HD2 Series Inverter Basic Operation Guidelines

-131-

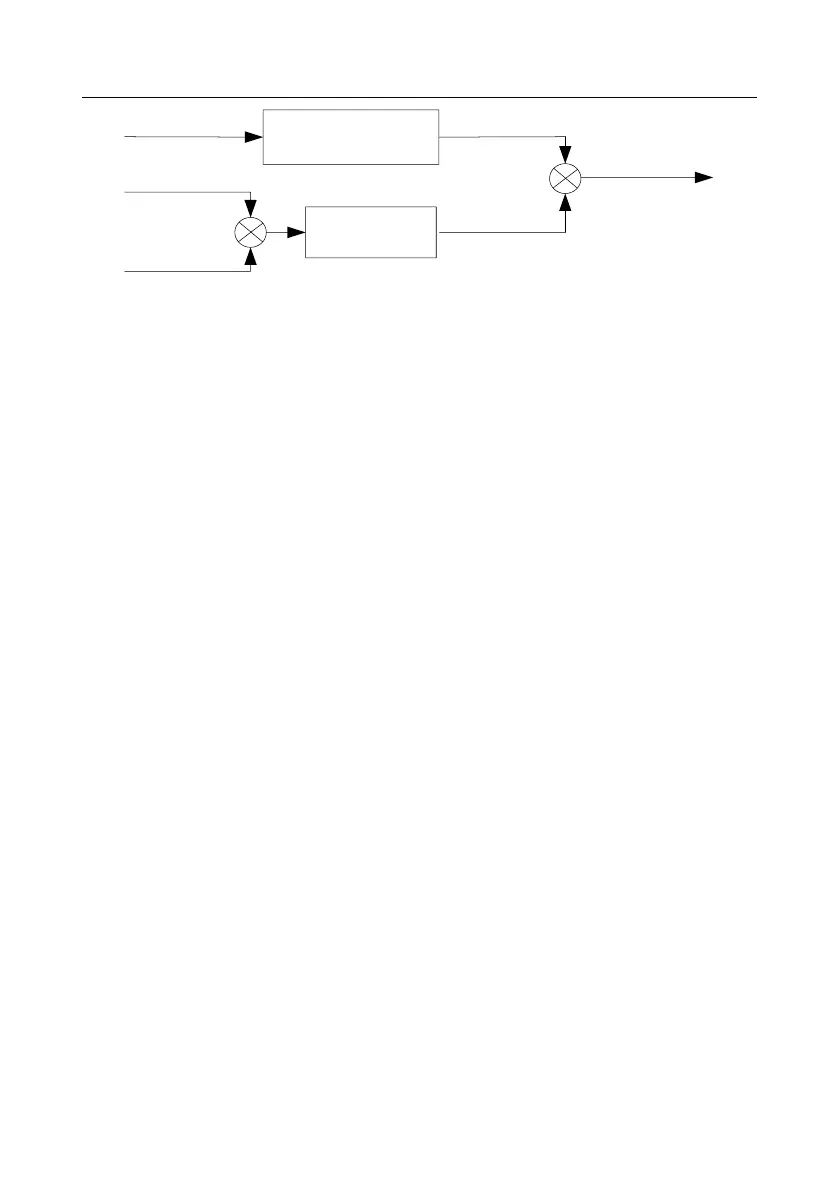

Calculate the frequency

according to the linear

speed

PID regulation

+

+

Linear speed

Tension reference

Tension feedback

Basic reference frequency

Inching

frequency

Motor reference

frequency

+

-

Related modules:

(1) Linear speed input module: It is important for the calculation of the basic setting frequency

according to the linear speed and the calculation of roll diameter according to the linear speed.

(2) Real-time roll diameter calculation module: The calculation accuracy of roll diameter determines

the control performance. The roll diameter can be calculated according to the inverter output

frequency and the linear speed. In addition, it can also be calculated through the thickness or sensor.

The linear speed is widely used for the calculation. If the set linear speed is used for the calculation,

you you choose whether to enable the function of roll diameter change limiting.

(3) PID regulation module: There are two groups of PID parameters in P09. The linear speed

synchronization and stable tension can be kept through PID regulation. PID parameters can be

modified based on site commissioning. The two groups of PID parameters can be switched for PID

regulation improvement.

(4) Material feeding interrupt detection and processing module: The function is valid when material

feeding interrupt detection has been enabled.

(5) Pre-drive: This function is applied to automatic reel change. After the inverter is started if the

pre-drive function terminal is valid, the roller runs at the set linear speed. When the terminal is invalid,

the inverter will automatically switch to the corresponding control mode after a period.

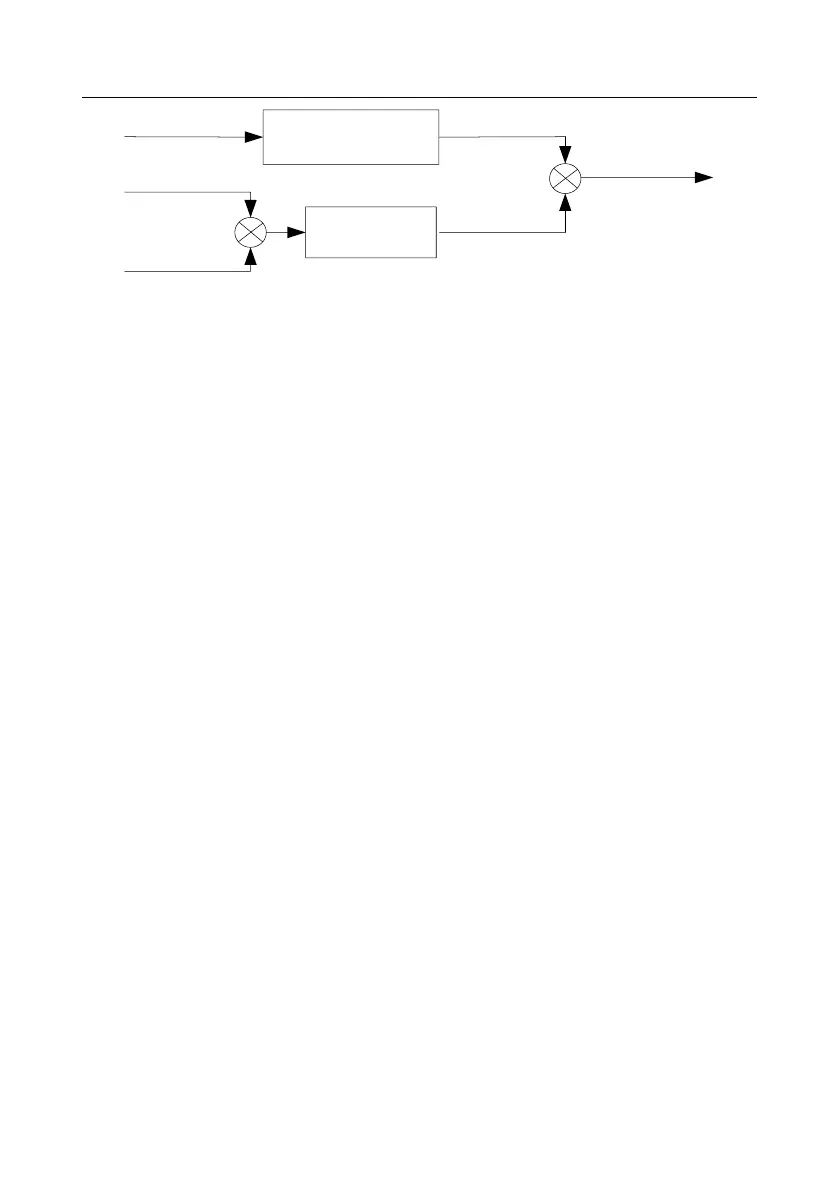

5.5.20.3 Open-loop torque mode

Open loop means there is no tension feedback signal. In this mode, stable tension can be achieved

by means of motor torque control. The rotation speed automatically changes with the linear speed of

material. The control basis is as follows: For a reel control system, the relationship between the

tension F of the roller with materials, present roll diameter D and output torque of the shaft is: T = F ×

D /2. If the output torque can be adjusted according to the variation of roll diameter, the tension can

be controlled. To ensure the constant tension in the process of acceleration and deceleration, the

internal friction compensation module and inertia compensation module have been built in the

inverter to calculate the real time rotation inertia and compensate the torque according to the actual

speed change rate. The control principle is shown in the following figure.

Loading...

Loading...