PNEUMATIC CONTROL FUNDAMENTALS

67

ENGINEERING MANUAL OF AUTOMATIC CONTROL

CONDENSING DRYING

The two methods of condensing drying are high-pressure

drying and refrigerant drying.

High-Pressure Drying

High-pressure drying may be used when main air piping is

kept away from outside walls and chilling equipment. During

compression and cooling to ambient temperatures, air gives

up moisture which then collects in the bottom of the storage

tank. The higher the tank pressure, the greater the amount of

moisture that condenses. Maintaining a high pressure removes

the maximum amount of moisture. The compressor should have

a higher operating pressure than is required for air supply

purposes only. However, higher air pressure requires more

energy to run the compressor. The tank must include a manual

drain valve or an automatic trap to continually drain off

accumulated moisture. With tank pressures of 70 to 90 psi, a

dew point of approximately 70F at 20 psi can be obtained.

Refrigerant Drying

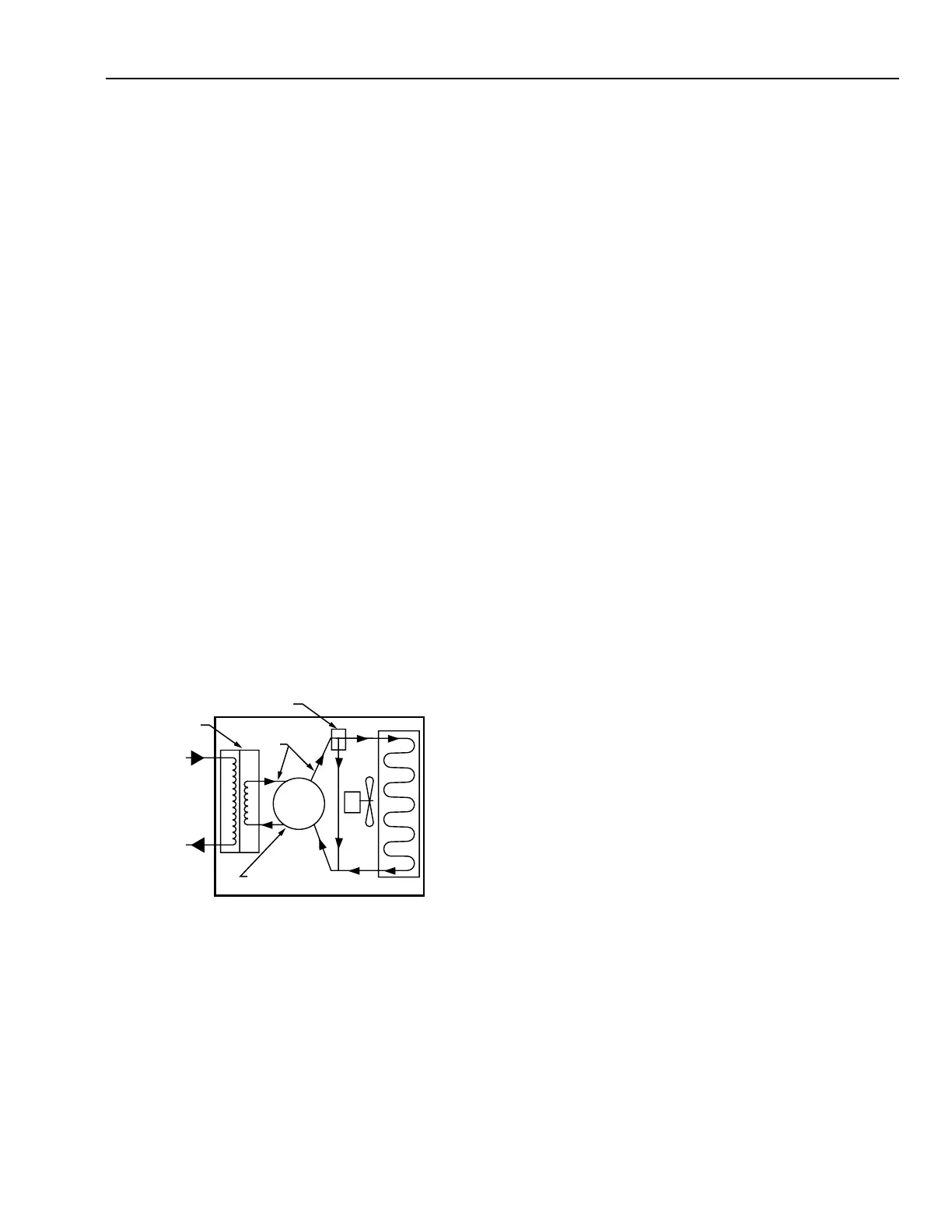

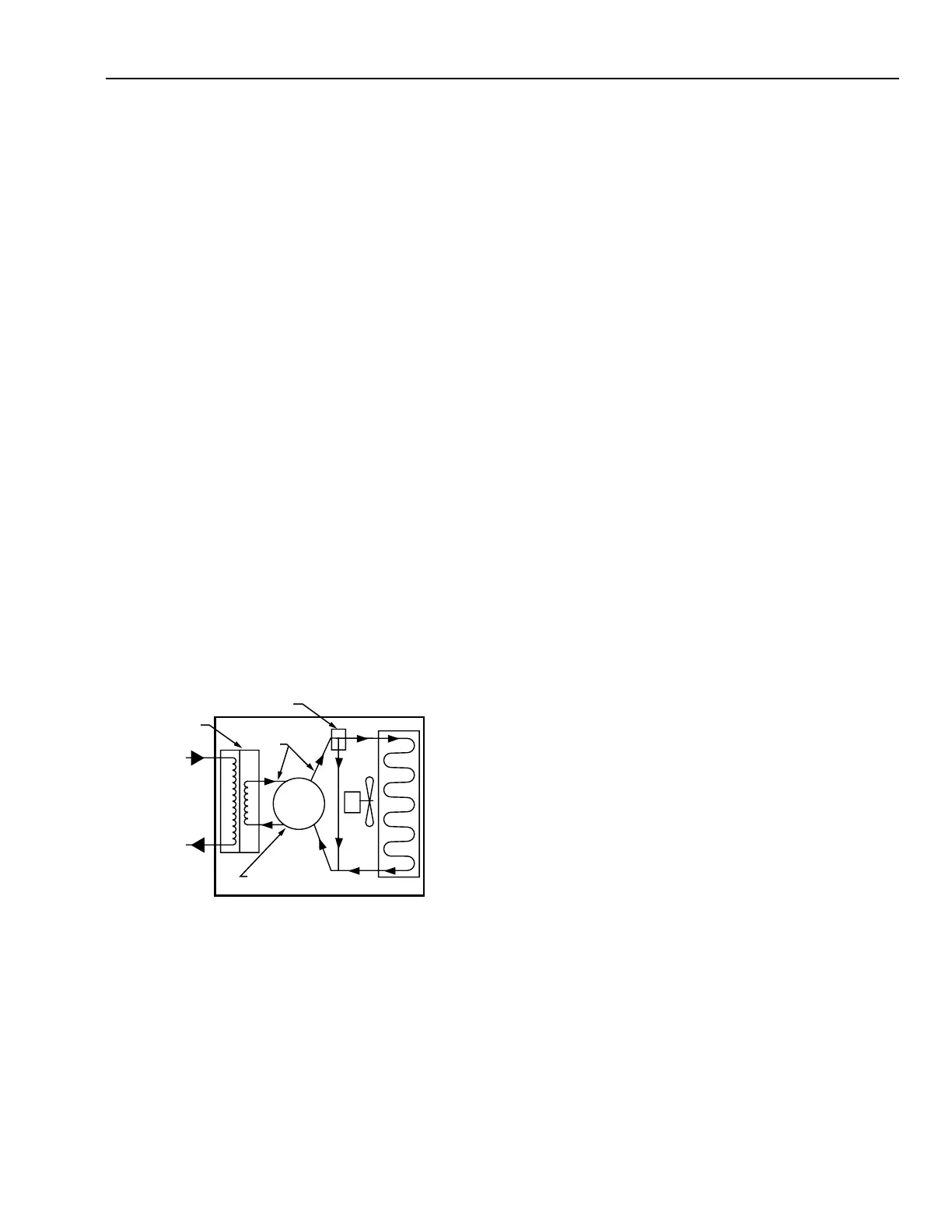

Lowering air temperature reduces the ability of air to hold

water. The refrigerated dryer (Fig. 14) is the most common

means of obtaining dry, compressed air and is available in

several capacities. It provides the greatest system reliability

and requires minimal maintenance.

The heat exchanger reduces the temperature of the com-

pressed air passing through it. A separator/filter condenses

both water and oil from the air and ejects the condensate

through a drain. A temperature-sensing element controls the

operation of the refrigeration system to maintain the tempera-

ture in the exchanger.

With a dew point of 35F and an average compressor tank

pressure of 80 psi, air is dried to a dew point of 12F at 20 psi.

Under severe winter conditions and where piping and devices

are exposed to outside temperatures, the 12F dew point may

not be low enough.

DESICCANT DRYING

A desiccant is a chemical that removes moisture from air. A

desiccant dryer is installed between the compressor and the

PRV. Dew points below –100F are possible with a desiccant

dryer. The desiccant requires about one-third of the process

air to regenerate itself, or it may be heated. To regenerate,

desiccant dryers may require a larger compressor to produce

the needed airflow to supply the control system and the dryer.

It may be necessary to install a desiccant dryer after the

refrigerant dryer in applications where the 12F dew point at

20 psi mainline pressure does not prevent condensation in air

lines (e.g., a roof-top unit exposed to severe winters).

The desiccant dryer most applicable to control systems uses

the adsorbent principle of operation in which porous materials

attract water vapor. The water vapor is condensed and held as

a liquid in the pores of the material. The drying action continues

until the desiccant is saturated. The desiccant is regenerated

by removing the moisture from the pores of the desiccant

material. The most common adsorbent desiccant material is

silica gel, which adsorbs over 40 percent of its own weight in

water and is totally inert. Another type of adsorbent desiccant

is the molecular sieve.

A desiccant is regenerated either by heating the desiccant

material and removing the resulting water vapor from the

desiccant chamber or by flushing the desiccant chamber with

air at a lower vapor pressure for heatless regeneration. To

provide a continuous supply of dry air, a desiccant dryer has

two desiccant chambers (Fig. 15). While one chamber is being

regenerated, the other supplies dry air to the system. The

cycling is accomplished by two solenoid valves and an electric

timer. During one cycle, air passes from the compressor into

the left desiccant chamber (A). The air is dried, passes through

the check valve (B), and flows out to the PRV in the control

system.

HOT GAS

BYPASS

CONTROL

HEAT

EXCHANGER

AIR IN

AIR OUT

REFRIGERANT

LINES

REFRIGERATION

UNIT

CONDENSOR

REFRIGERANT DRYER

C1888

Fig. 14. Typical Refrigerant Dryer Airflow Diagram.

The refrigerant dryer uses a non cycling operation with a

hot gas bypass control on the refrigerant flow to provide a

constant dew point of approximately 35F at the tank pressure.

The refrigeration circuit is hermetically sealed to prevent loss

of refrigerant and lubricant and to protect against dirt.

Loading...

Loading...