ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

363

Fig. 90. Effect of Flow Control on Finned

Tube Radiator Heat Output.

Supply Hot Water Temperature Control

With Flow Control

Combining flow control with supply water temperature reset

from outdoor air temperature or any other measurement of load

results in effective control.

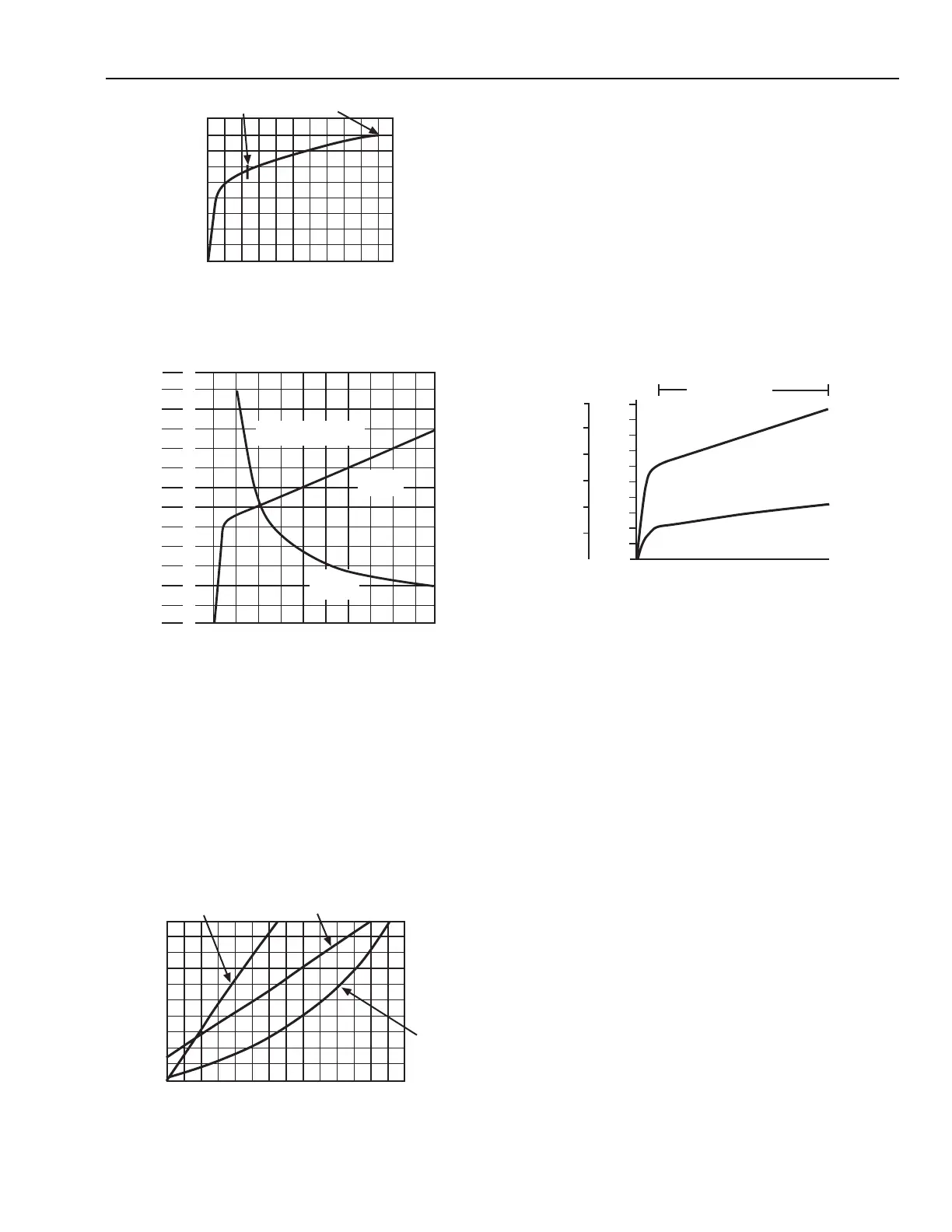

Figure 93 shows output of a typical air heating coil with flow

and supply water temperature control. When 110F water is

supplied during light load conditions, the maximum air

temperature rise through the coil is only 10F. With the proper

water temperature reset schedule, the control valve stays in the

30 to 100 percent open range where flow control output is linear.

Thus, radical changes from desired output do not occur. This is

true for radiators, finned tubes, and reheat coils.

75% FLOW REDUCTION

FLOW, GPM

HEAT OUTPUT %

100

75

50

25

0

10 20 30 40 50

RATED OUTPUT

C2404-1

130

120

110

100

90

80

70

60

50

40

30

20

10

0

50

45

40

35

30

25

20

15

10

0

0102030405060708090100

PERFORMANCE CURVE FOR HOT WATER COIL

200°F ENTERING WATER

80°F ENTERING AIR

HEAT

OUTPUT

TEMP

DROP OF

WATER

TEMP DROP OF WATER (DEGREES F)

1000 BTU/HOUR (MBH)

PERCENT FLOW

C2408-1

Fig. 91. Effect of Flow Control on Hot

Water Coil Heat Output.

Supply Hot Water Temperature Control

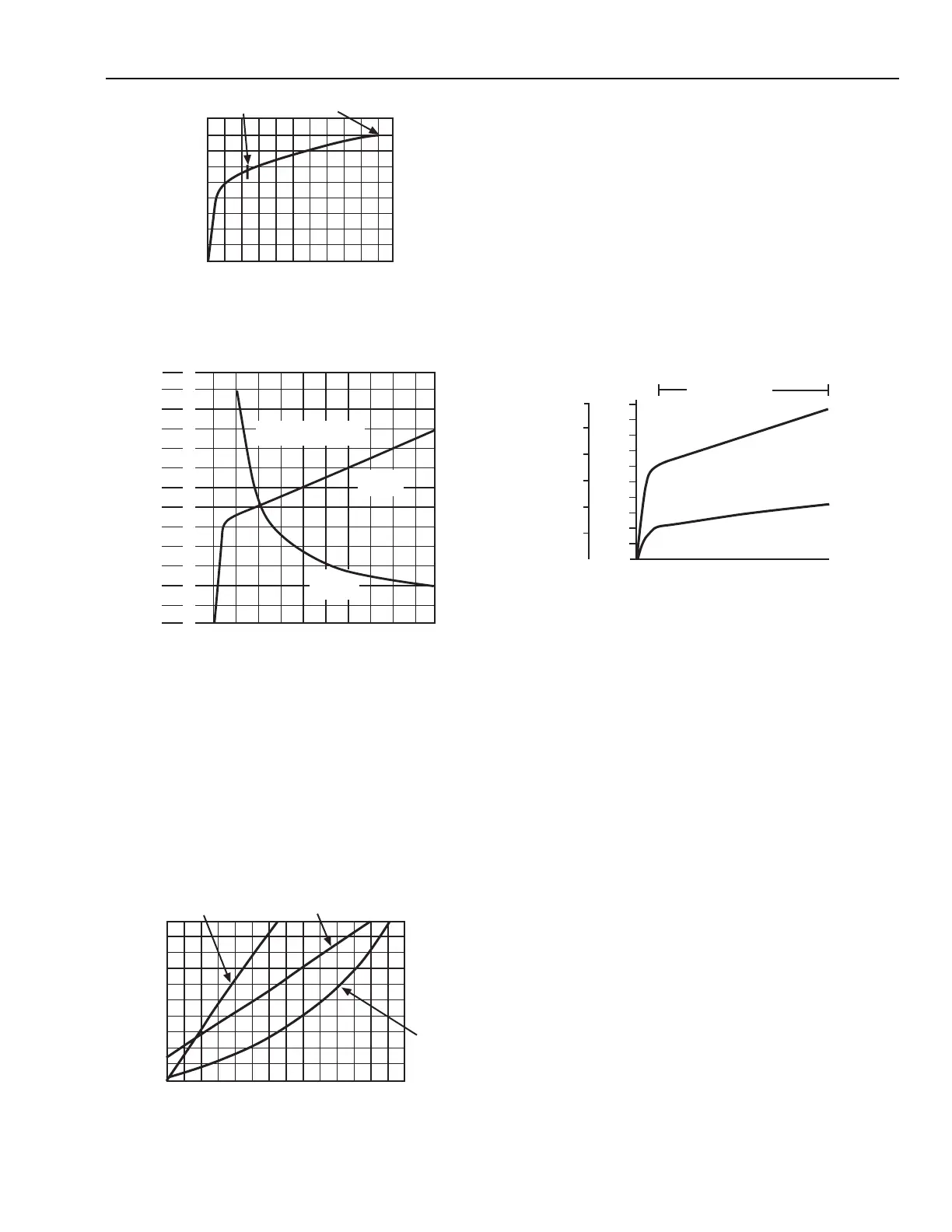

If supply water temperature is varied (reset) in response to a

change in heating load, heat output varies almost linearly (Fig.

92). This mode of control appears ideal, except that it is

impractical to provide a different hot water temperature to each

heating coil or piece of radiation in a building. Varying supply

water temperature as a function of outdoor temperature provides

a good compromise.

Fig. 92. Supply Water Temperature vs

Heat Output at Constant Flow.

HOT WATER

UNIT HEATER

RADIANT

PANEL

CONVECTORS

AND

RADIATORS

100

90

80

70

60

50

40

30

20

10

0

80 100 150 200

SUPPLY WATER TEMPERATURE °F

HEAT OUTPUT, PERCENT

C2405

Fig. 93. Heat Output of Hot Water Coil

at Two Supply Temperatures.

Hot Water Reset

As previously discussed, reset of hot water supply

temperature is the most effective method of controlling Btu

output of a water supplied heating coil, panel, radiator, or

convector. Btu output of most water supplied heating is

relatively linear with respect to supply water temperature. Water

temperature reset can be provided by a steam to hot water

converter, a three-way valve, or boiler water temperature reset.

Reset of hot water using a steam to hot water converter is

discussed in this section.

HOT WATER CONVERTER

The supply water temperature to the radiant panel (Fig. 94)

is reset by the controller modulating a valve in the converter

steam supply. The controller uses the temperatures at the outdoor

air sensor and the supply water sensor to control the steam

supply valve. The valve is positioned to maintain the converter

discharge water temperature as determined by the reset schedule

and outdoor air temperature. A typical reset schedule is shown

in Table 5.

100

90

80

70

60

50

40

30

20

10

0

012 3456789

30

25

20

15

10

5

0

LINEAR RANGE

OUTPUT

110°F SUPPLY

WATER

OUTPUT

200°F WATER

FLOW-GPM

% OF RATED HEAT OUTPUT

AIR TEMP RISE THRU COIL °F

C2406

Loading...

Loading...