ENGINEERING CMANUAL OF AUTOMATION CONTROL

AIR HANDLING SYSTEM CONTROL APPLICATIONS

233

The following results are obtained:

Item

No. Explanation

1 Coil No. 1 is providing 100 percent capacity

raising the entering air from 35°F to 65°F.

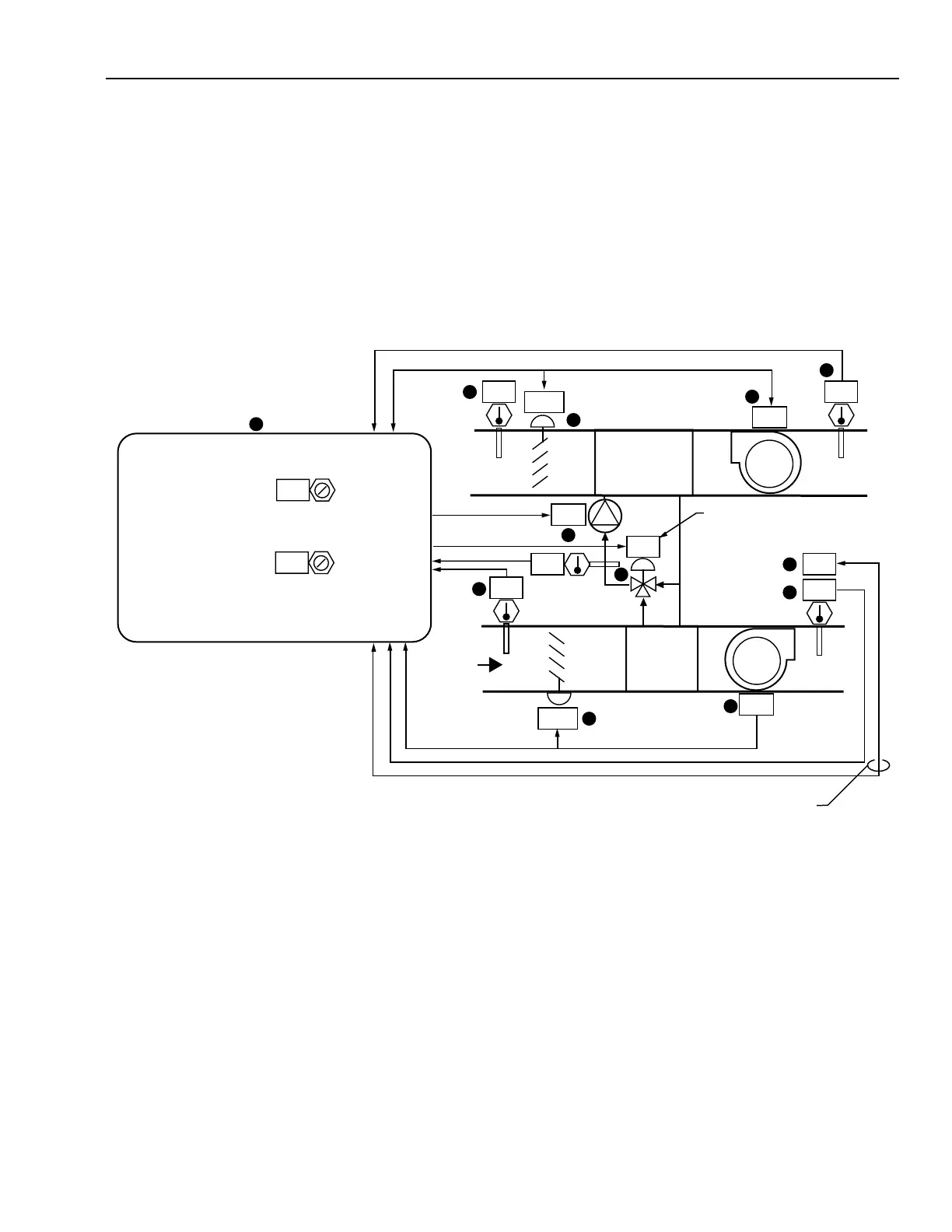

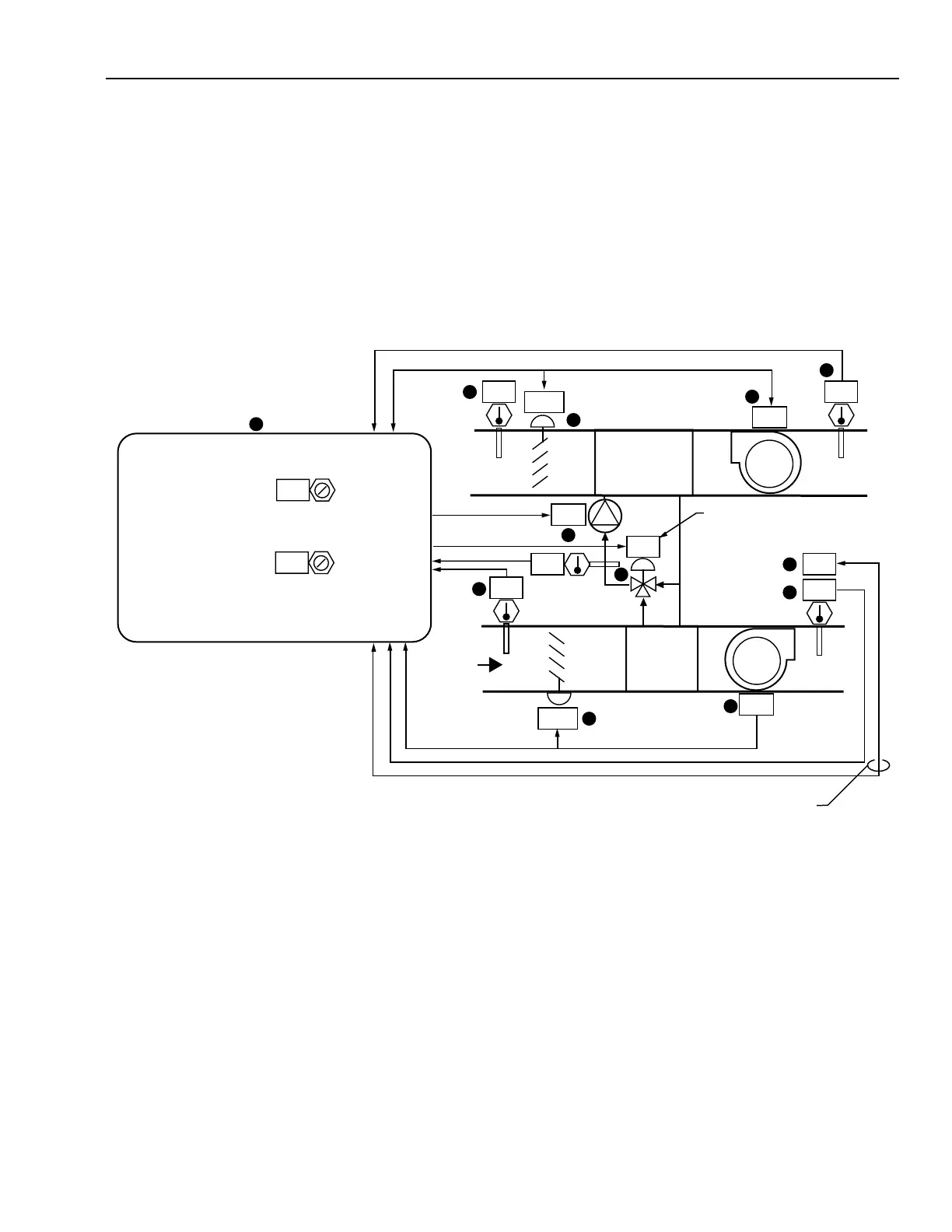

YEAR-ROUND HEAT RECOVERY PREHEAT SYSTEM CONTROL

Functional Description

100

OA

SA

RA

EA

ON

ON

ON

N.C.

PERCENT OPEN

TO SUPPLY COIL

N.C.

N.C.

N.O.

C

SUPPLY

COIL

SETPOINT

SUPPLY FAN

HEATING SETPOINT DETERMINED

BY SUPPLY SYSTEM CONTROLS.

M10474

1

2

8

9

3

10

5

6

7

4

11

12

OPEN

OPEN

79

86

82

55

75

82

EXHAUST

COIL

PUMP

PUMP START SETPOINTS:

COOLING SETPOINT = ANYTIME OA

TEMPERATURE IS DEGREES

ABOVE RA TEMPERATURE.

HEATING SETPOINT = ANYTIME OA

TEMPERATURE IS DEGREES

BELOW SA TEMPERATURE SETPOINT

DETERMINED BY SUPPLY

SYSTEM CONTROL.

3

6

Item

No. Function

1,2 Fans start and enable pump control upon

HVAC demand for ventilation (See FAN

SYSTEM START-STOP CONTROL).

3,4 Dampers close upon fan shutdown.

5 Pump runs when temperature conditions are

suitable for beneficial results.

6,10 The OA and RA temperature difference

determines when pump operation is beneficial.

2 Coil No. 2 valve is closed.

3 Coil No. 3 is modulating and provides a 5°F

temperature rise to the desired supply

temperature.

7Mixing valve prevents too much RA heat

from being transferred such that the SA

temperature exceeds that demanded by the

HVAC control system. Mixing valve also

keeps water entering the exhaust coil from

dropping below freezing to prevent the coil

from frosting.

8,9 HVAC system SA temperature setpoint

determines valve position in winter.

11 Operator information.

12 Dynamic graphic sequence display permits

the operator to adjust program setpoints.

Loading...

Loading...