ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

318

COOLING TOWER AND CONDENSER

WATER CONTROL

COOLING TOWER PERFORMANCE

CHARACTERISTICS

The cooling tower dissipates the heat collected from the

building by the chiller and chilled water system by cooling the

condenser water. Evaporatively cooled condenser water will

cool refrigerant to within 7F of the outdoor air wet-bulb

temperature. Air cooled condensers will cool refrigerant to

within 20F of the outdoor air dry-bulb temperature. A cooling

tower normally provides a refrigerant head about 30F lower

than an air cooled condenser. This means an evaporative cooling

tower provides a significantly lower cooling cost than an air

cooled condenser.

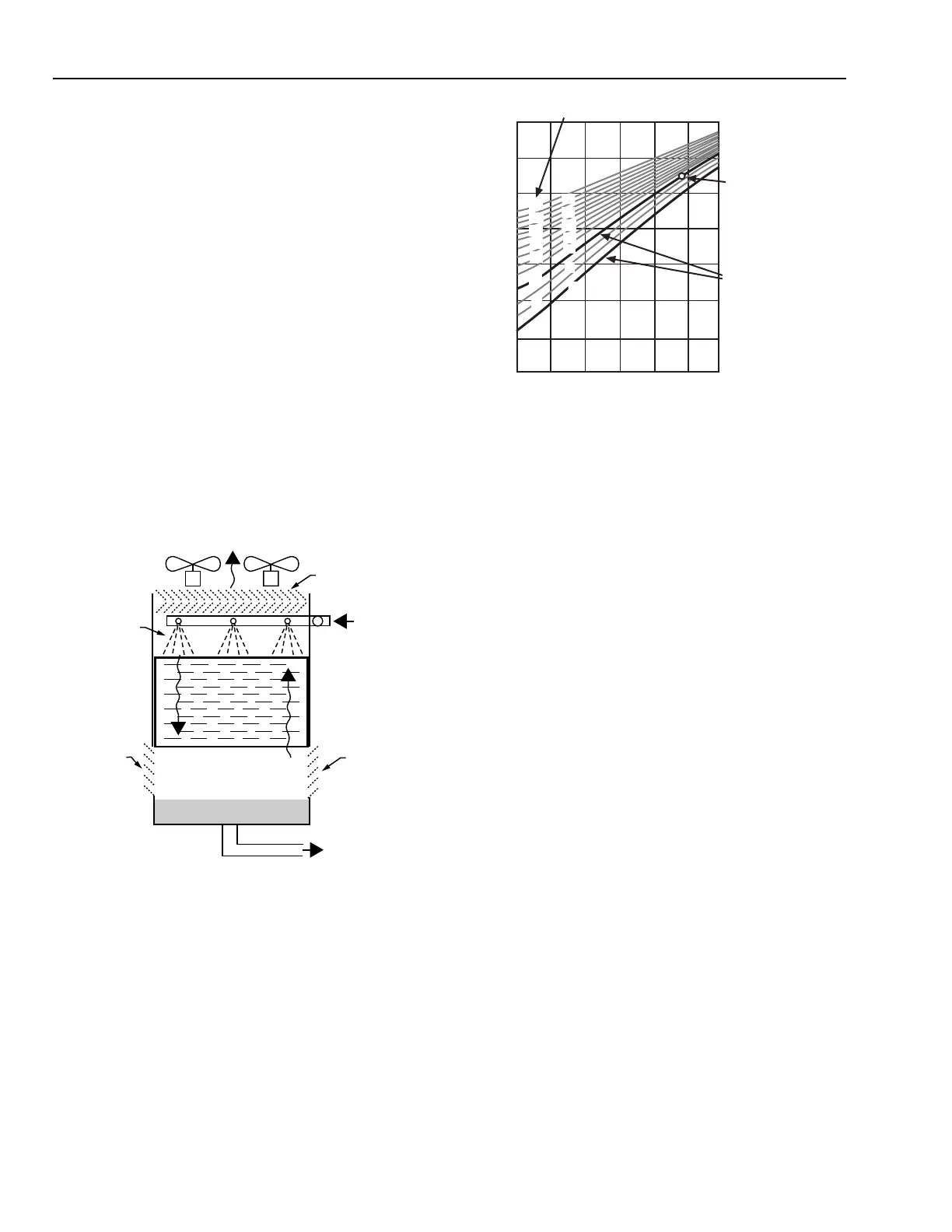

Figure 25 shows water-air counterflow in a cooling tower. The

fill increases the time that the water and air are in contact making

the cooling tower more efficient. Fill is generally one of two types,

either splash or film type. A splash type fill is a series of slats over

which the water cascades. Film type fill causes the water to flow

down thin closely spaced vertical sheets of plastic.

Reprinted by permission from the ASHRAE

Handbook–1996 Systems and Equipment

Fig. 26. Typical Cooling Tower

Partial Load Characteristics.

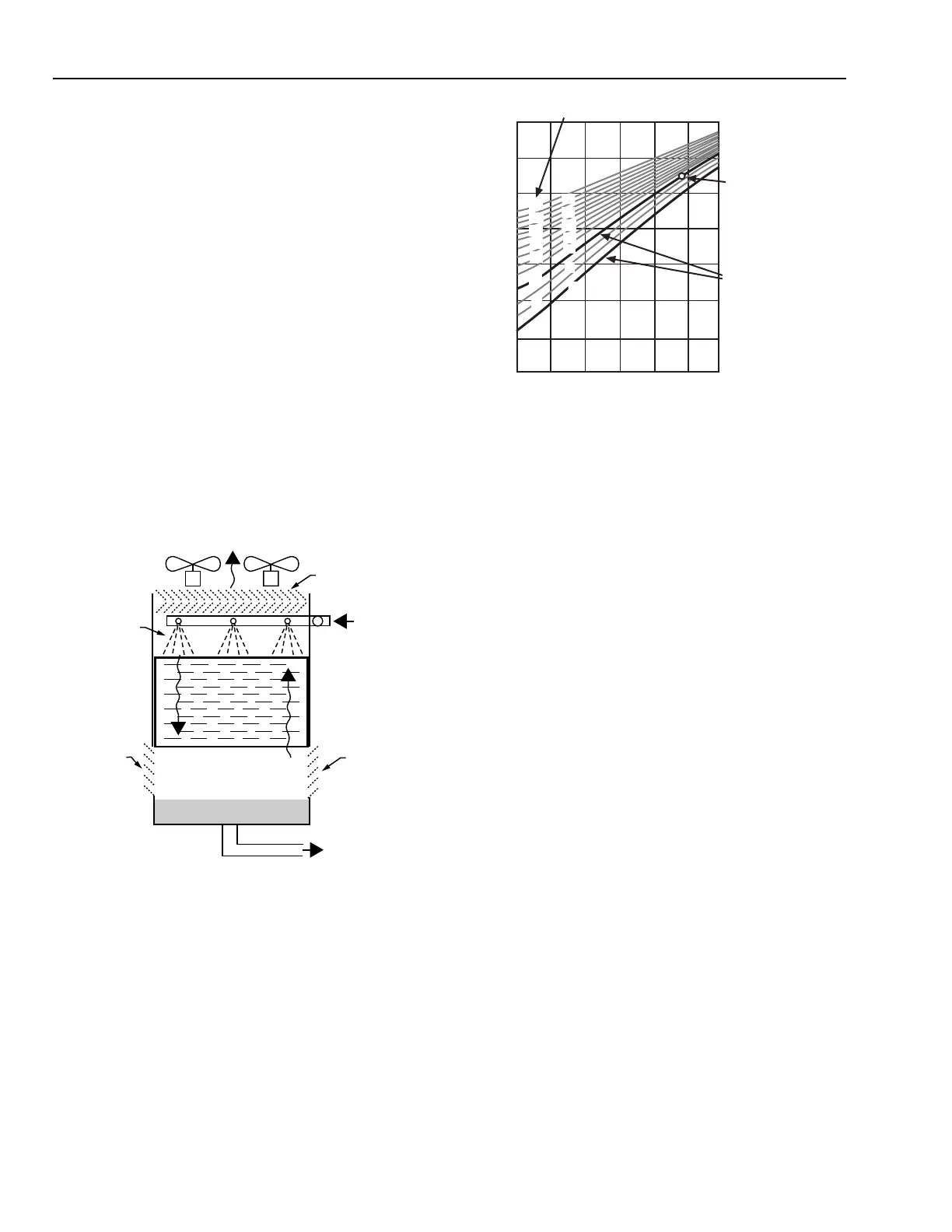

In Figure 26 summer design conditions are approximately

85F cold water leaving the tower, 95F water entering, and OA

wet-bulb of 78F. This is 7F approach at 10F range. Notice that

the point is plotted on the 10F range line. The same tower used

for free cooling at an OA wet-bulb of 50F would provide 65F

leaving water (15F approach) at full load (10F range) or 58F

water (8F approach) at 40 percent load (4F range).

COOLING TOWER CAPACITY CONTROL

Fan control is the usual method of reducing tower capacity

to maintain condenser water supply temperature in mild

weather. A tower bypass valve is used to further limit cooling

when the fans are off (Fig. 27). On-off fan control is very

difficult at light loads because at light load the OA WB is usually

well below design, which increases the tower capacity,

producing short fan “on” periods. Controlling the air volume

with dampers, blade pitch, or fan speed provides much closer

and more stable control. A variable speed fan is more efficient

than a two-speed fan when varying tower capacity.

Modulating tower water bypass for capacity control at low

ambient temperatures can cause freeze-up in some tower designs.

Since, use of a tower bypass mixing valve in the tower leaving

water can lower the pump suction pressure below the pumps

minimum NPSH, a diverting valve in the tower entering water

is generally used.

Fig. 25. Cooling Tower, Showing Water-Air Counterflow.

The range (inlet water temperature minus outlet water

temperature) at design load of a cooling tower is determined

by the amount of heat to be rejected and the water flow used to

carry this heat to the tower. The cooling capability is then

expressed as the design approach (approach specifies how close

to the OA WB a cooling tower can cool water) at design range.

Since most operation is at less than design load and/or design

outdoor air temperatures, partial load operating characteristics

have a strong influence on operating costs. Partial load operating

characteristics are also used to establish the cooling capacity

and capability for free cooling cycles at low outdoor air

temperatures. Partial load characteristics for a tower at design

flow rate are shown in Figure 26.

HEATED

AIR OUT

DRIFT

ELIMINATORS

HOT WATER

FROM

CONDENSER

AIR IN

AIR IN

TO CONDENSER

WATER PUMP

C2694

SPRAY

DISTRIBUTION

FILL

WATER

AIR

FREE COOLING

EXAMPLES

SUMMER DESIGN

CONDITIONS:

ENTERING WATER, 95F

LEAVING WATER, 85F

OA WET BULB, 78F

TEMPERATURE RANGE, °F

WATER TEMPERATURE, °F

100

90

80

70

60

50

40

30

30

40

50

60

70

80

30

26

22

18

14

10

6

28

24

20

16

12

8

4

C1479

OUTSIDE AIR WET BULB TEMPERATURE, °F

Loading...

Loading...