ENGINEERING MANUAL OF AUTOMATIC CONTROL

GENERAL ENGINEERING DATA

485

CONDUIT SIZE AND FILL

The fill factor for nonlead covered conductors is 53 percent

for one conductor, 31 percent for two conductors, and 40 percent

for three or more conductors. Table 21 shows internal

dimensions of electrical conduit.

Use the following formula and Tables 21 and 22 to determine

correct conduit size:

A

C

=(NA

W1

+ NA

W2

+ NA

W3

+ ... + NA

WN

) ÷ F

Where:

A

C

= Conduit internal cross-sectional area, in

square inches.

N=Number of conductors of given cross-

sectional area.

A

W

=Cross-sectional area of a given conductor

including insulation, in square inches (see

Table 22).

F=Fill factor, in decimals.

Where:

Cross-sectional area of

No. 18 TFN conductor = 0.0062 in

2

Cross-sectional area of

No. 16 TFN conductor = 0.0079 in

2

Fill factor = 40 percent

Then:

A

C

= [(8 x 0.0062) + (14 x 0.0079)] ÷ 0.4

A

C

= 0.4005 in

2

From Table 21, a 3/4-in. rigid (0.533 in

2

) or flexible conduit

(0.518 in

2

) is required for the conduit run.

If only the diameter (dia) is available:

The cross-sectional area in in

2

= π(dia ÷ 2)

2

.

NOTE: It is obvious from Table 22 that conduit size for a given

mix of conductors can vary depending upon the type

of insulation used.

ELECTRIC MOTORS

Single-phase electric motors are classified by the method used

to start the motor. Table 23 describes the characteristics and

typical applications of single-phase motors by classification.

No special means of starting is required for three-phase motors,

since starting (rotational) torque is inherent in three-phase

motors. A three-phase motor can be reversed by switching any

two phases.

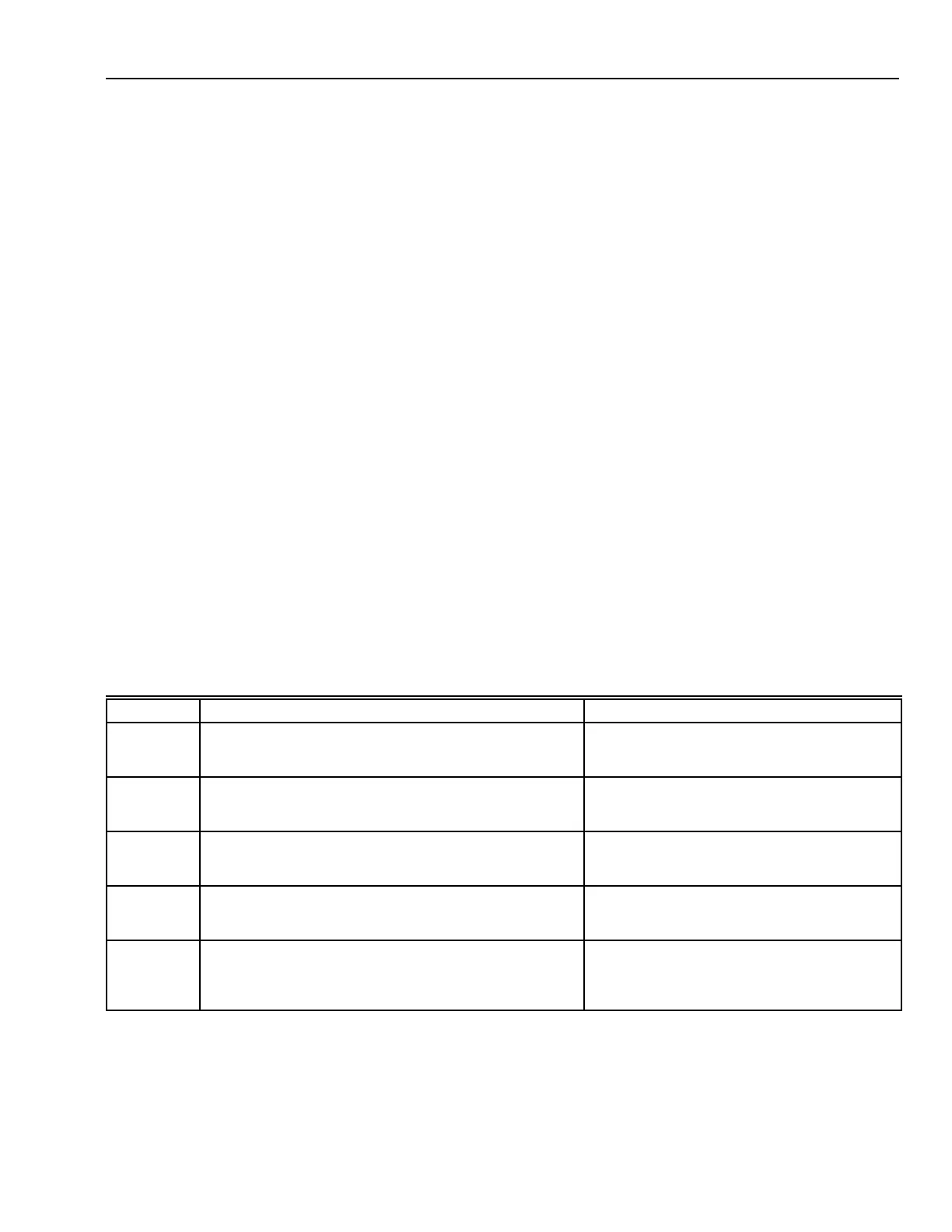

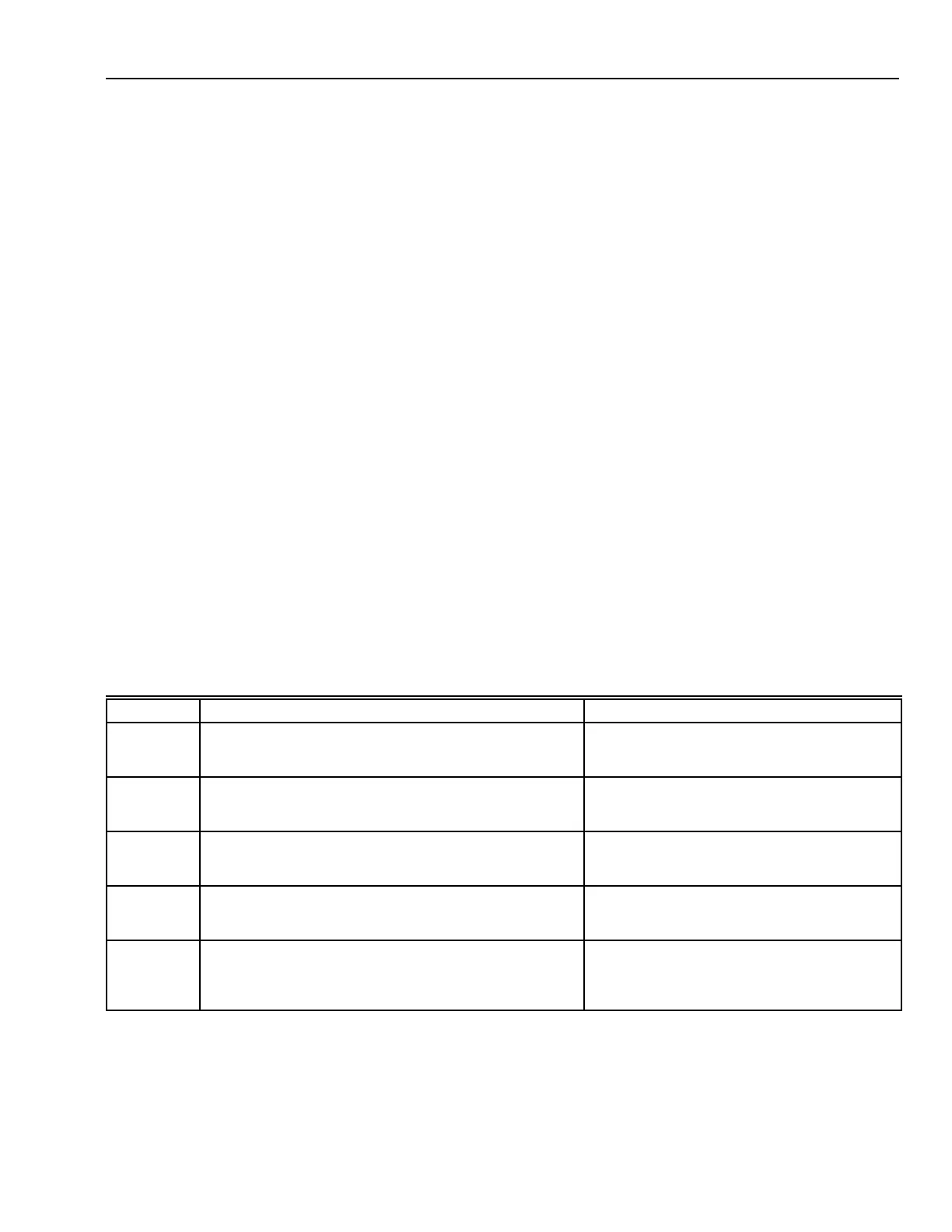

Table 23. Single-Phase Motor Characteristics and Applications.

Motor Type Characteristics Application

Universal

(Series)

Armature and field connected in series. Operates on dc or

ac with approximately the same speed and torque.

Where either ac or dc may be available. Used for

portable tools, vacuum cleaners, electric

typewriters, etc.

Split-Phase

Starting

Uses a pair of field windings for starting with one winding

slightly lagging. One winding is disconnected by a

centrifugal switch when running speed is reached.

Where starting torque and varying load are not

excessive. Used for oil burners, washing

machines, grinding wheels, etc.

Capacitor

Starting

Same as split-phase with a capacitor connected to the

winding that stays on line. Provides greater starting torque

with high efficiency and power factor.

Where high starting torque and heavy varying

loads exist. Used for air conditioners,

refrigerators, air compressors, etc.

Shaded-Pole

Starting

A short-circuited winding is used on each pole piece along

with a normal winding. Magnetic flux in the shorted turn

produces starting torque. Torque is low.

Where starting torque is low and less than 1/20

horsepower is required. Used for electric clocks.

Repulsion

Starting

Operates as a repulsion motor on starting and a centrifugal

switch converts it to an induction motor when running speed

is reached. Motor has a commutator as in a dc motor.

Provides high starting torque.

Where high starting torque is required. Used in

machine shops.

Loading...

Loading...