ENGINEERING CMANUAL OF AUTOMATION CONTROL

AIR HANDLING SYSTEM CONTROL APPLICATIONS

239

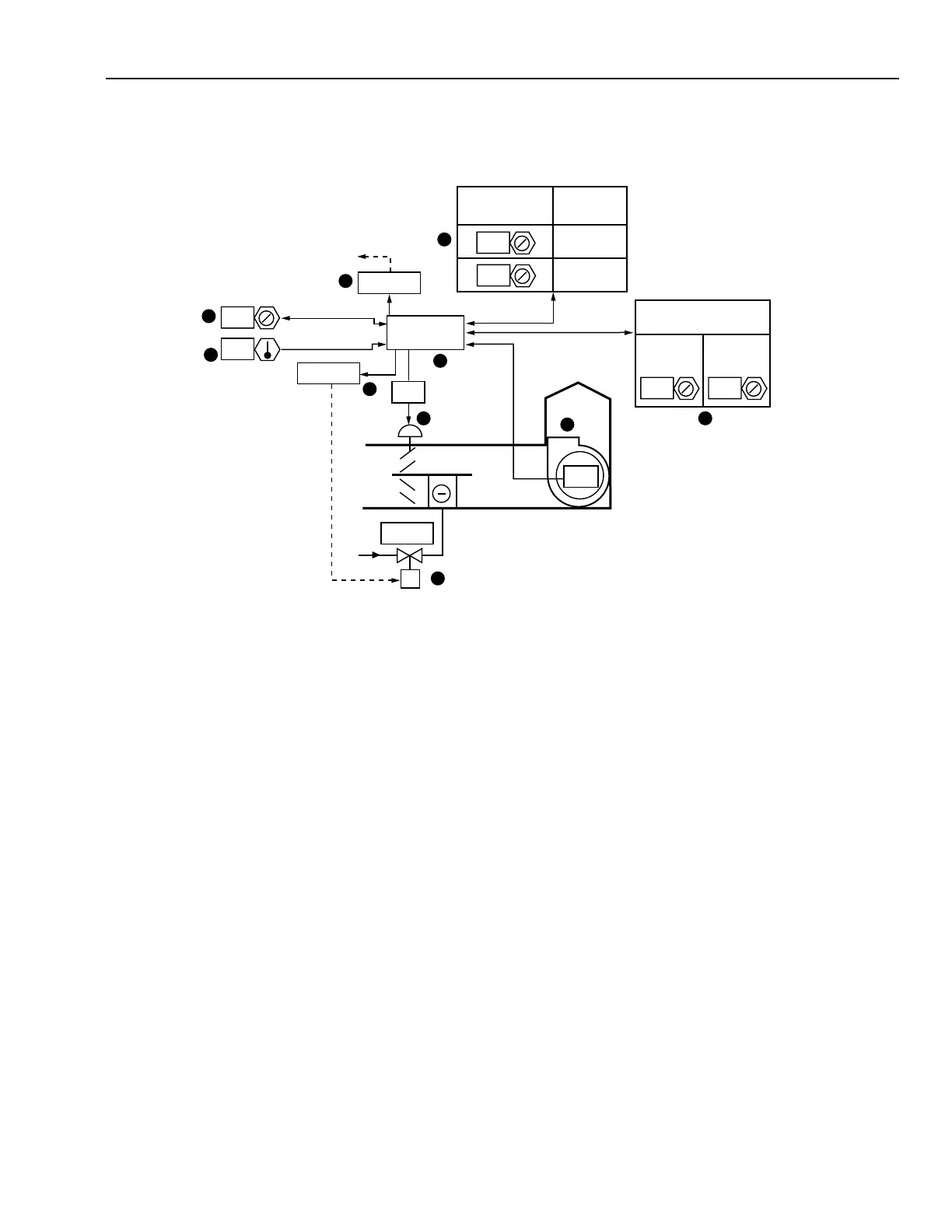

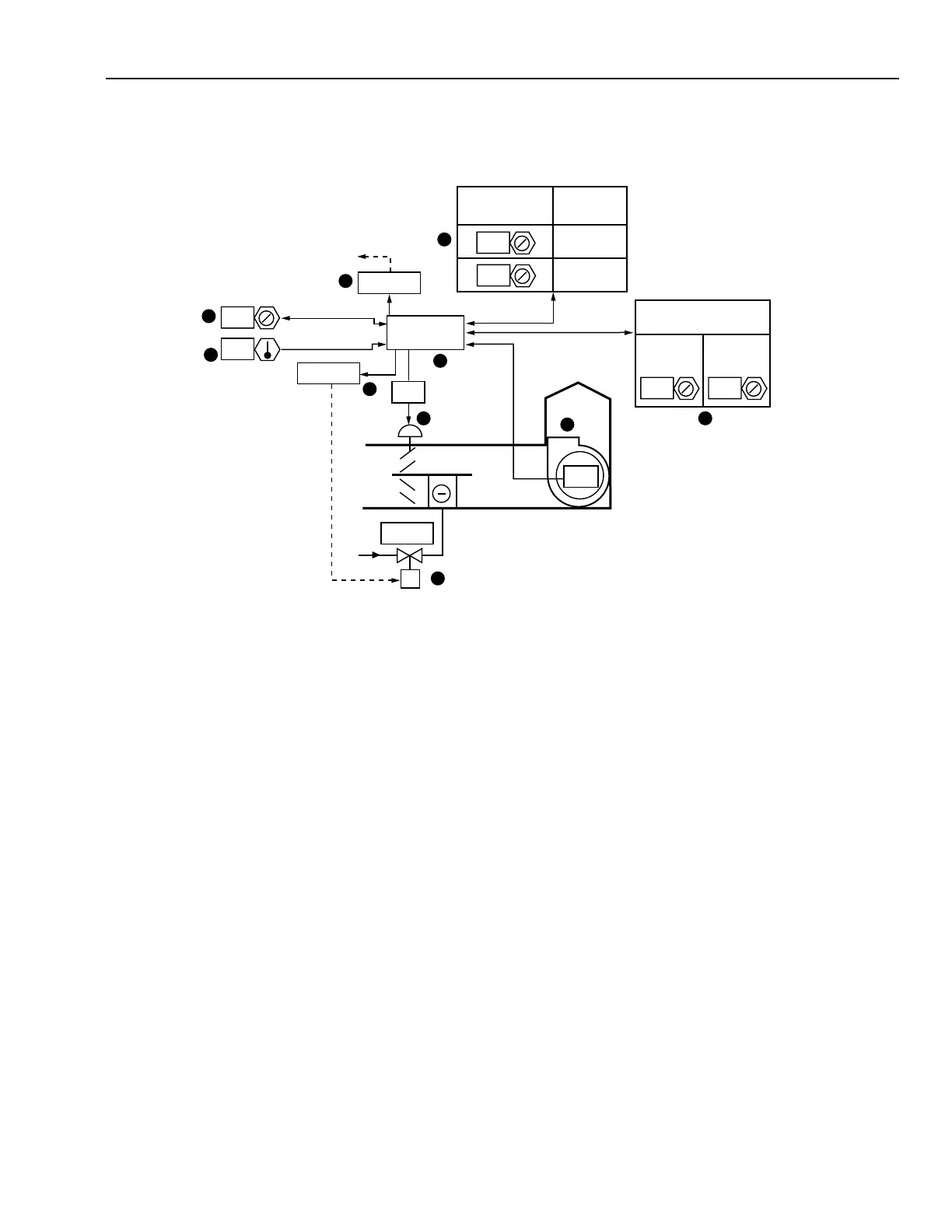

TWO-POSITION CONTROL OF DIRECT EXPANSION COIL SYSTEM—

MODULATING FACE AND BYPASS DAMPER

Functional Description

M10471

7

MA

SA

ON

1

9

8

10

MINIMUM

ON TIME

MINIMUM

OFF TIME

COMPRESSOR

(MINUTES)

8

5

10

4

6

RELAY

RELAY

OPEN

CONTROL

PROGRAM

3

2

76

76

81

SUPPLY

FAN

TO COMPRESSOR

START CIRCUIT

80

30

FACE DAMPER

PERCENT OPEN

SOLENOID

POSITION

OPEN

CLOSED

Item

No. Function

1 Control system energizes when fan is turned

on (See FAN SYSTEM START-STOP

CONTROL).

2,3 Space temperature sensor inputs to PID

control loop to maintain setpoint.

4Face and bypass damper modulates for

cooling control.

5 Damper position determines compressor mode.

6,7 Refrigerant liquid line solenoid valve cycles

for cooling.

8 Relay energizes compressor.

9Timers protect compressor from short cycling.

10 Control program coordinates temperature,

compressor, and fan interlock control.

FEATURES

1. The proportions of air passing through and around the

coil are varied by modulating face and bypass dampers.

2. Lowering air velocity through the coil lowers the moisture

content of air leaving the coil, thus producing lower space

RH than systems that only cycle the refrigeration at a

constant air volume.

CONDITIONS FOR SUCCESSFUL OPERATION

1. Capacity control of refrigeration provided to avoid icing

under light load.

LIMITATIONS

1. Direct expansion coils are difficult to control from SA

due to the large and rapid temperature drop when

energized.

2. Compressor operating and safety controls must be

incorporated into the control system.

3. The system may be controlled from SA if necessary, but

only if the sensor is located far enough downstream of

the coil to ensure complete mixing of the air and software

timers are provided to prevent compressor short cycling.

Hot gas bypass may be required.

Loading...

Loading...