MICROPROCESSOR-BASED/DDC FUNDAMENTALS

146

ENGINEERING MANUAL OF AUTOMATIC CONTROL

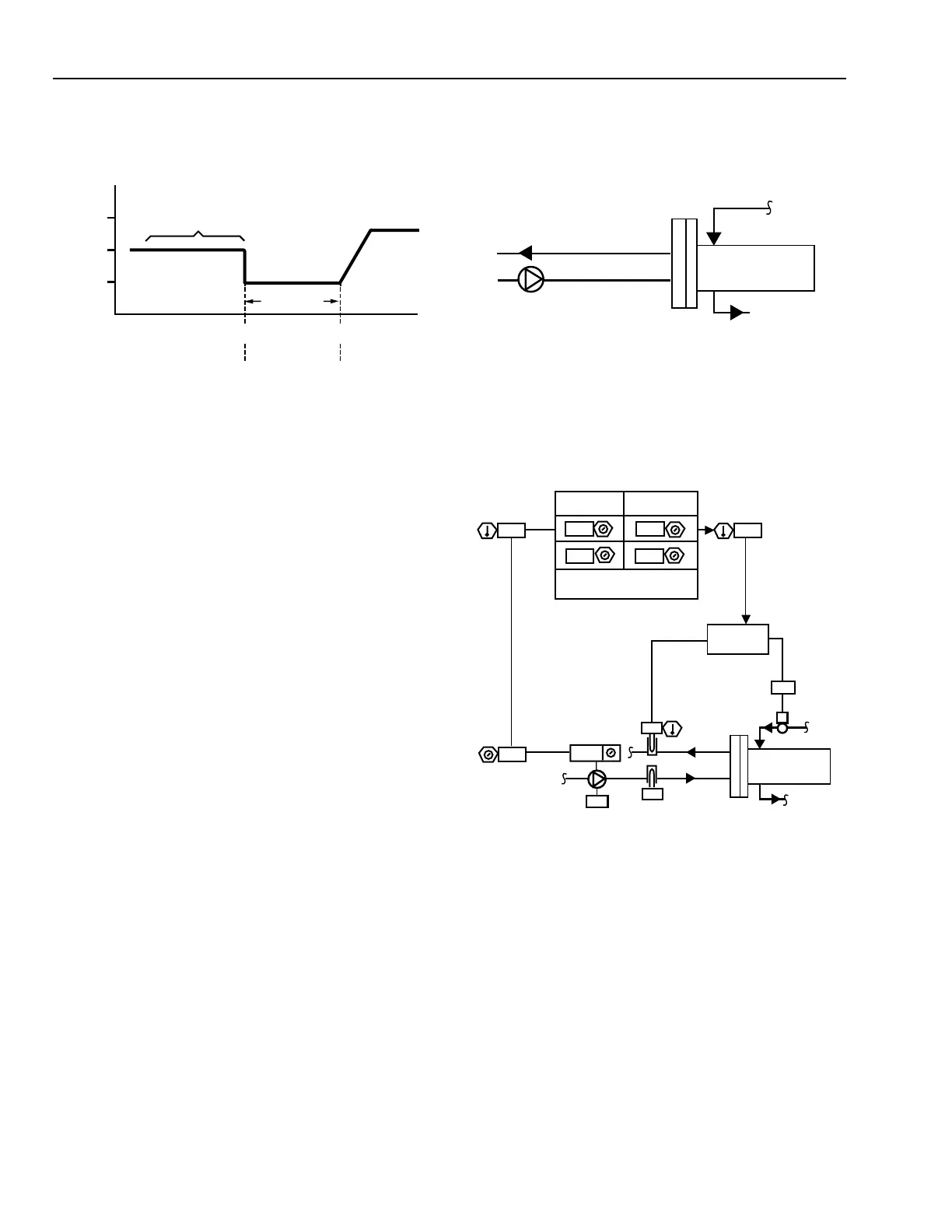

staged by a PI algorithm with software heat anticipation. See

Figure 15. During reheat, the control mode changes to constant

volume, variable discharge temperature.

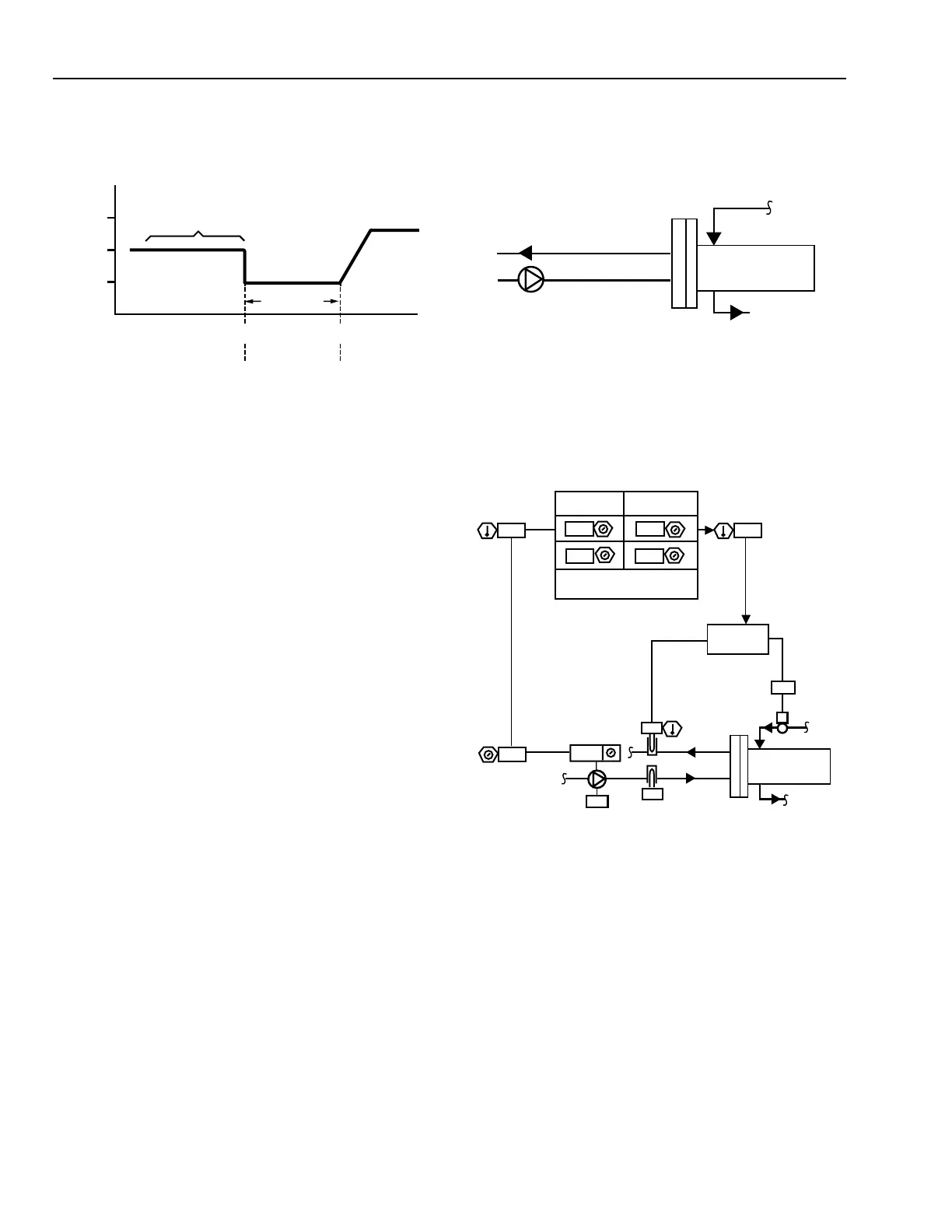

An example of this approach follows for control of a hot

water converter:

Step 1—Develop flow schematic of the process to be controlled

(Fig. 16).

M15035

STEAM TO

HOT WATER

CONVERTER

HOT WATER RETURN

HOT WATER SUPPLY

STEAM

M15036A

STEAM TO

HOT WATER

CONVERTER

STEAM

VALVE

140

ON

HOT

WATER

RETURN

PUMP-ON

SETPOINT

AUTO

52

152

58

PERCENT

OPEN

IN OUT

SP

PID

22 152

HOT WATER

PUMP

OUTSIDE

AIR

SETPOINT

OUTSIDE

AIR

HOT WATER

SETPOINT

0

120

60

170

HOT WATER RESET

SCHEDULE

Fig. 15. Control Sequence for VAV Cooling with

Sequenced Electric Reheat.

SYSTEM-LEVEL CONTROLLER

System-level controllers are variable-function devices

applied to a wide variety of mechanical systems. These

controllers can accommodate multiloop custom control

sequences and have control integrated with energy management

and building management functions. The examples that follow

cover direct digital control functions for a system-level

controller. Integrated building management functions are

covered in the Building Management System Fundamentals

section.

Where the examples indicate that user entered values are

furnished (e.g., setpoint), or that key parameters or DDC

operator outputs will have display capability, this represents

sound software design practice and applies whether or not the

controller is tied into a central building management system.

Data is entered or displayed in non-BMS applications by a

portable operator’s terminal or by a keypad when display is

integral with the controller.

A five-step approach can be used to define DDC programs.

1. Develop a system flow schematic as a visual representa-

tion of the process to be controlled. The schematic may

be provided as a part of the plans and specifications for

the job. If not, a schematic must be created for the sys-

tem.

2. Add actuators, valves, sensors, setpoints, and operational

data required for control and operation.

3. Write a detailed sequence of operation describing the

relationship between inputs, outputs, and operational

data points.

4. Develop a detailed flowchart of the control sequence

using either DDC operators or a programming logic flow

diagram. Programs written totally in a high-level

language use the logic flow diagram.

5. Write the program using either DDC operators (Table

1) or high-level language statements.

Fig. 17. Schematic Illustrating Sensors, Actuators, and

Operational Data for Steam to Hot Water Converter.

If the DDC system is provided with a BMS having a color

monitor, a graphic may be required to be displayed with live,

displayable and commandable points (12 total). If a BMS is

not provided, the points may be required to be displayed on a

text terminal (fixed or portable) at the system level controller.

Fig. 16. Schematic of Steam to Hot Water Converter.

Step 2—Identify required sensors, actuators, and operational

data (Fig. 17). Refer to the Chiller, Boiler, and

Distribution System Control Applications section for a

symbol legend.

MAX

FLOW

REHEAT

FLOW

MIN

FLOW

COLD HOT

CONSTANT VOLUME,

VARIABLE DISCHARGE TEMPERATURE

CONSTANT

DISCHARGE

TEMPERATURE,

VARIABLE

VOLUME

C2686

COOLING

SETPOINT

HEATING

SETPOINT

SPACE LOAD

PRIMARY AIRFLOW (CFM)

DEAD BAND

Loading...

Loading...