Relevant modes:

(1) Linear speed input module: It has two functions: calculating the synchronous frequency in torque

control according to the linear speed and calculating the roll diameter according to the linear speed.

(2) Tension setting module: Used to set the tension adapting to the control system. It needs to be

adjusted according to the actual situation. After confirmation, the value remains the same. In some

scenarios where the forming effect after winding needs to be improved, the tension taper function can

be used so that the tension decreases as the roll diamter increases.

(3) Real-time roll diameter calculation module: The calculation accuracy of roll diameter determines

the control performance. The roll diameter can be calculated according to the inverter output

frequency and the linear speed. In addition, it can also be calculated through the thickness or sensor.

The linear speed is widely used for the calculation. If the set linear speed is used for the calculation,

you you choose whether to enable the function of roll diameter change limiting.

(4) Torque compensation module: Torque compensation includes friction torque compensation and

inertia torque compensation. Friction torque compensation is used to eliminate the impact of friction

on tension, and it needs to be adjusted according to actual requirements. rRotation inertia includes

inertial of mechanical systems and that of materials. To keep the tension stable in ACC/DEC,

compensation torque is required. In some cases, without strict tension control requirements, disabling

rotation inertia torque compensation can also achieve the control.

(5) Material feeding interrupt detection and processing module: The function is valid when material

feeding interrupt detection has been enabled.

(6) This function is applied to automatic reel change. After the inverter is started if the pre-drive

function terminal is valid, the roller runs at the set linear speed. When the terminal is invalid, the

inverter will automatically switch to the corresponding control mode after a period.

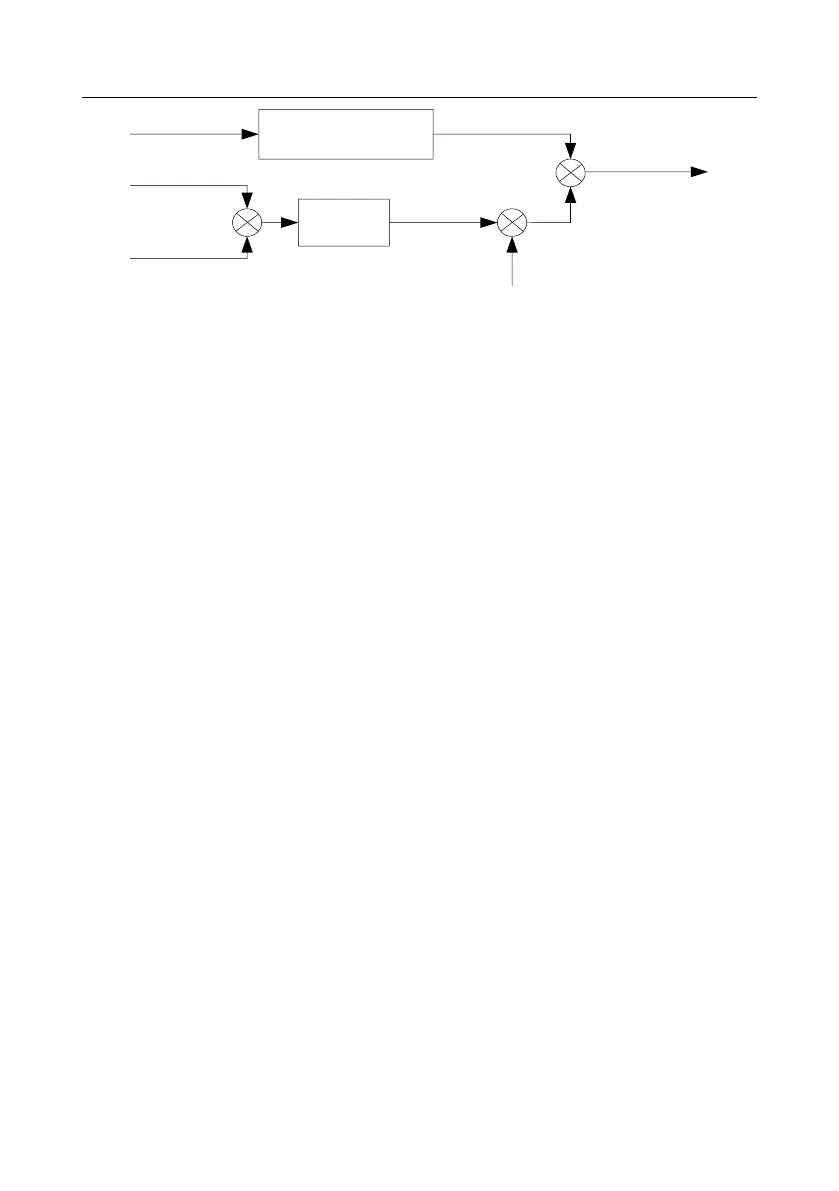

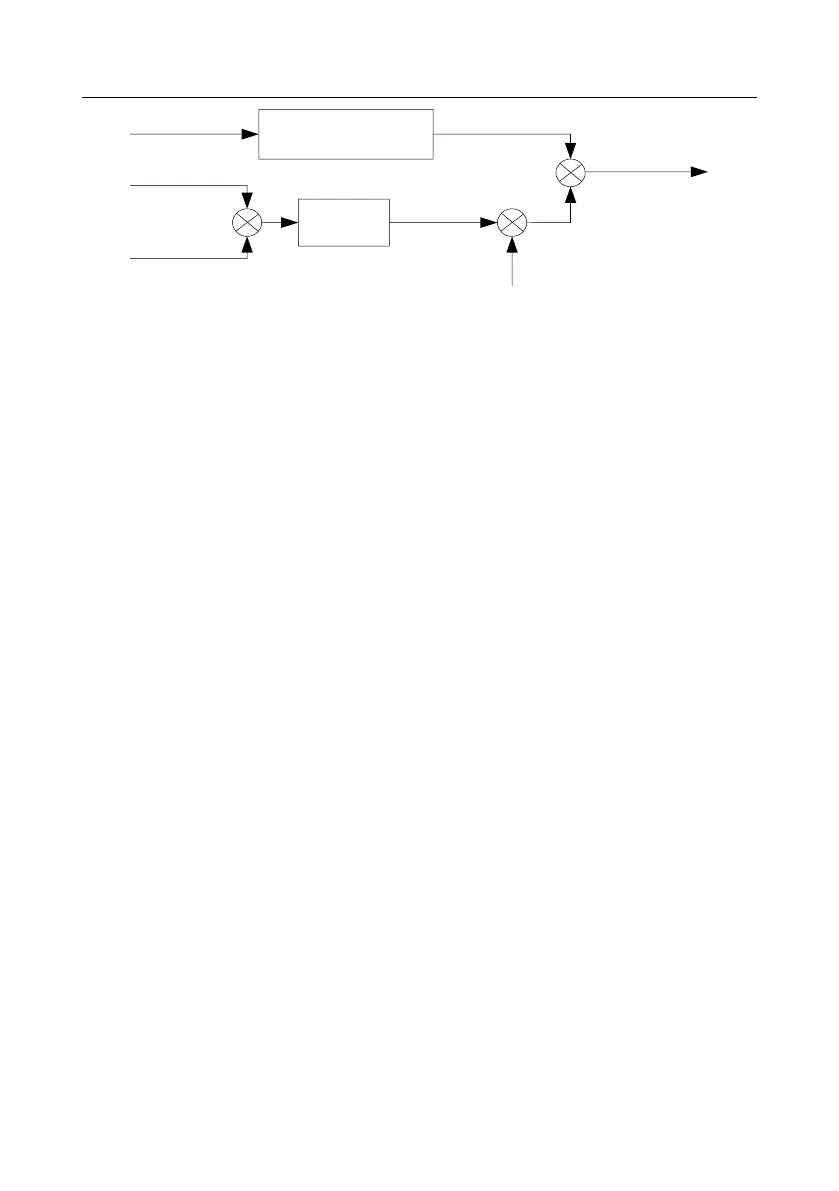

5.5.20.4 Closed-loop torque mode

Similar to the open-loop torque mode, the closed-loop torque mode has only the difference that

tension detection sensors are installed on the winding/unwinding side. In addition to all the function

modules supported in open-loop torque mode, this mode supports an additional tension feedback PID

closed-loop regulation module. The control principle is shown in the following figure.

Loading...

Loading...