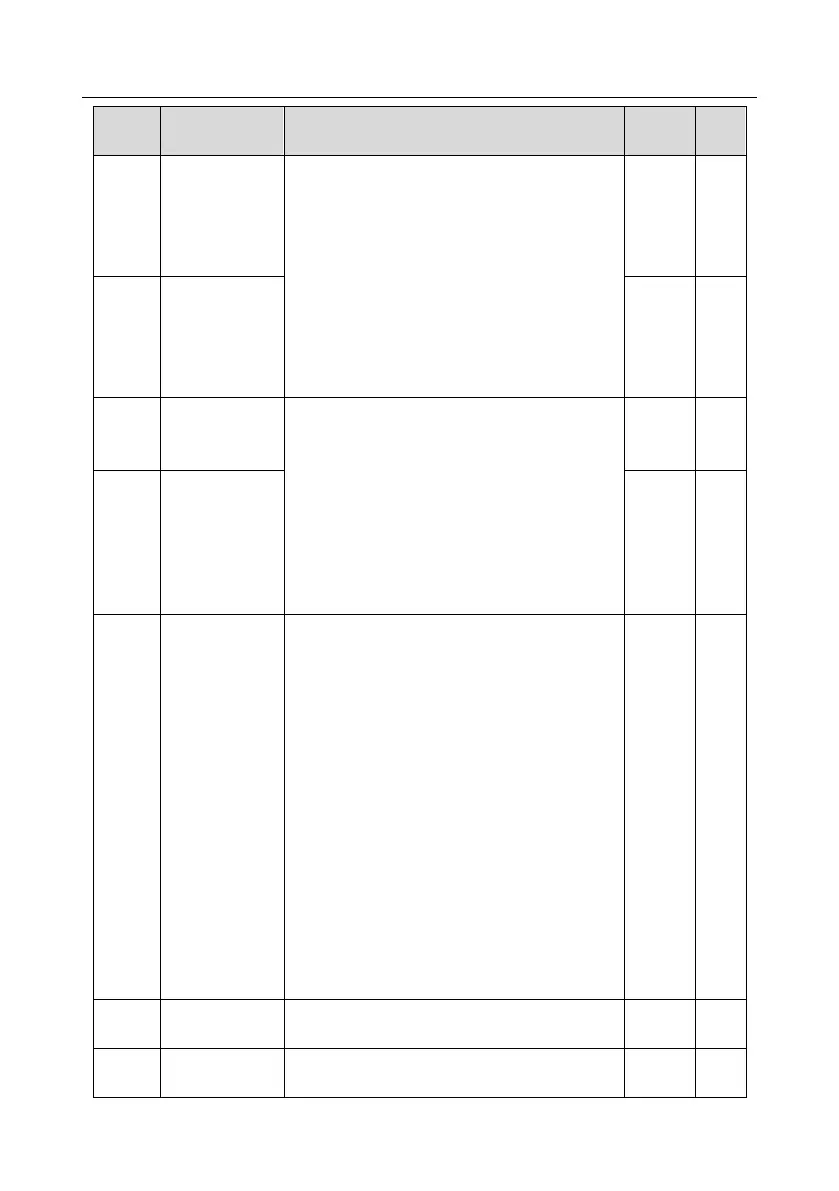

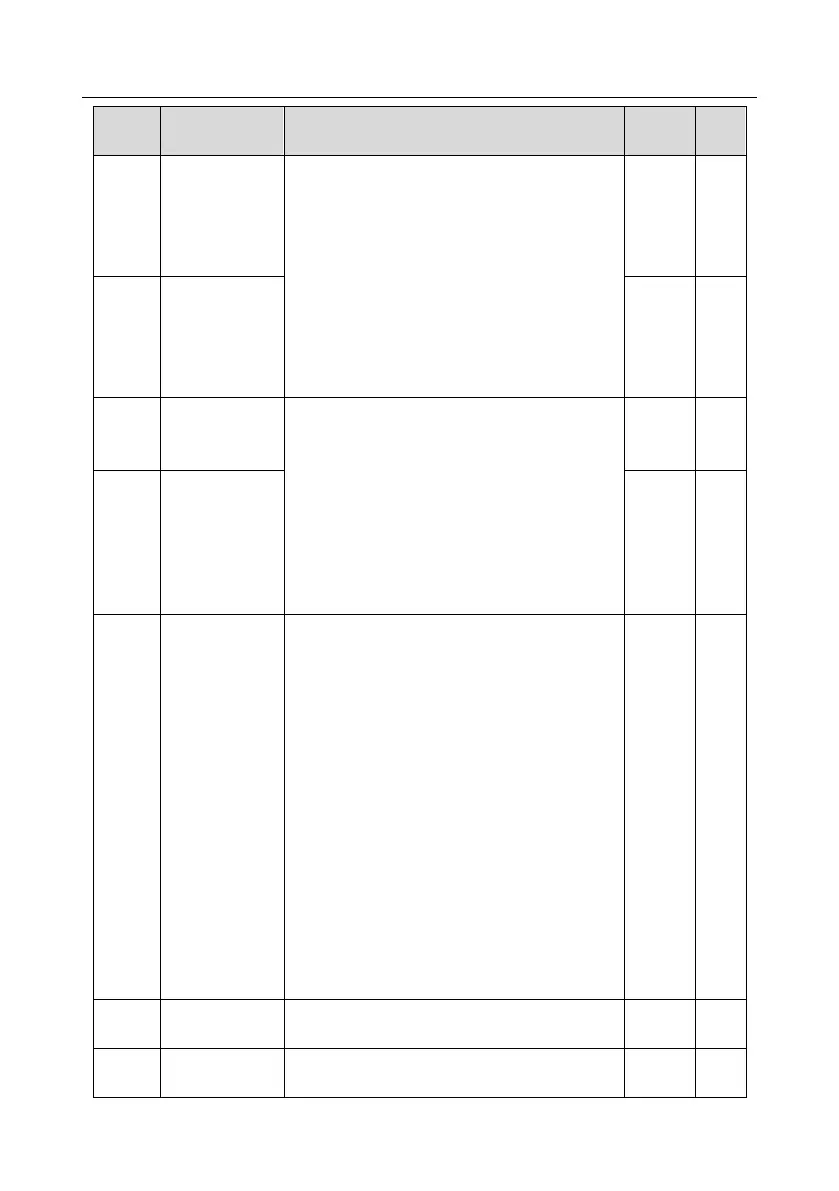

HD2 Series Inverter Function Parameter List

-150-

Vector control

slip

compensation

coefficient

(motoring)

Slip compensation coefficient is used to adjust the

slip frequency of vector control to improve speed

control precision. This parameter can be used to

control speed offset.

Setting range: 50–200%

Vector control

slip

compensation

coefficient

(generating)

Current loop

proportional

coefficient P

Note:

1. These two parameters are used to adjust PI

parameters of current loop; it affects dynamic

response speed and control precision of the

system directly. The default value needs no

adjustment under common conditions.

2. Applicable to SVC mode 0 (P00.00=0), SVC

mode 1 (P00.00=1), and FVC (P00.00=3)

Setting range: 0–65535

Current loop

integral

coefficient I

0–1: Keypad (P03.12)

2: AI1

3: AI2

4: AI3

5: Pulse frequency HDIA

6: Multi-step torque

7: Modbus/Modbus TCP communication

8: PROFIBUS/CANopen/DeviceNet

communication

9: Ethernet communication

10: Pulse frequency HDIB

11: EtherCAT/PROFINET/EtherNet IP

communication

12: Programmable card

Note: For these settings, 100% corresponds to the

motor rated current.

Torque set

through keypad

-300.0%–300.0% (of the motor rated current)

Torque reference

filter time

Loading...

Loading...