ENGINEERING CMANUAL OF AUTOMATION CONTROL

AIR HANDLING SYSTEM CONTROL APPLICATIONS

220

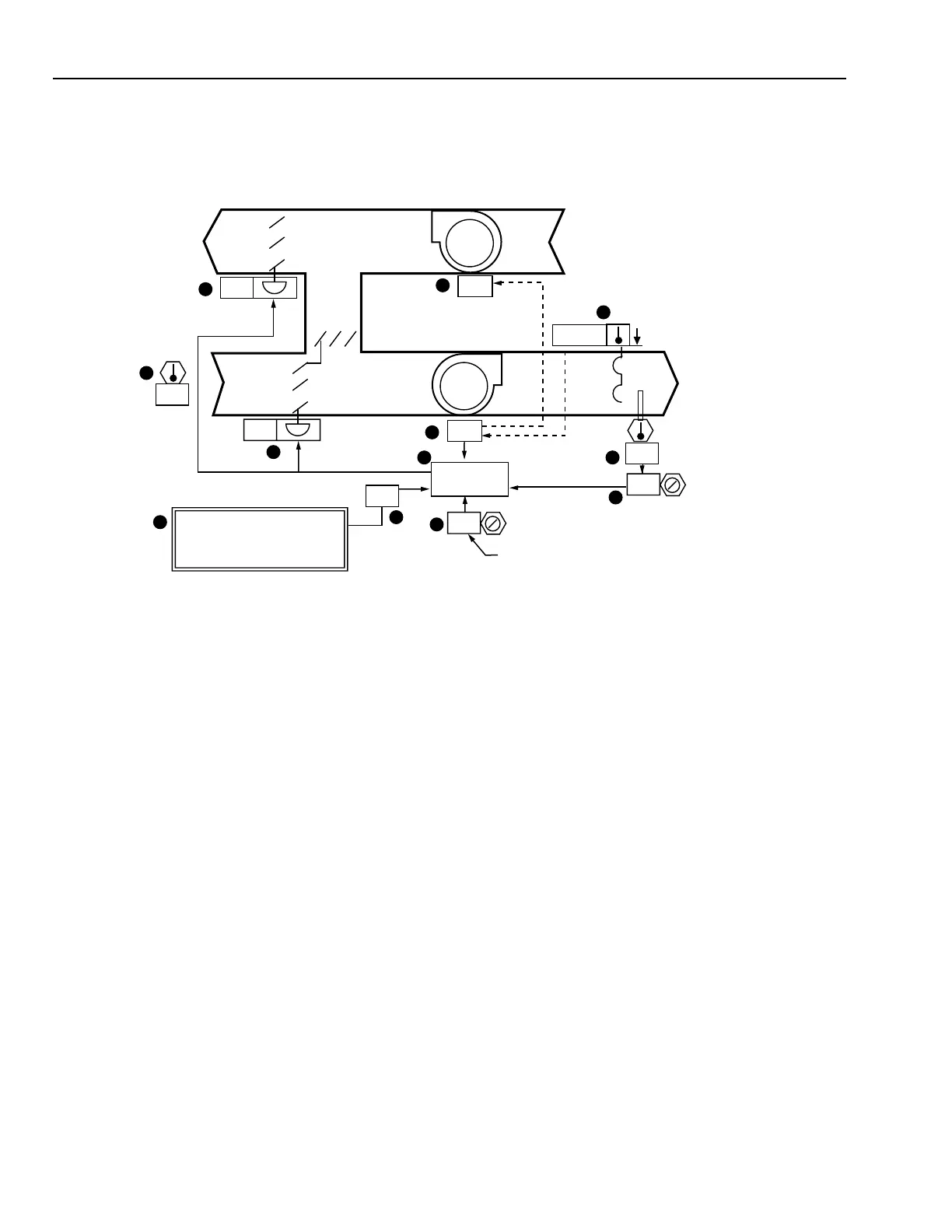

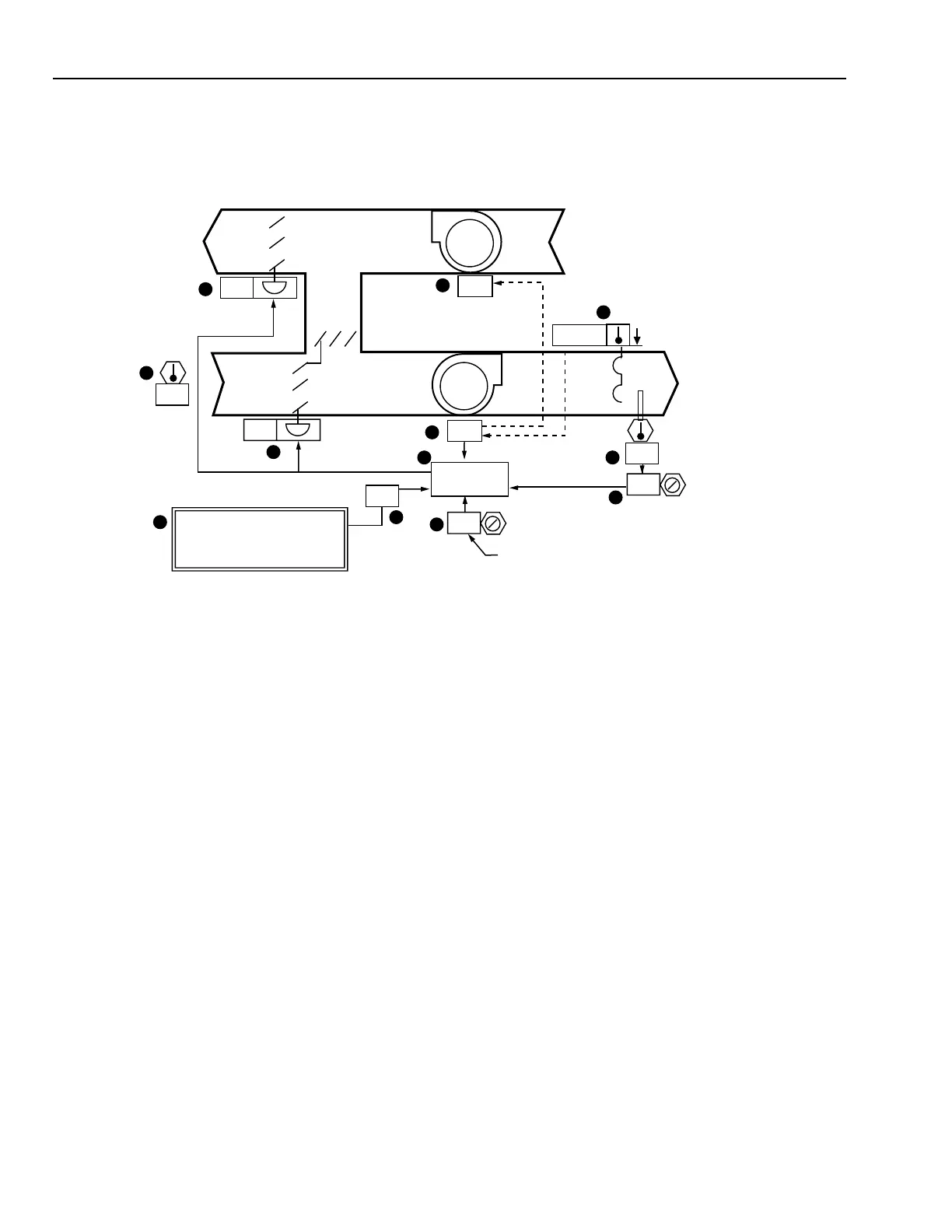

MIXED AIR CONTROL WITH ECONOMIZER CYCLE (VENTILATION SYSTEM ONLY)

Functional Description

OA

22

ON

ECONOMIZER DECISION.

REFER TO PREVIOUS

ECONOMIZER OPTIONS

OA MINIMUM SETPOINT

(NOTE: THE TEST AND BALANCE INITIAL

VALUE FOR PROPER VENTILATION IS 22)

M10453

10

12

11

8

CONTROL

PROGRAM

49

83

EA

MA

RA

ON

ON

55

9

5

1

4

2

3

7

6

83

55

NORMAL

PERCENT

OPEN

NC

NO

NC

Item

No. Function

1-3 Control system energizes when fan is turned

on (See FAN SYSTEM START-STOP

CONTROL).

4 MA temperature maintained by modulating

mixing dampers.

5,6 OA and EA dampers close and RA damper

opens when fan is off and modulate for

temperature control when fan is on.

7 Setpoint for MA temperature control.

8 Setpoint value for minimum ventilation

damper position.

9 Determines when OA is suitable to assist in

cooling.

10 Control program coordinates MA, minimum

ventilation, and economizer control of mixing

dampers.

FEATURES

1. The proper proportions of OA and RA are admitted to

maintain the desired MA temperature during economizer

operation periods.

2. A minimum quantity of OA, determined by the software

adjustable setpoint value, is assured at all times.

3. The OA economizer changeover program returns the OA

damper to the minimum position when OA is not suitable.

CONDITIONS FOR SUCCESSFUL OPERATION

1. Adequate mixing of OA and RA. Mixing may be obtained

using a special mixing chamber. The temperature sensor

should be in the fan discharge when possible. The fan in

a blow-through system usually provides adequate mixing.

2. An MA averaging element sensor is used on draw-through

units.

LIMITATIONS

If the manual positioning value is set to admit a large quantity

of OA and the OA temperature falls below the temperature at

which only minimum OA is required for MA temperature

control, a source of heat is necessary to maintain the MA

temperature.

Loading...

Loading...