106

Mahr GmbH • Digimar 817 CLM

7.6 Control limits based on measuring

values

1. <-_______

2. Learn programming (teach - in)

3. Create new program

4. Change existing program

5. Print out current program

6. UCL / LCL computation (measured values)

7. UCL / LCL computation (tolerances)

8. Menu program file management

9. Menu data file management

10.Program START

In order to compute the control limits, usually 50

workpieces of a homogeneous lot are inspected.

A lot is considered homogeneous if all workpieces

were

produced one after the other in the usual

manufacturing

rhythm and all measured workpieces are within the

tolerance limits.

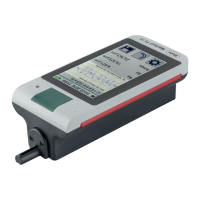

Compute UCL and LCL

PRG1 09:57 04/Sep/06 755

TEST1 09:59 04/Sep/06 1175

TEST5 10:18 04/Sep/06 587

248/8083 Read. 3/80 blocks 3/40 Files

ON

OFF

Start : 01.02.2007 Stop: 28.02.2007

MACHINE 5 TESTING

OPERATOR 2 BROWN

SHIFT 2 S2

TOOL 2 MEDIUM

CUSTOMER 2 BB

SAMPLE COMM 4 Q4

All parts Parts n.:1 - 9999

ON

OFF

** 100 % monitoring required **

Step : 2. Contact above

-0.1879 : Cpk is too low!

1. Copy new limits into program

2. Maintain old control limits

Calculation takes place

The control limits are computed on the basis of all

measuring values saved under the name of the

measuring program. Therefore, the automatic

computation of control limits should only be used for

newly created programs.

Please remember that control limits for an existing

program can only be calculated and entered anew, if

the Cpk value is larger than 1.00. (For values below

1.00, a warning is given).

Loading...

Loading...