LB 9507 Chapter 2: Design of the Lumat

2-7

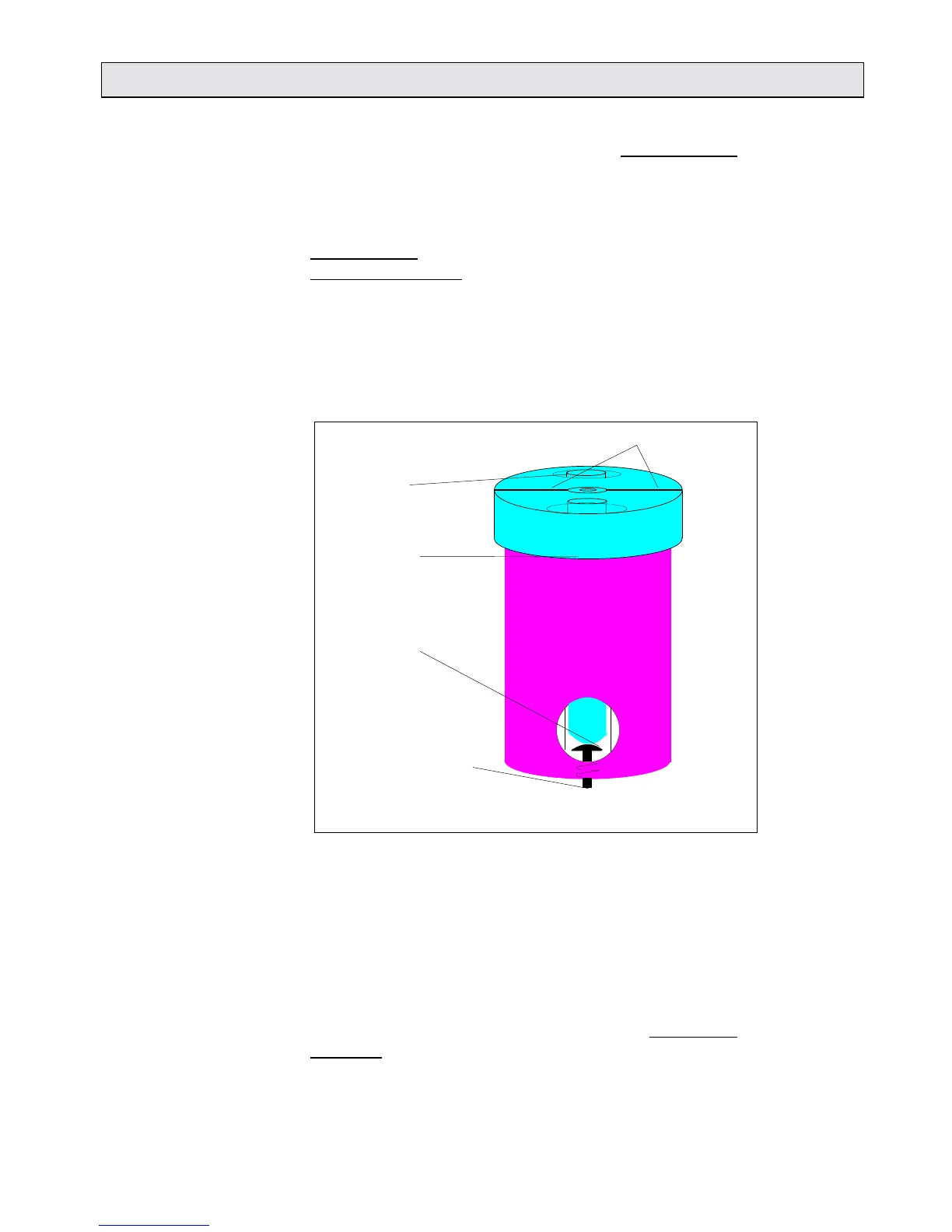

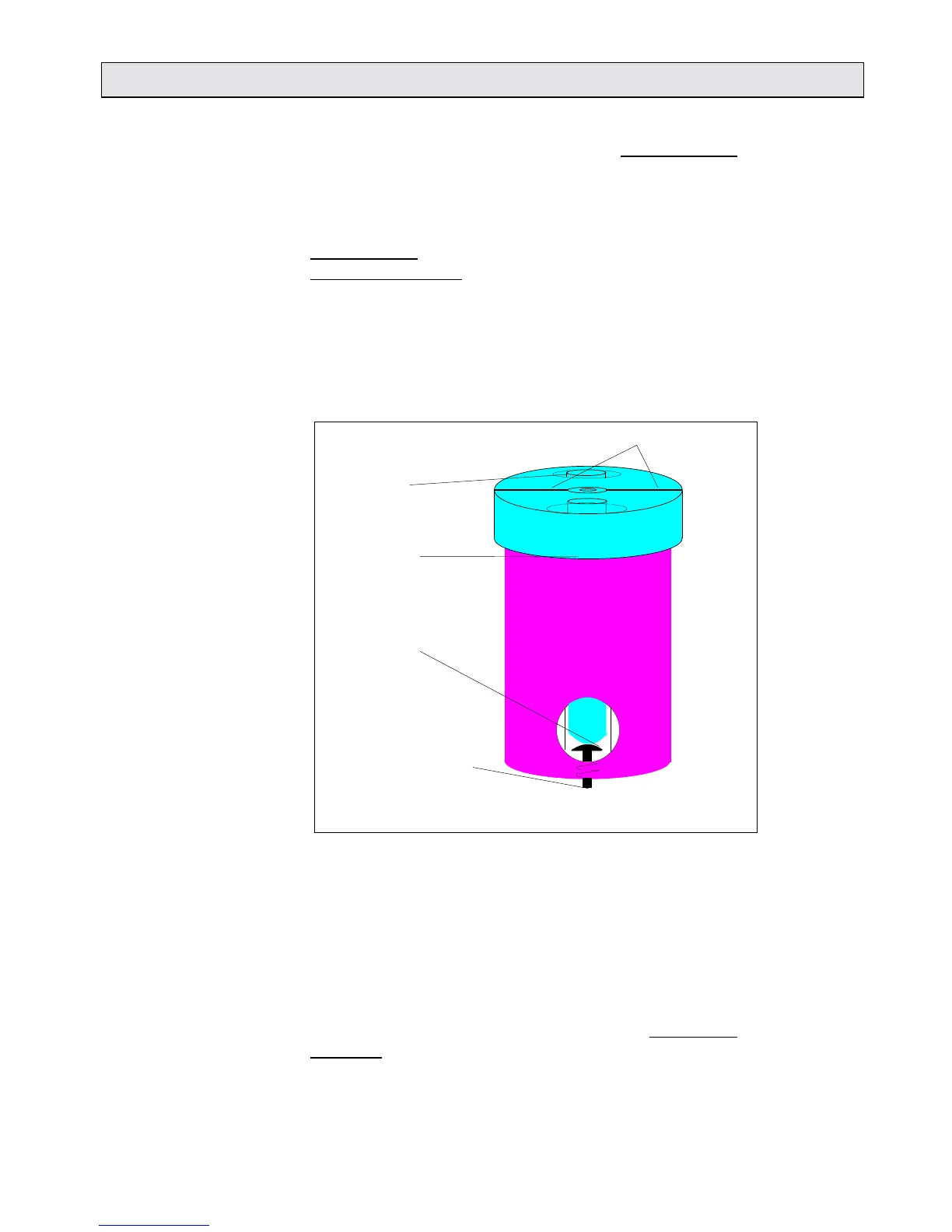

Tube transport rotor The tube transport rotor is made of a special conductive plastic

which prevents electrostatic charges from building up.

The rotor contains two holes positioned opposite each other, and

each can hold a sample tube, meaning that one hole is always in

loading position (at the front, facing the user) and one in

measurement position. Pressing a button (<START> when

measuring, or the softkey <TURN ONCE>) causes the rotor to

turn through 180°, thus switching the positions of the tubes. The

tube in the loading position is lifted by a spring-pin so that it is

easier to take out (see Figs. 2-5 and 2-6). This rotation principle

allows samples to be loaded and measured at the same time.

Sealing lips (spring-loaded)

Fig. 2-6: Tube transport rotor

To distinguish between the two measurement chambers, one

of them is marked with a red spot. This measurement

chamber is called the "red" chamber, the other is called the

"black" chamber.

The top of the tube transport rotor includes two spring-loaded

sealing lips which shield the measurement chamber from light.

Tube in

measurement

position

Tube in

loading position

(pushed up)

Measurement chamber:

the rear surface

is mirrored to

increase the

light again

Spring pin:

the tube sits on

the spring pin; in the

loading position it is -

pushed up by a

sloping base

Loading...

Loading...