ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

387

Functional principles:

The primary side consists of the supply and return lines, plus

necessary pressure reducing, regulating, and safety equipment.

This is self-regulating equipment which provides a given

differential pressure, absolute pressure reducing, and safety

close off functions.

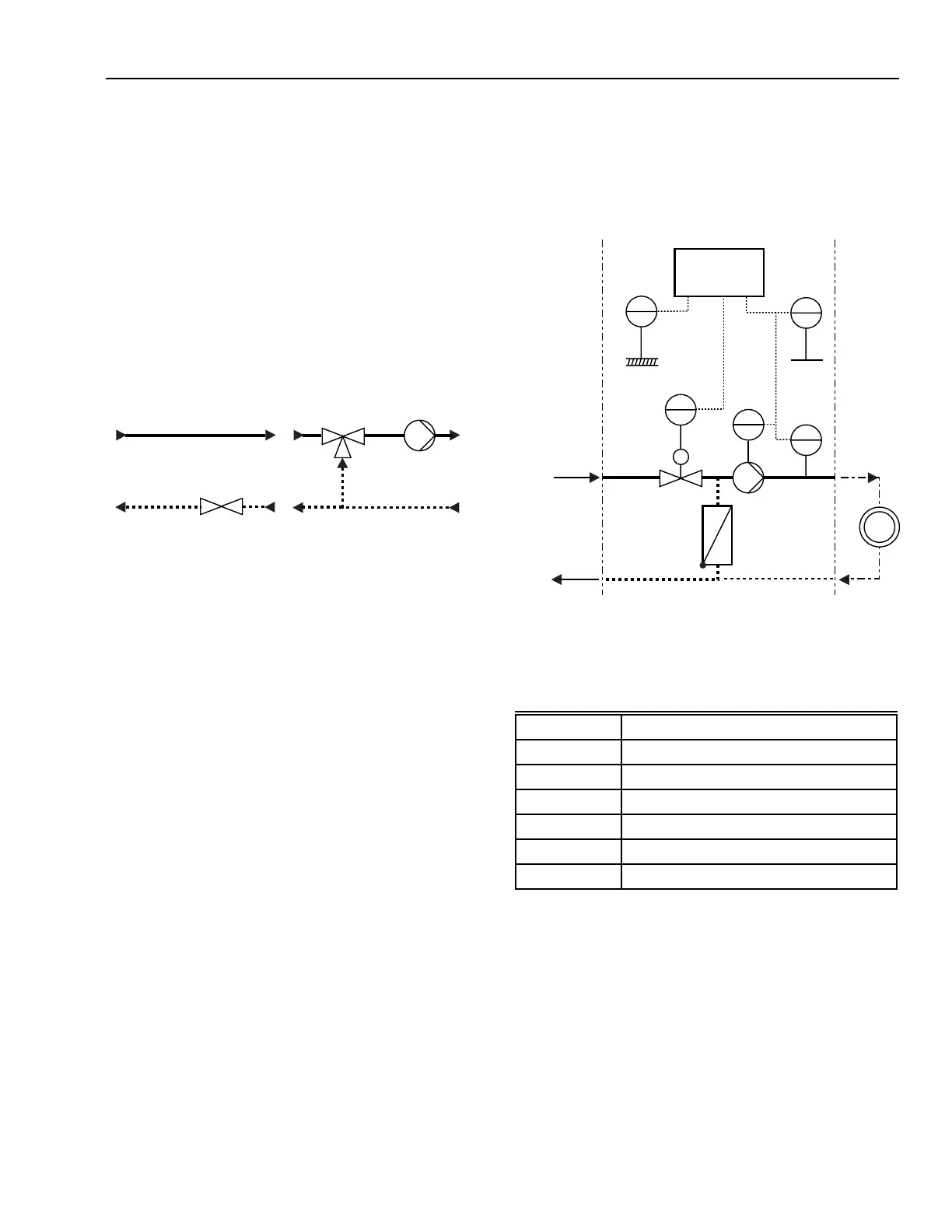

The heat regulation unit (Fig. 130) provides the required

temperature by controlling the primary flow (A) or by mixing

the cooled return water with supply water (B). Different

configurations with two and three way valves can be used. In

the flow control configuration a fixed speed circulating pump

increases the pressure in the return line above the supply flow

pressure. In the temperature control configuration either a jet

pump or a three way valve is used.

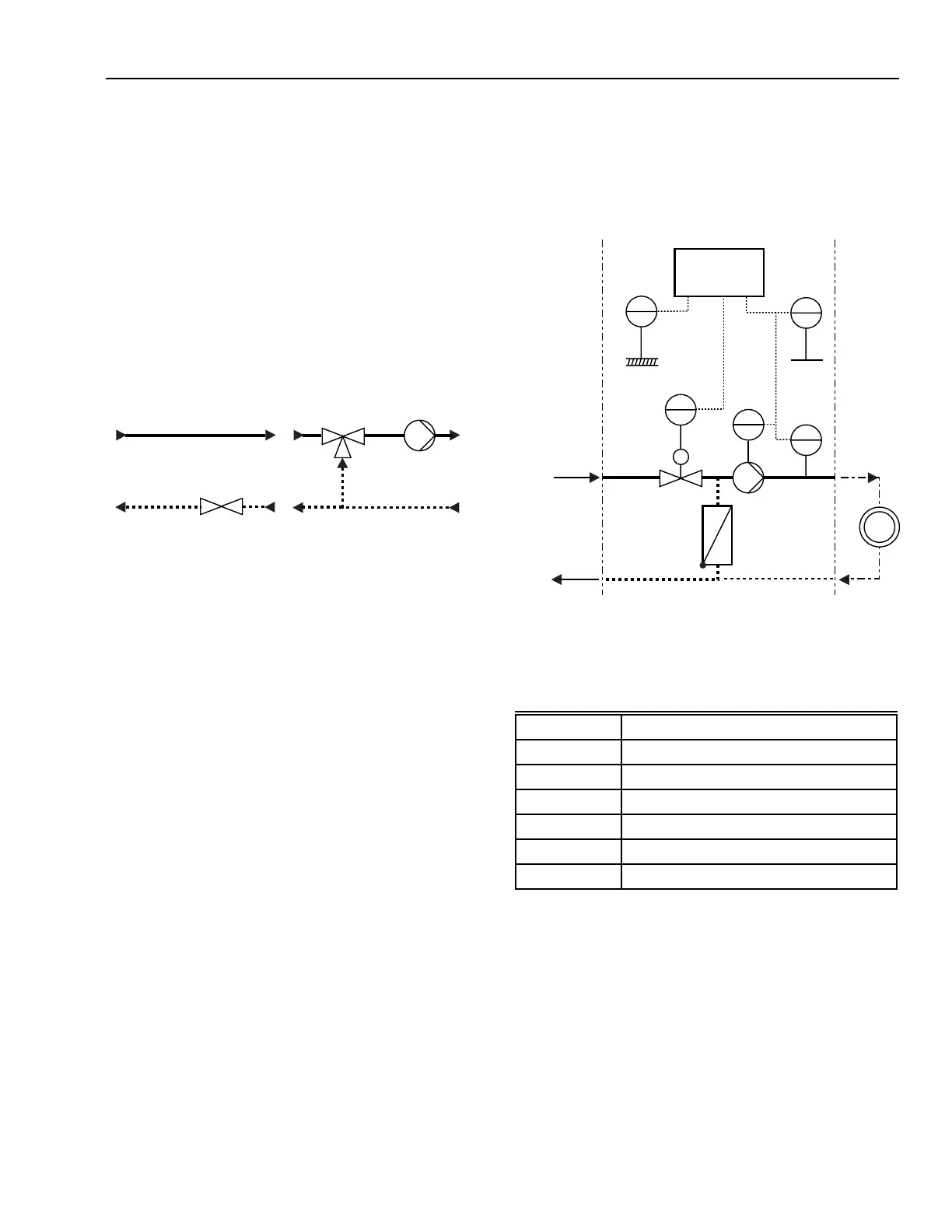

Fig. 131. Small Direct Heat Transfer

Substation for Multiple Family Buildings

Table 9. Description of Figure 131 Reference Points.

Fig. 130. Two- And Three-Way Valve Configurations for a

Heat regulation Unit.

Jet pumps use the effect of injection, making a mechanical

pump unnecessary, thereby, saving electrical energy. However,

adapting and dimensioning jet pump applications to fit operating

conditions is difficult.

Control loops used in a direct substation:

– Supply flow temperature reset on outdoor air temperature.

– Return temperature limit.

–Time schedule functions.

–Night setback and frost protection.

M11446

CONTROL VALVE

CIRCULATING

PUMP

THREE-WAY

MIXING VALVE

OR JET PUMP

A) FLOW CONTROL

B) TEMPERATURE CONTROL

SUPPLY LINE

RETURN LINE

Y

11

M

TC

TI

01

OUTSIDE AIR

TI

31

TIC

13

Y

12

ROOM

CONSUMER

SSF

SRF

PSF

PRF

DISTRIBUTION

M11435

SUBSTATION

Small Substation For Multiple Family Buildings

Figure 131 shows a typical direct heat transfer substation.

Reference Description

TC Controller

TI 01 Outdoor air temperature sensor

TI 31 Room temperature

TIC 13 SSF temperature

Y 11 Actuator control valve PSF

Y 12 Circulating pump

Loading...

Loading...