ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

340

Pump Power Requirements

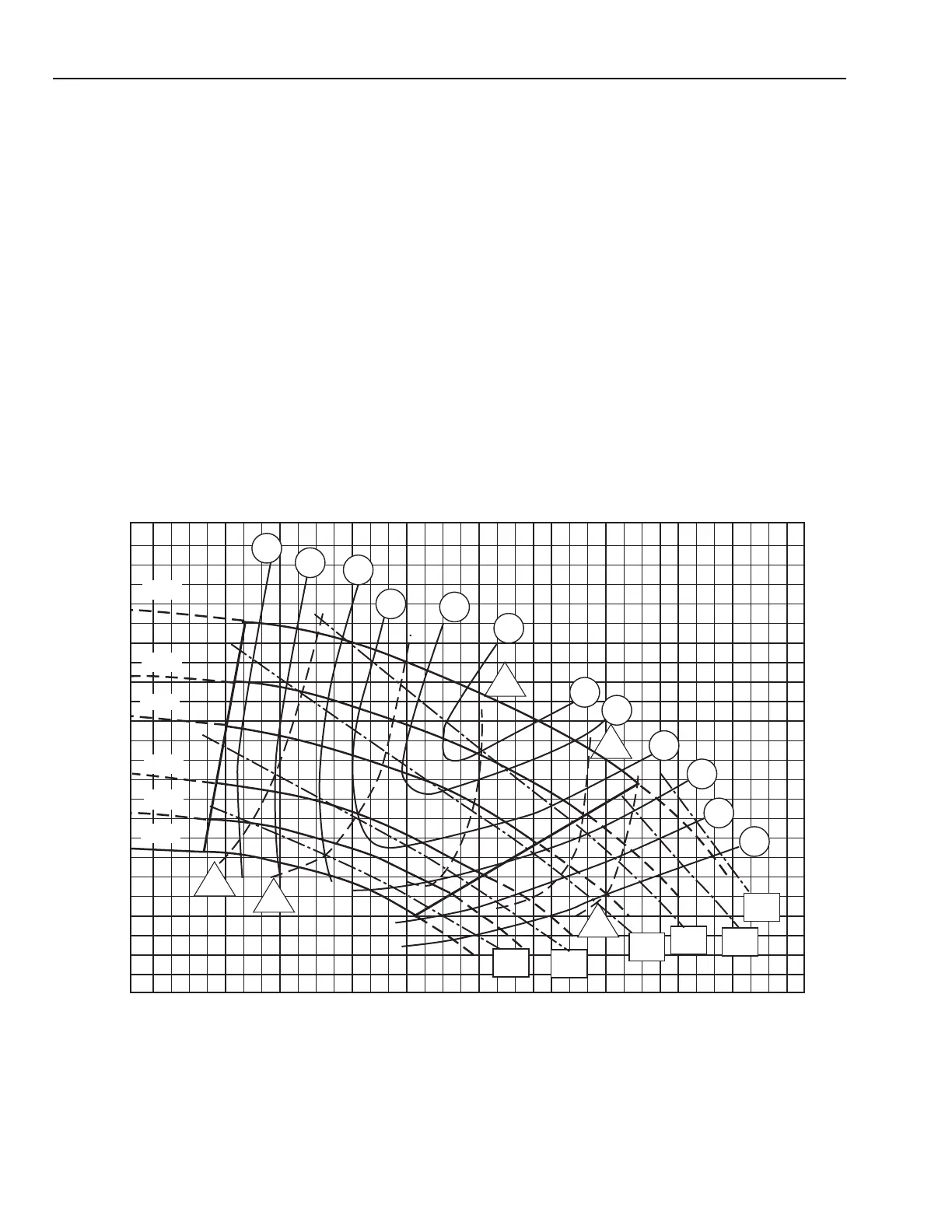

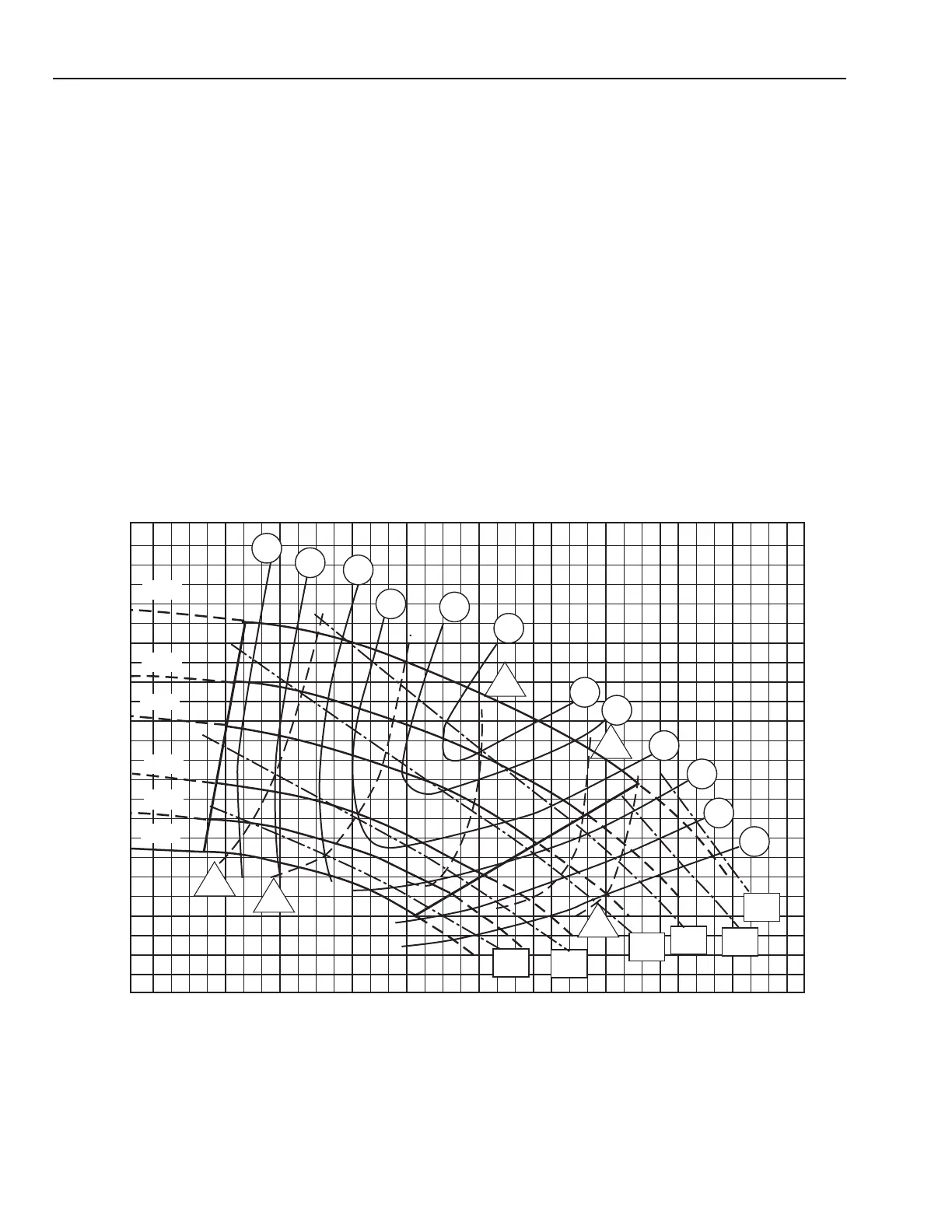

The pump curve in Figure 53 is part of a family of curves for

a pump. Each curve of the family represents a different size

impeller used with the pump at a specified rpm. It relates to the

power input required just to move the water (water horsepower)

as follows:

Water hp = (flow x head x SG) ÷ 3960

Where:

flow = gpm

head = ft

SG = specific gravity of the liquid (water = 1)

The motor driving the pump must have a horsepower rating in

excess of water horsepower to take care of bearing and seal friction,

recirculation within the housing, and impeller efficiency.

NOTE: Water horsepower increases with head and flow. If

flow is allowed to increase, the motor may overload.

Courtesy of Aurora Pump

Fig. 54. 1150 RPM Typical Pump Curve.

Pump Performance Curves

Commercial pumps have performance curves showing the

following data for a given pump speed:

—Total head in ft versus flow in gpm

—Total head versus flow for various impeller diameters

— Pump efficiency at various operating points

—Brake horsepower (BHP) or motor horsepower required

— Net positive suction head (NPSH). NPSH is the absolute

pressure (psia) required at the suction inlet to prevent

cavitation due to “boiling” and formation of bubbles in

the water.

Figure 54 is a typical performance curve showing some of

the preceding data. Impeller diameters are shown on the left.

Pump Efficiency

Pump efficiency is a comparison of water horsepower

developed in the pump and brake horsepower applied by the

motor to the shaft and impeller.

7-1/2

HP

10

HP

15

HP

20

HP

25

HP

30

HP

7

NPSH

8

NPSH

10

NPSH

15

NPSH

20

NPSH

50%

60%

70%

75%

80%

81%

81%

80%

75%

70%

60%

50%

0 200 400 600 800 1000 1200 1400 1600 1800

0

20

40

60

80

100

15"DIA

14"DIA

13"DIA

12"DIA

11"DIA

10"DIA

CAPACITY - G.P.M.

TOTAL HEAD IN FEET

C1053

Loading...

Loading...