70

Mahr GmbH • Digimar 817 CLM

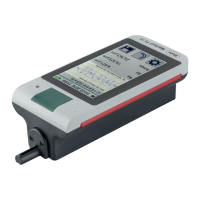

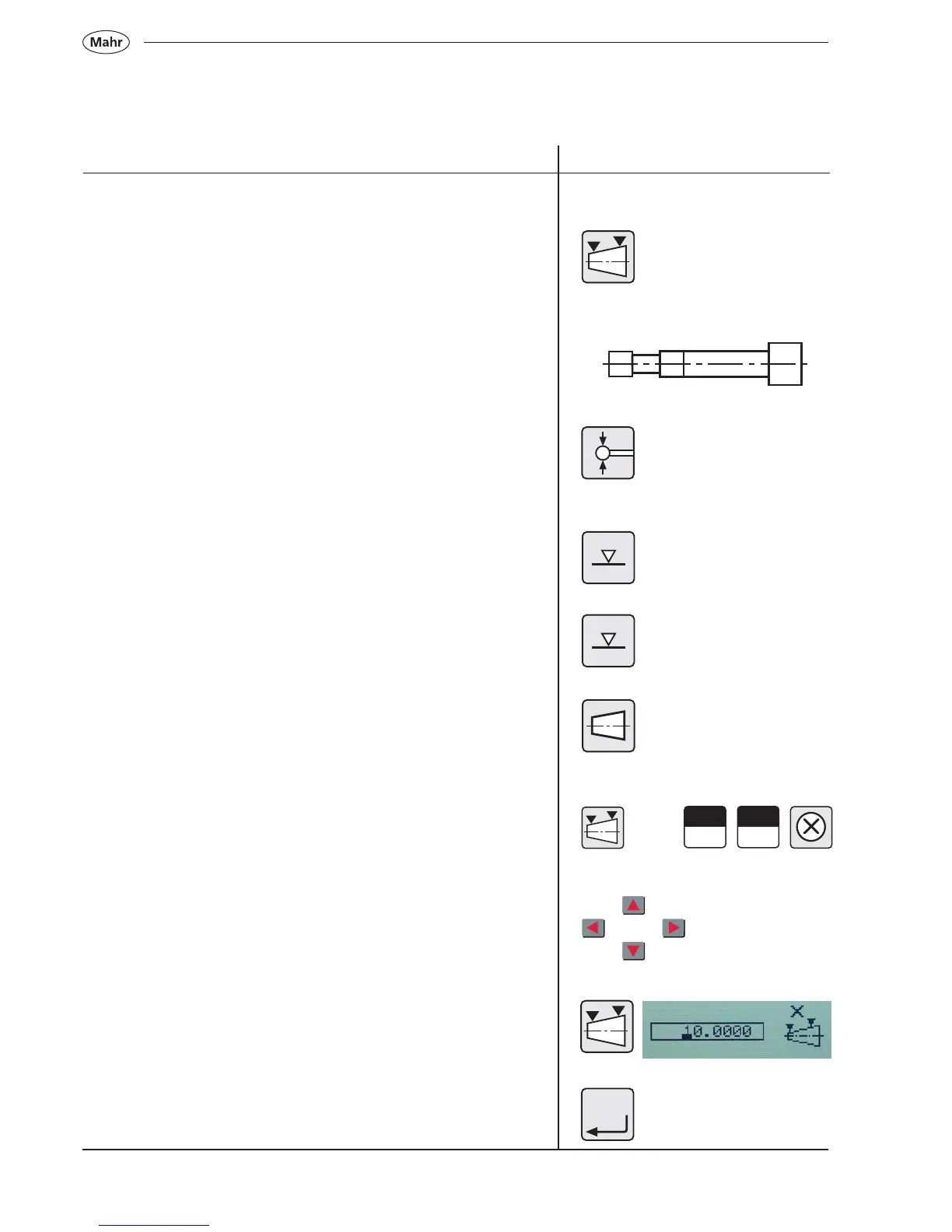

4.6 Measuring a taper / calculating an angle

On a taper, the angle α between its mean line and the base plate is to

be determined. It must be possible to laterally displace the workpiece

by a clearly defined amount. To do this, attach a stop to the base plate

and place a gage block between the stop and the workpiece.

A gage block is required, which is somewhat shorter in length than the

height of the taper.

For the measurement, a probing element with cylindrical styli is

necessary which must be aligned parallel to the base plate.

Procedure

– Calibrate a cylindrical probe (standard or with a groove),

see chapter 2.1

– Place the gage block between the workpiece and the stop and

position the probe above the narrow end of the taper.

– Contact from above (arrow 1)

– Remove the gage block and slide the workpiece towards the stop

until it makes contact

– Contact from above (arrow 2)

– Press the taper function key

The following menu will appear:

– Using the arrow keys select characteristic A and characteristic B

(use the function keys A and B to accept them)

– Press taper evaluation and enter the dimension 10.000

– Confirm – angle will be displayed

Description / Sequence Symbols / Pictures

ON

OFF

B

A

Loading...

Loading...