53

Mahr GmbH • Digimar 817 CLM

4.4.2 Measuring the perpendicularity error

Determine the perpendicularity error with either an incremental

probe or a digital indicator

– Connect the incremental probe P1514 H via the INPUT 2

interface or the digital indicator

1081, 1086 / 87 to a 16 EXr data cable via. the INPUT 1

interface.

– Press the menu key and under the perpendicularity error select

the required input.

Input 1: (e. g. 1086 / 1087) Digital indicator

Input 2: P1514 H Incremental probe

A maximum of 500 measuring points can be accepted. Depending

upon the speed and the measuring instrument (350/600/1000 mm)

the number of measuring points and the set measuring track can

alter accordingly.

– Mount the probe into the holder on the measuring carriage

– Select the perpendicularity error function

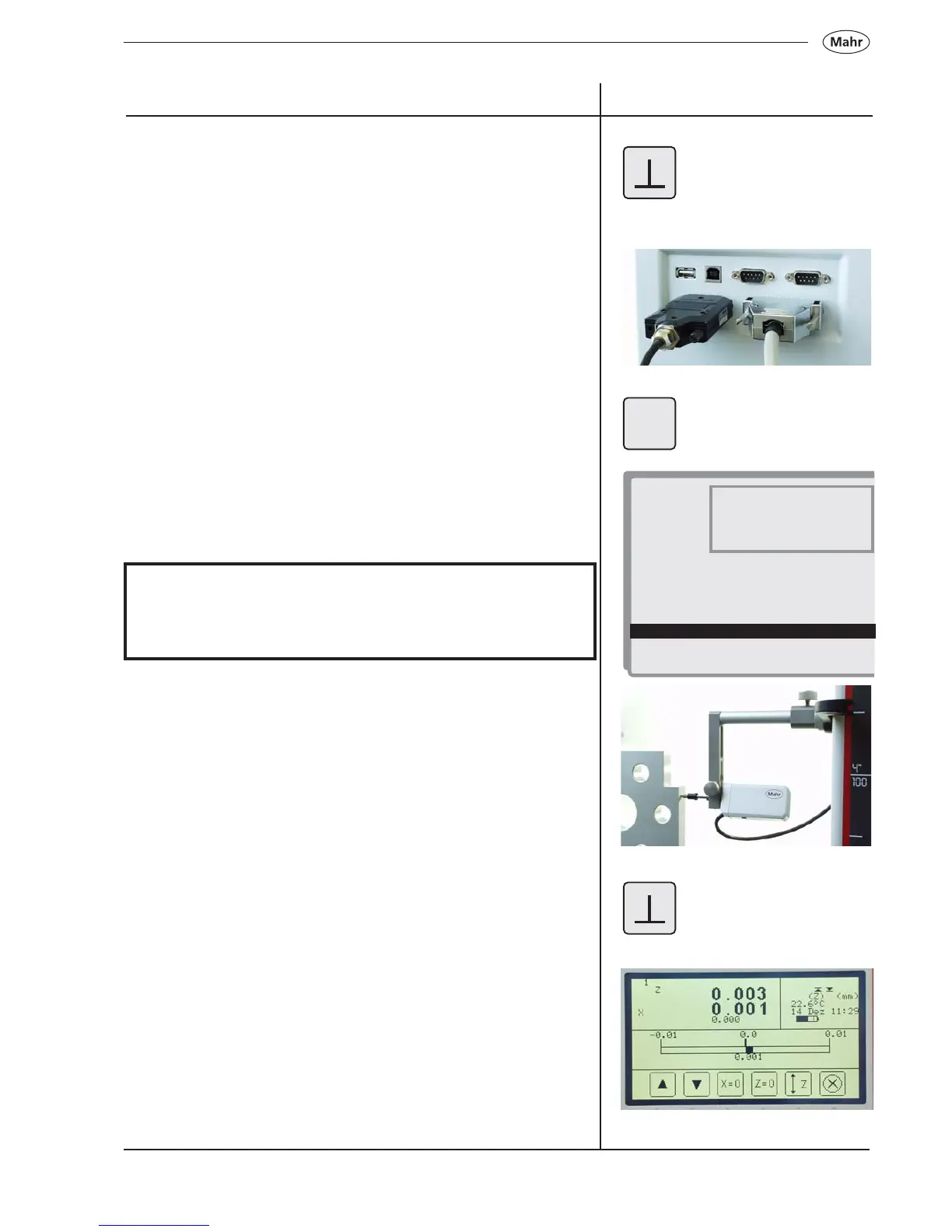

Description / Sequence Symbols / Pictures

MENU

1 23456

1 = Start an upwards measurement

2 = Start an downwards measurement

3 = Set the X-value to zero

4 = Set the Z-value to zero

5 = Enter the measuring path

6 = Abort

1. <-_______

2. Standstill-time

3. Contacting speed

4. Resolution

5. mm/inch

6. Language

7. Date and time

8. LCD settings

9. Beep ON/OFF

10. Auto – off time (min)

11. Quick-Mode

12. Perpendicularity

13. Data and printer

14. Advanced settings

1. Input 1 (OPTO-RS232)

2. Input 2 (P1514 H)

Loading...

Loading...