ENGINEERING MANUAL OF AUTOMATIC CONTROL

DAMPER SELECTION AND SIZING

459

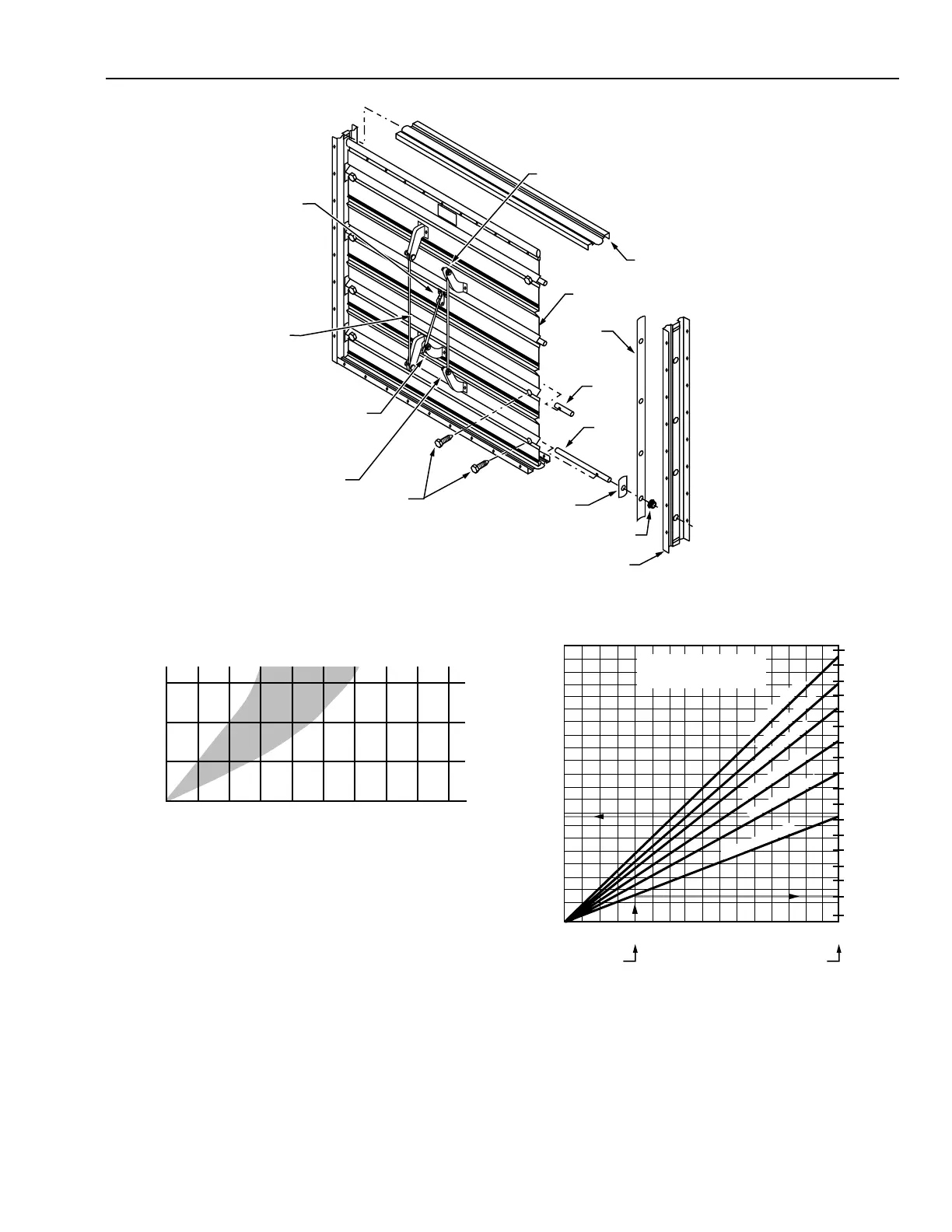

Fig. 17. Typical (Opposed Blade) Damper Construction.

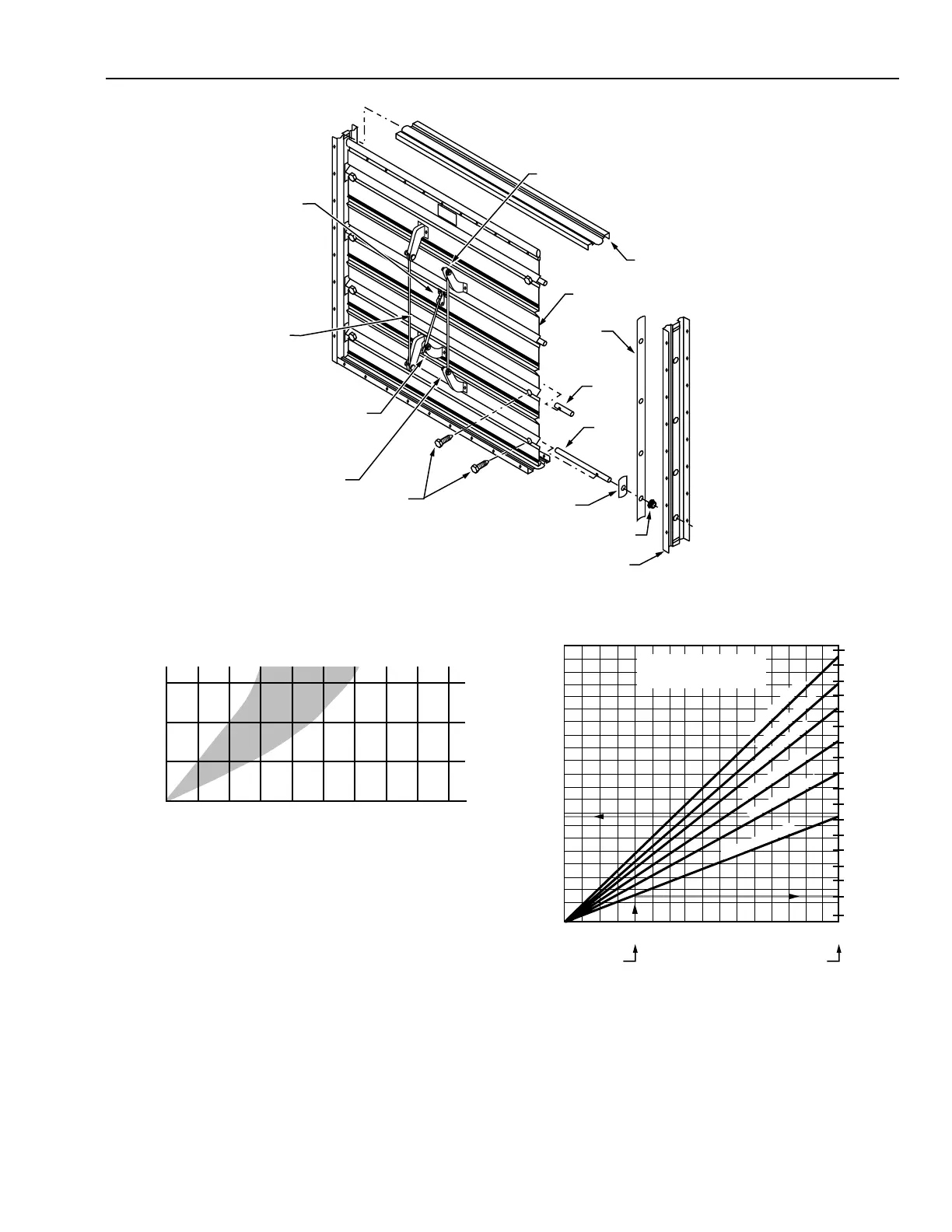

Fig. 18. Graphic Presentation of Leakage Performance.

0102030405060708090

3.0

2.0

1.0

0

STATIC PRESSURE ACROSS

DAMPER (IN. WC)

LEAKAGE IN CFM PER FT

2

OF DAMPER AREA (FT

3

/MIN)

LEAKAGE OF A SPECIFIC DAMPER DEPENDS UPON THE HEIGHT AND

WIDTH RELATIONSHIP AS WELL AS THE AREA. THE SHADED AREA

SHOWS THE RANGE OF LEAKAGE FOR A GIVEN AREA.

NOTE:

TORQUE APPLIED TO DAMPER = 5 LB-IN. PER FT

2

OF DAMPER AREA

C2391

110

100

90

80

70

60

50

40

30

20

10

0

061218 24 30 36 42 48

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

A-DIMENSION LEAKAGE SCFM

B-DIMENSION LEAKAGE SCFM

A DIMENSION B DIMENSION

LEAKAGE VS DAMPER SIZE

APPLIED TORQUE 50 LB-IN.

ACTUAL TEST DATA

1 IN. WC STATIC

2 IN. WC STATIC

3 IN. WC STATIC

4

IN

. W

C

S

T

A

T

IC

5 IN. WC STATIC

6 IN. WC STATIC

TOTAL LEAKAGE =

B-DIMENSION LEAKAGE + A-DIMENSION LEAKAGE

WHERE:

A-DIMENSION = OUTSIDE DIMENSION PARALLEL TO

THE DAMPER BLADES

B-DIMENSION = OUTSIDE DIMENSION PERPENDICULAR

TO THE DAMPER BLADES

M10419

DAMPER SIZE IN INCHES

Fig. 19. Low Leakage Dampers.

LINKAGE

ARM

LINKAGE

ROD

DUAL

LINKAGE ARM

LINKAGE ARM

AXLE SCREWS

THRUST

WASHER

DRIVE

AXLE

BLADE

AXLE

TRUNION

BEARING

DAMPER BLADE

HORIZONTAL

FRAME MEMBER

M10436

AXLE BEARING

VERTICAL

FRAME MEMBER

SIDE

SEAL

Loading...

Loading...