Monitoring and Operating the Controller

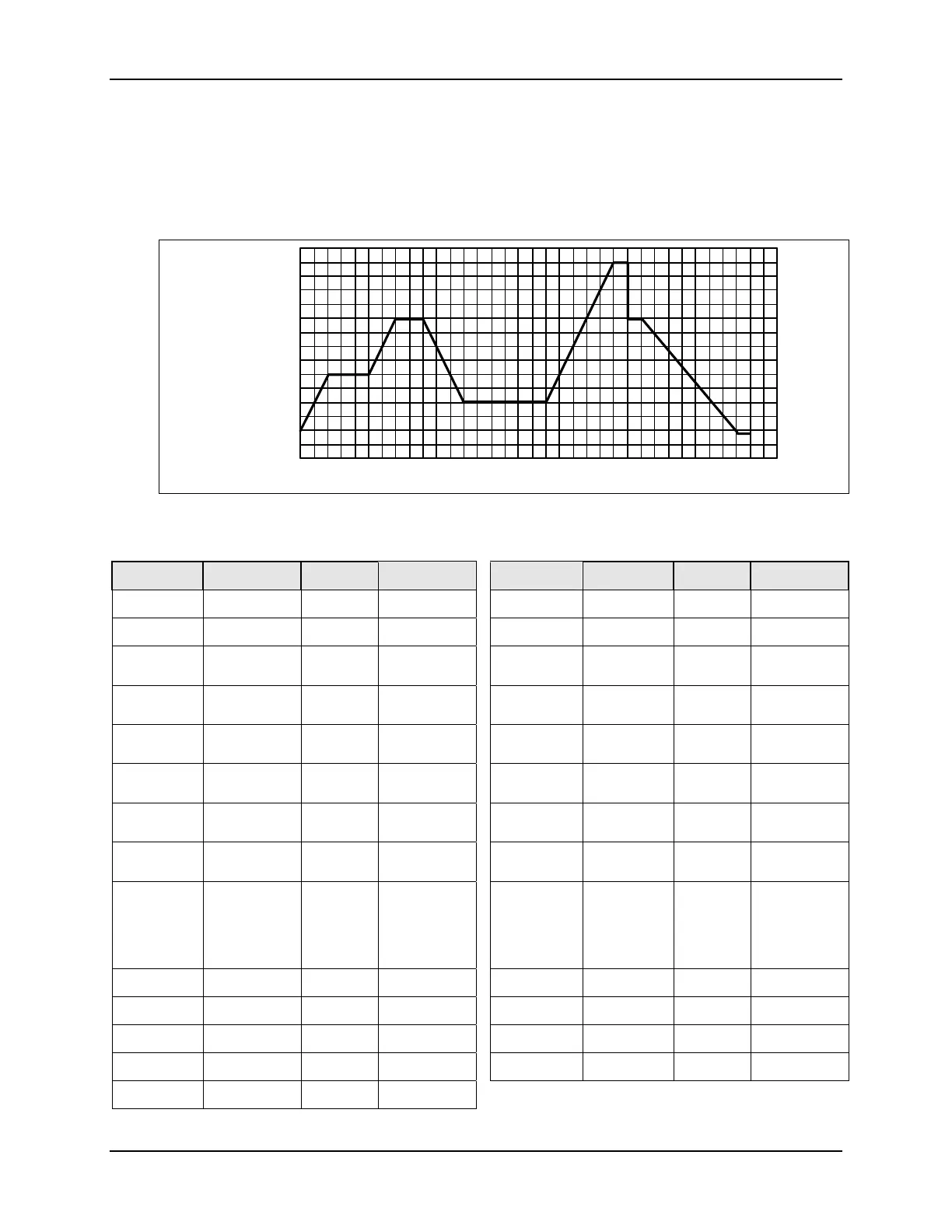

Ramp/soak profile example

Before you perform the actual configuration, we recommend that you draw a Ramp/Soak

profile in the space provided on the “Program Record Sheet” (Figure 4-4) and fill in the

associated information. An example of a Ramp-Soak Profile is shown in Figure 4-3.

Start setpoint is at 200 degrees F.

500

400

200

300

°

F

Time/Hours

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

SEG 2

SEG 3

SEG 4

SEG 5

SEG 6

SEG 7

SEG 8

SEG 9

SG 10

SG 11

SG 12

SEG 1

F

20765

Setpoint

Figure 4-3 Ramp/Soak Profile Example

Ramp/Soak Profile Example

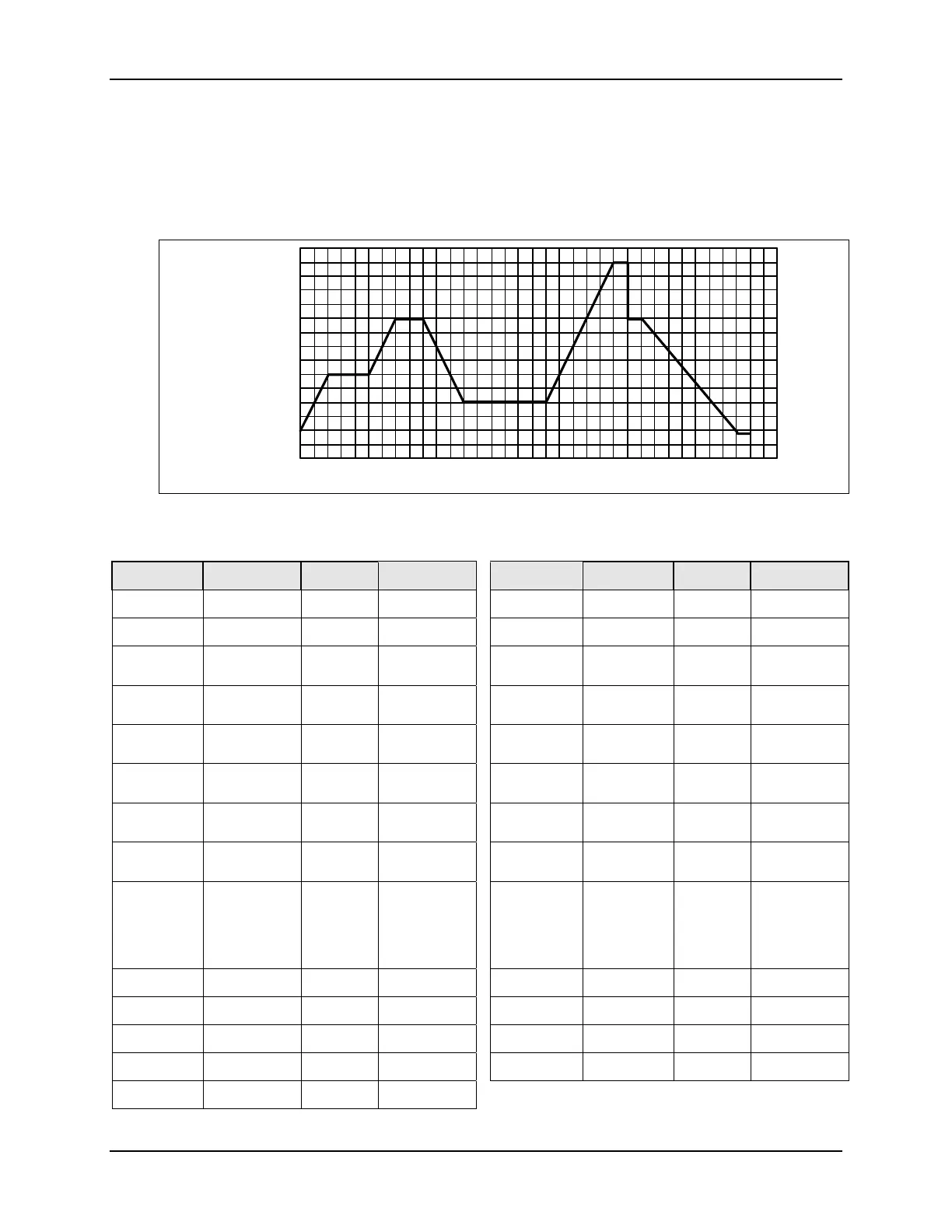

Prompt Function Segment Value Prompt Function Segment Value

STRT SEG

Start Seg. 1

SEG4TIME

Soak Time 4 1 hr.

END SEG

End Seg. 12

SEG5RAMP

Ramp Time 5 1 hr:30 min.

RAMP UNIT

Engr. Unit for

Ramp

TIME

SEG6 SP

Soak SP 6 250

RECYCLES

Number of

Recycles

2

SEG6TIME

Soak Time 6 3 hr:0 min.

SOAK DEV

Deviation

Value

0

SEG7RAMP

Ramp Time 7 2 hr:30 min.

PROG END

Controller

Status

LAST SP

SEG8 SP

Soak SP 8 500

STATE

Controller

State at end

HOLD

SEG8TIME

Soak Time 8 0 hr:30 min.

KEYRESET

Reset SP

Program

DISABLE

SEG9RAMP

Ramp Time 9 0

HOTSTART

PV Hot Start

Program

Initialization

or power up

in SPP

DISABLE

SG10 SP

Soak SP 10 400

SEG1RAMP

Ramp Time 1 1 hr.

SG10 TIME

Soak Time 10 0 hr:30 min.

SEG2 SP

Soak SP 2 300

SG11RAMP

Ramp Time 11 3 hr:30 min.

SEG2TIME

Soak Time 2 1 hr:30 min.

SG12 SP

Soak SP 12 200

SEG3RAMP

Ramp Time 3 1 hr.

SG12TIME

Soak Time 12 0 hr:30 min.

SEG4 SP

Soak SP 4 400

128 UDC3200 Universal Digital Controller Product Manual 12/04

Loading...

Loading...