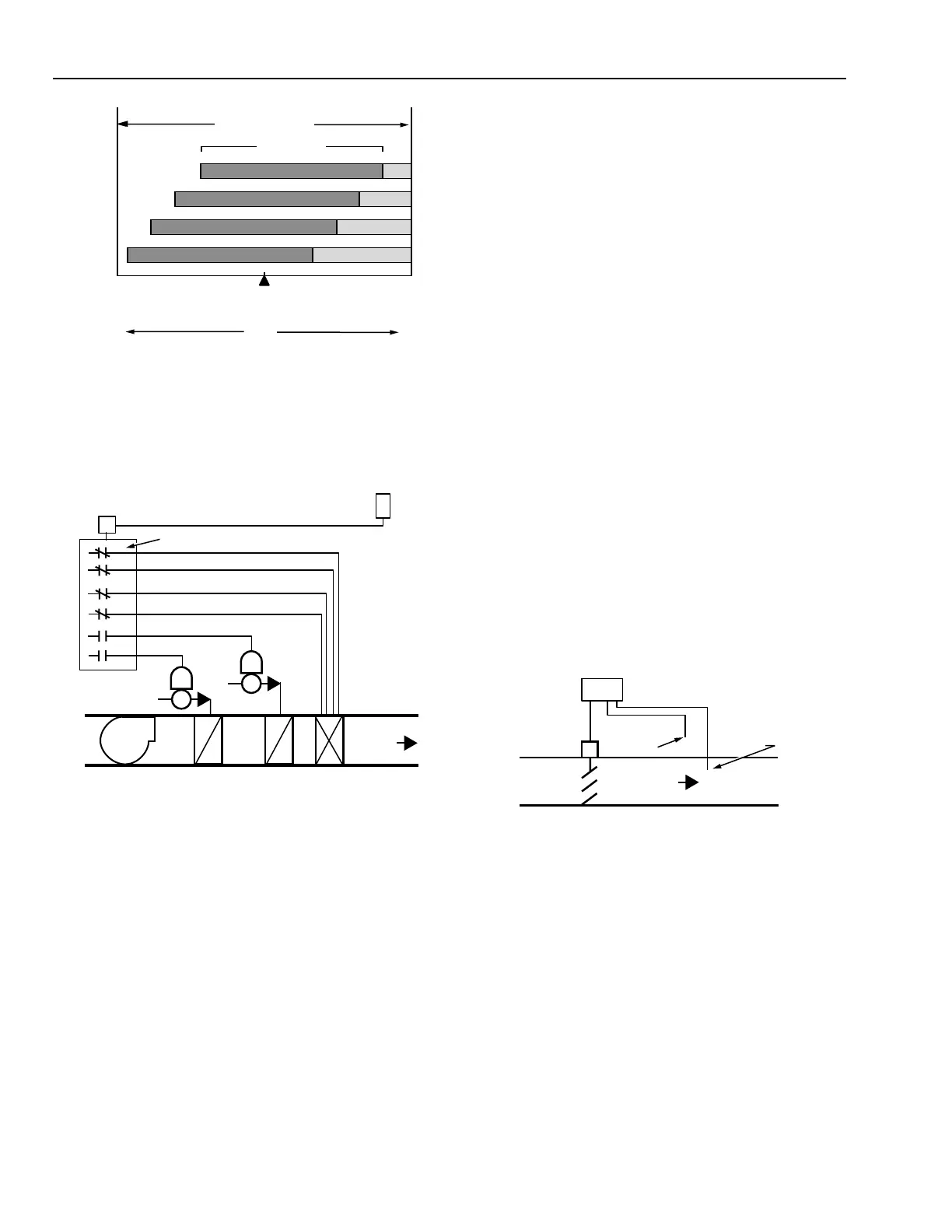

FLOATING CONTROL

Floating control is a variation of two-position control and is

often called “three-position control”. Floating control is not a

common control mode, but is available in most microprocessor-

based control systems.

Floating control requires a slow-moving actuator and a fast-

responding sensor selected according to the rate of response

in the controlled system. If the actuator should move too slowly,

the controlled system would not be able to keep pace with

sudden changes; if the actuator should move too quickly, two-

position control would result.

Floating control keeps the control point near the setpoint at

any load level, and can only be used on systems with minimal

lag between the controlled medium and the control sensor.

Floating control is used primarily for discharge control systems

where the sensor is immediately downstream from the coil,

damper, or device that it controls. An example of floating

control is the regulation of static pressure in a duct (Fig. 29).

ON

OFF

ONOFF

ONOFF

ONOFF

4

3

2

1

DIFFERENTIAL

THROTTLING RANGE

76

SPACE TEMPERATURE (°F)

72

100%

0%

LOAD

C2093

STAGES

74

SETPOINT

SPACE OR

RETURN AIR

THERMOSTAT

ACTUATOR

SOLENOID

VALVES

FAN

DISCHARGE

AIR

DIRECT EXPANSION

COILS

MULTISTAGE

ELECTRIC HEAT

STEP

CONTROLLER

STAGE NUMBERS

6

5

4

3

2

1

C2716

D

X

D

X

Fig. 28. Step Control with Sequenced DX Coils and

Electric Heat.

A variation of step control used to control electric heat is

step-plus-proportional control, which provides a smooth

transition between stages. This control mode requires one of

the stages to be a proportional modulating output and the others,

two-position. For most efficient operation, the proportional

modulating stage should have at least the same capacity as

one two-position stage.

Starting from no load, as the load on the equipment increases,

the modulating stage proportions its load until it reaches full

output. Then, the first two-position stage comes full on and

the modulating stage drops to zero output and begins to

proportion its output again to match the increasing load. When

the modulating stage again reaches full output, the second two-

position stage comes full on, the modulating stage returns to

Fig. 29. Floating Static Pressure Control.

In a typical application, the control point moves in and out

of the deadband, crossing the switch differential (Fig. 30). A

drop in static pressure below the controller setpoint causes the

actuator to drive the damper toward open. The narrow

differential of the controller stops the actuator after it has moved

a short distance. The damper remains in this position until the

static pressure further decreases, causing the actuator to drive

the damper further open. On a rise in static pressure above the

setpoint, the reverse occurs. Thus, the control point can float

between open and closed limits and the actuator does not move.

When the control point moves out of the deadband, the

controller moves the actuator toward open or closed until the

control point moves into the deadband again.

Loading...

Loading...