ENGINEERING CMANUAL OF AUTOMATION CONTROL

AIR HANDLING SYSTEM CONTROL APPLICATIONS

237

CONDITION FOR SUCCESSFUL OPERATION

The water must be supplied at a reasonably constant pressure.

LIMITATIONS

Modulating water flow through a constant air volume chilled

water coil usually causes a rise in space RH because the coil

leaving water temperature rises significantly.

SPECIFICATIONS

The flow of chilled water through the cooling coil shall be

controlled by a three-way valve modulated by a space

temperature PI control loop. The valve shall close to the coil

upon fan shutdown and open to the coil upon loss of actuator

motive force.

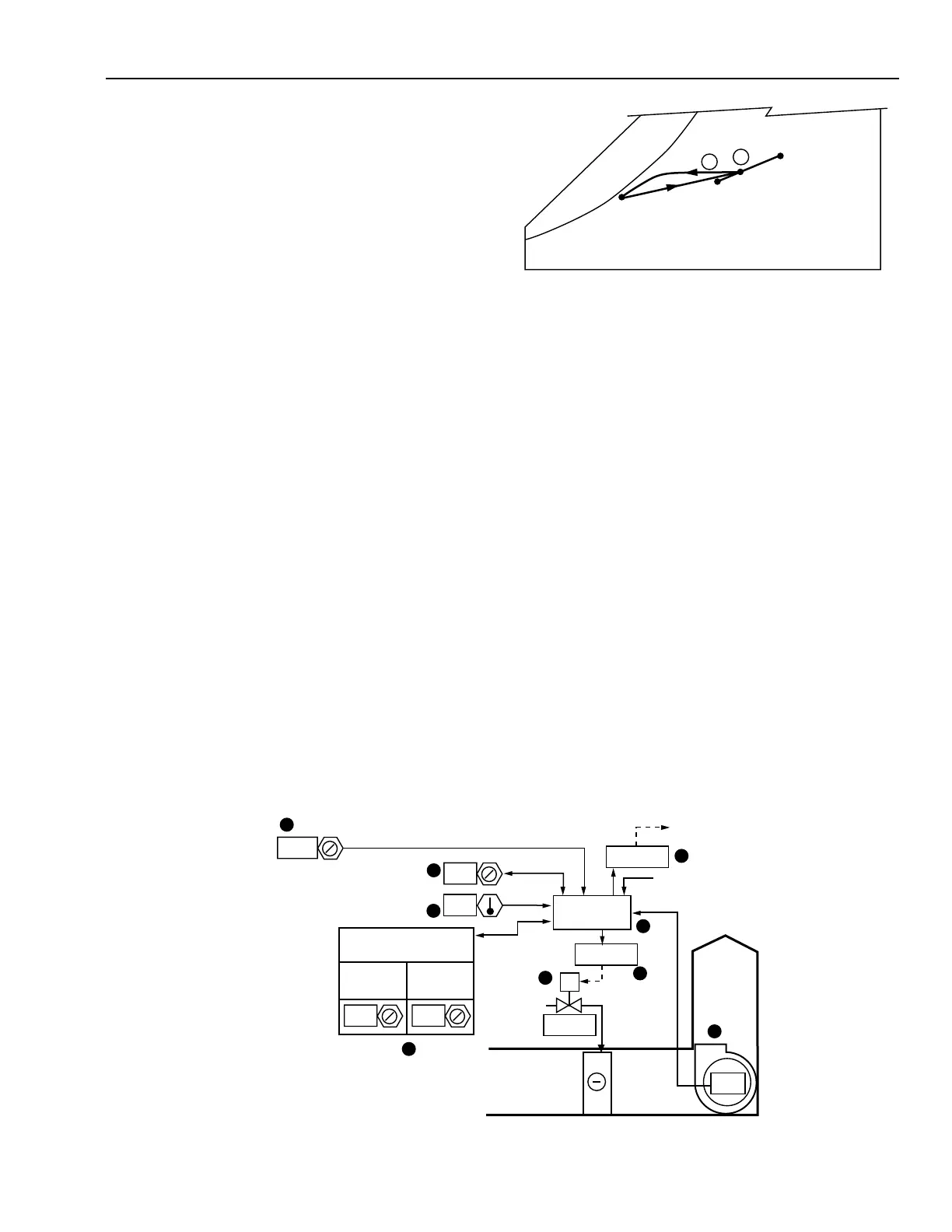

PSYCHROMETRIC ASPECTS

The temperature, and often moisture content, of leaving air

increases as the sensible cooling load lightens.

In the following chart it is assumed that:

1. Desired space and RA condition is 78°F DB and 50%

RH (65°F WB).

2. Design OA temperature is 95°F DB and 75°F WB.

3. Air entering the system is from the ECONOMIZER

CYCLE DECISION application. This system operates

on 35 percent OA during the cooling cycle.

4. Coil discharge temperature is 55°F.

C2558-2

OA 95°F DB,

75°F WB

RA 78°F DB,

50% RH

SA 55°F DB

2

1

MA

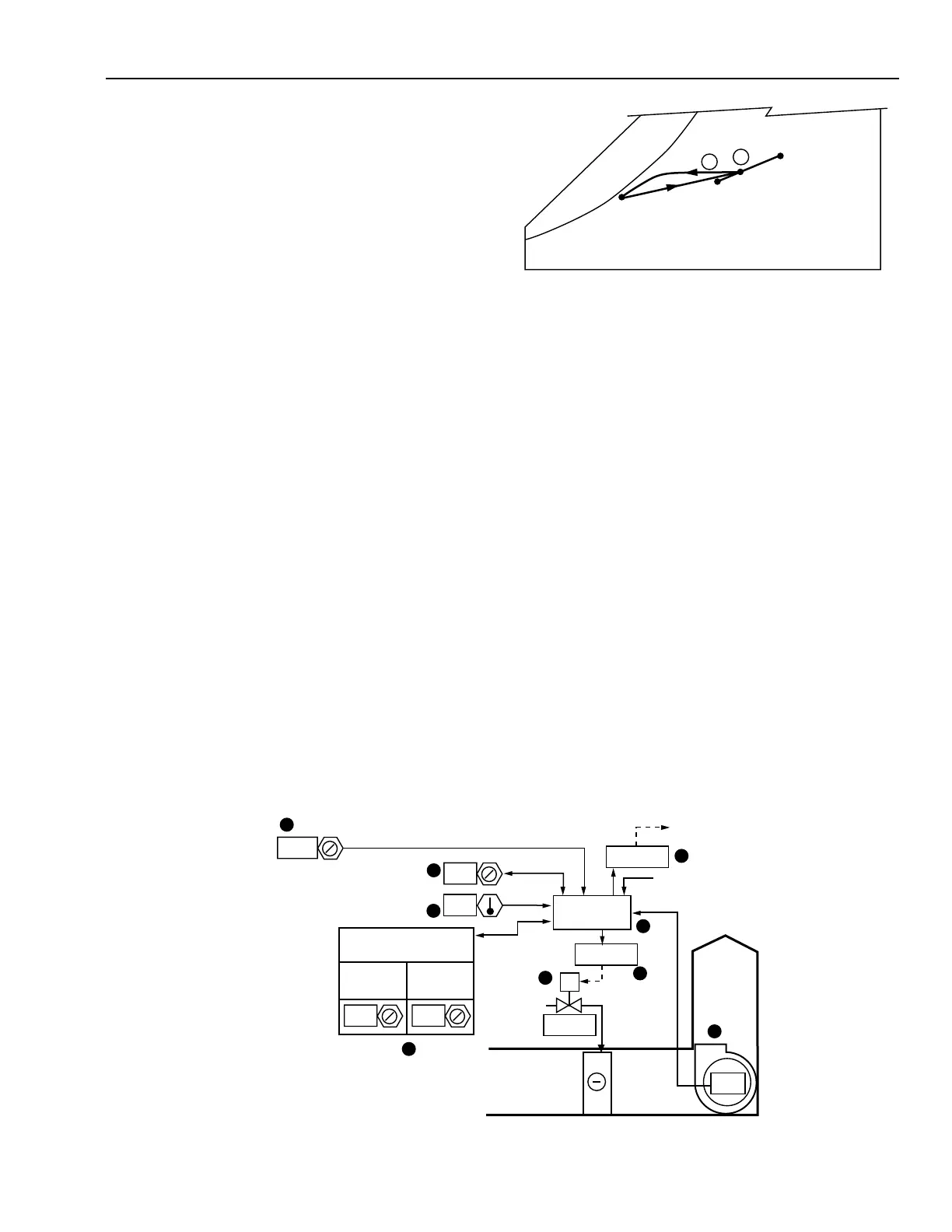

TWO-POSITION CONTROL OF DIRECT EXPANSION COIL SYSTEM

Functional Description

The following results are obtained:

Item

No. Explanation

1Mixed air temperature at cooling design

condition.

2Air entering the coil is cooled along a line of

constant moisture content until saturation is

approached. Near saturation the moisture

content is reduced as the air is cooled. This

process involves both latent and sensible

cooling.

NOTE: Condition of coil leaving air will change with the

cooling load in the space. As the cooling load

decreases, the three-way valve will provide less chilled

water flow to the coil and the discharge air temperature

will rise (approximately along Line 2).

M10470

4

MA

SA

ON

1

8

8

10

MINIMUM

ON TIME

MINIMUM

OFF TIME

COMPRESSOR

(MINUTES)

6

9

5

RELAY

RELAY

OPEN

CONTROL

PROGRAM

3

7

2

76

2.5

76

SUPPLY

FAN

TEMPERATURE CONTROL

DIFFERENTIAL (DEGREES)

TO COMPRESSOR

START CIRCUIT

COMPRESSOR

VOLTAGE MONITOR

Loading...

Loading...