5.2011.8583.0 C

6-18 Maintenance Procedures

Do not use an impact wrench.

If the old strip was shortened, make sure the new strip is shortened at the same length.

If an extra hole was made in the old strip at 35 mm (1.4 in) from the cut part, make a hole

with a diameter of 11 mm (0.43 in) in the new strip at the same location.

Only the hole (A) in the center is round, the holes B and C are slots to allow the metal

strip to shrink and expand a bit with temperature changes.

The metal strips are not symmetrical, if a hole in the concrete can not be used anymore,

you can turn the strip over the long side and drill new holes in the concrete.

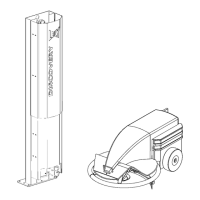

Figure 64. Metal strips

KEY:

A: Round hole

B: Slotted hole

C: Slotted hole

L = left; R = Right

Turn the strip

1. Remove the screws and turn the strip (left side becomes the right side).

2. Drill the holes with a 10 mm drill and >65 mm deep, drill in the in the new center (A) of the strip and in

the center of the slotted holes (B) and (C).

3. Clean the floor and holes from drilling waste.

4. Turn the screw (BT 6x65) a bit in the duo plug.

5. Use a hammer to insert the plug and screw through the metal strip. Make sure the top of the plug is

level with the concrete.

6. Use a bit T30 to tighten the metal strip with the screws (BT 6x65). Tighten only with a torque of 20 Nm,

it must still be possible to move the strip.

Replace the metal strip

1. Remove the screws, plugs and old metal strip.

2. Put the new strip on the floor, make sure the Mixing and Feeding Robot will find the metal strip on the

exact same position as the old one.

3. If possible use the old holes.

in n o vato rs in agriculture

Loading...

Loading...