ENGINEERING MANUAL OF AUTOMATIC CONTROL

SMOKE MANAGEMENT FUNDAMENTALS

177

HVAC

HVAC systems can provide a means for smoke transport

even when the system is shut down (e.g., a bypass damper

venting smoke). Utilizing the HVAC system in smoke control

strategies can offer an economic means of control and even

meet the need for zone pressurization (e.g., pressurizing areas

adjacent to a fire compartment).

CONTROL OF SMOKE

Smoke control uses barriers within the building along with

airflow produced by mechanical fans to contain the smoke. For

some areas, the pressure difference across the barrier can be

used to control the smoke. Where the barriers have large

penetrations, such as door openings, it is easier to design and

measure the control system results by using airflow methods.

Both methods, pressurization and airflow, are discussed in the

following paragraphs.

In addition to life safety requirements, smoke control systems

should be designed to provide a path to exhaust the smoke to

the outdoors, thereby relieving the building of some of the heat

of the fire and the pressure of the gas expansion.

PRESSURIZATION

Pressurization of nonsmoke areas can be used to contain

smoke in a fire or smoke zone. Barriers are required between

the nonsmoke areas and the area(s) containing the smoke and

fire. For the barrier to perform correctly in a smoke control

system, a static pressure difference is required across any

penetrations or cracks to prevent the movement of smoke.

Figure 3 illustrates such an arrangement with a door in a wall.

The high pressure side can act as a refuge or an escape route,

the low pressure side as a containment area. The high pressure

prevents any of the smoke from infiltrating into the high

pressure area.

LOW PRESURE

SIDE

HIGH PRESURE

SIDE

M13023

SMOKE

control system should be able to maintain these minimum

pressure differences while the building is under typical

conditions of stack effect and wind. This table is for gas

temperatures of 1700F adjacent to the barrier. To calculate

pressure differences for gas temperatures other than 1700F, refer

to data in NFPA 92A.

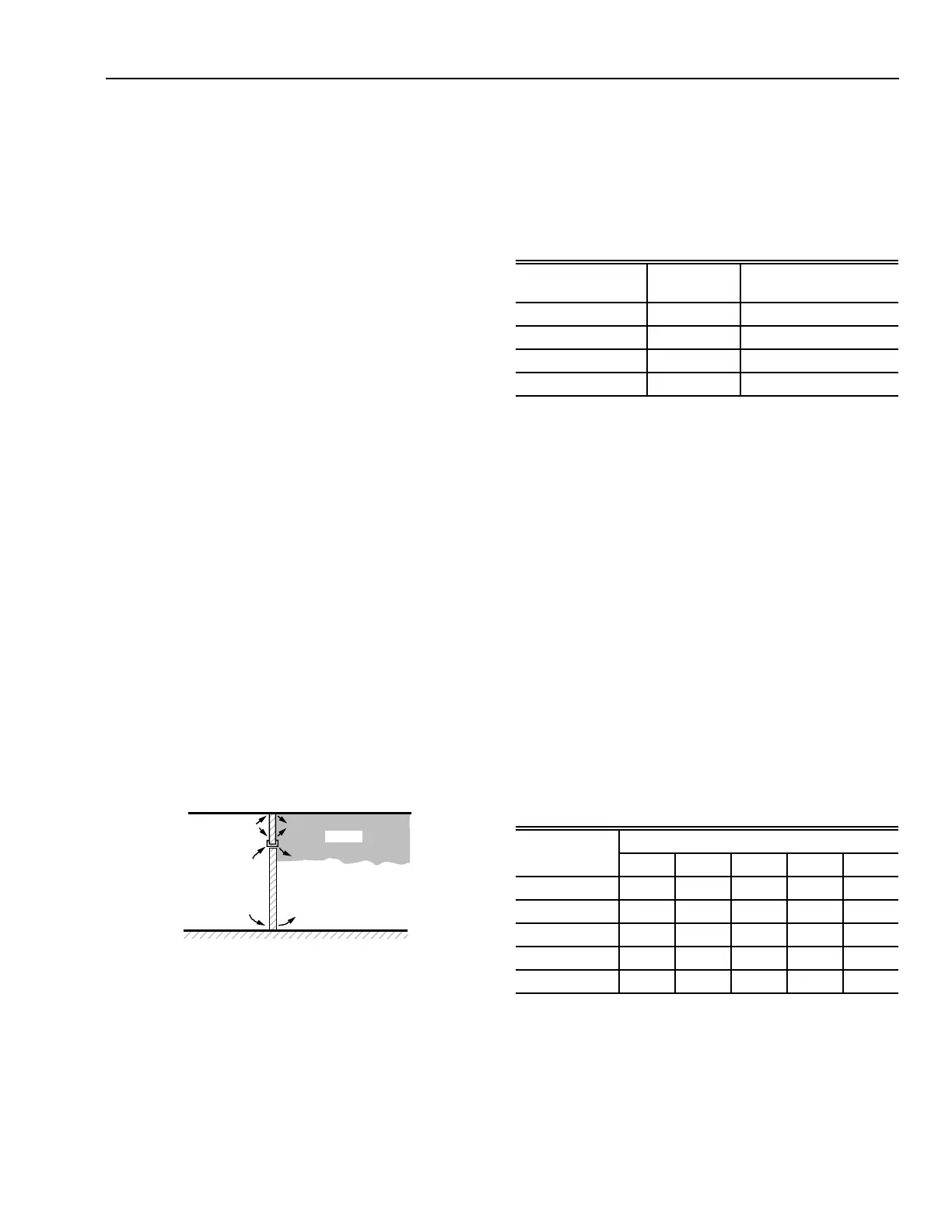

Table 1. Suggested Minimum Design Pressure

Differences Across Smoke Barriers.

Fig. 3. Pressurization Used to Prevent Smoke Infiltration.

Guidelines for pressurization values are found in NFPA 92A,

Recommended Practice for Smoke Control Systems. Table 1

indicates minimum design pressure differences across smoke

barriers. The design pressure difference listed is the pressure

difference between the smoke zone and adjacent spaces while

the affected areas are in the smoke control mode. The smoke

Pressure differences can vary because of fan pulsations, wind,

and doors opening and closing. Short-term variances, from the

suggested minimum design pressure differences in Table 1, do

not seem to have significant effects on the protection furnished

by a smoke control system. There is no actual definitive value

for short-term variances. The value depends on the tightness of

the construction and the doors, the toxicity of the smoke, the

airflow rates, and the volume of the protected space. Occasional

variances of up to 50 percent of the maximum design pressure

difference can be allowed in most cases.

Table 2 lists values for the maximum pressure differences

across doors. These values should not be exceeded so that the

doors can be used when the pressurization system is in

operation. Many door closers require less force when the door

is initially opened than the force required to open the door fully.

The sum of the door closer force and the pressure imposed on

the door by the pressurization system combine only until the

door is opened sufficiently to allow air to move easily through

the door. The force imposed by a door closing device on closing

a door is often different from that imposed on opening a door.

Table 2. Maximum Pressure Difference Across Doors

in in. wc (NFPA 92/92A).

Building Type

Ceiling

Height (ft)

Design Pressure

Difference (in. wc)

Sprinklered Unlimited 0.05

Nonsprinklered 9 0.10

Nonsprinklered 15 0.14

Nonsprinklered 21 0.18

Door Closer

Door Width (in.)

Force (lb ft)

32 36 40 44 48

6 0.45 0.40 0.37 0.34 0.31

8 0.41 0.37 0.34 0.31 0.28

10 0.37 0.34 0.30 0.28 0.26

12 0.34 0.30 0.27 0.25 0.23

14 0.30 0.27 0.24 0.22 0.21

NOTE: Total door opening force is 30 lb ft. Door height

is 7 ft. The distance from the doorknob to the

knob side of the door is 3 in. (ADA has

requirements which conflict with this table.)

Loading...

Loading...