Manitowoc Published 06-24-16, Control # 241-01 4-117

2250 OPERATOR MANUAL SETUP AND INSTALLATION

Anchoring Wire Rope to Drum

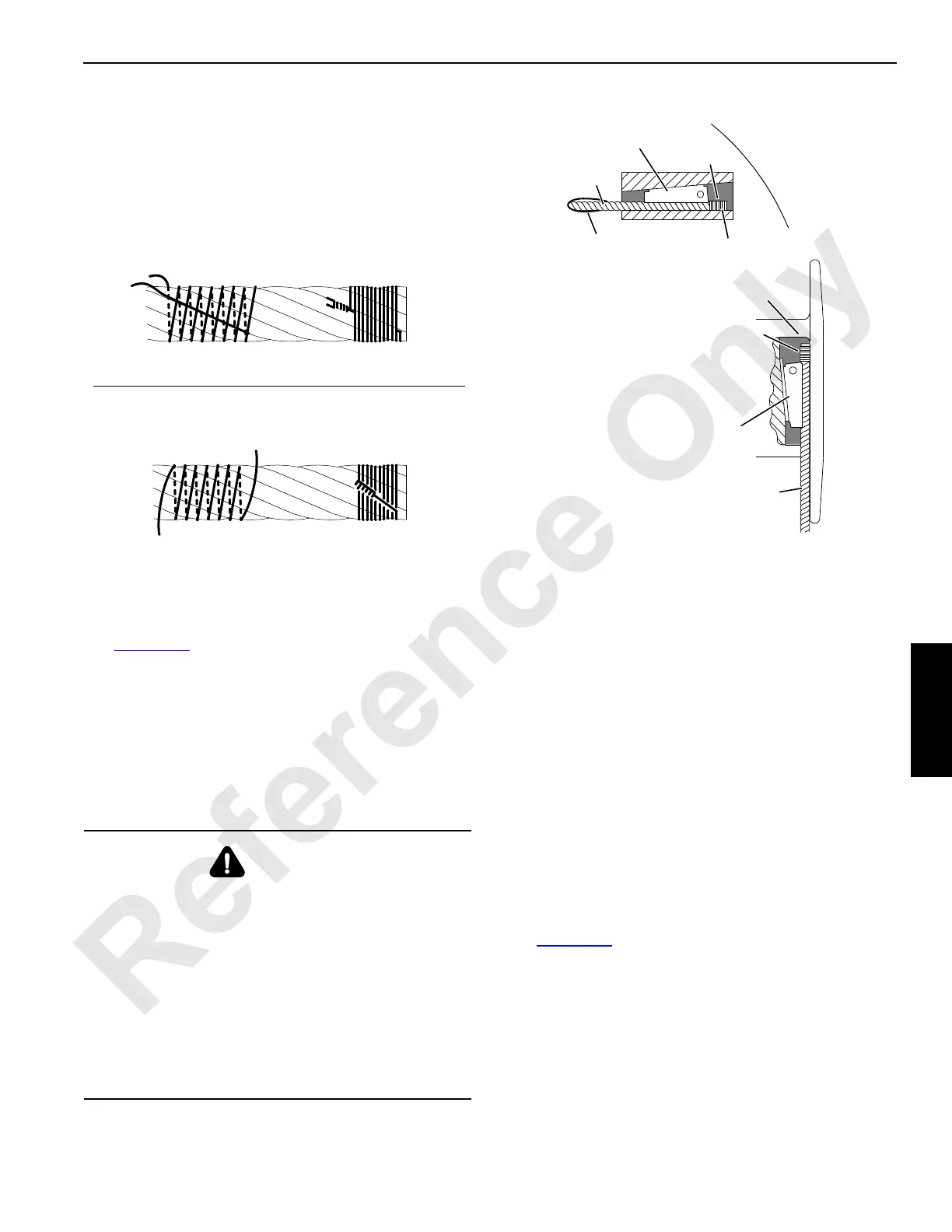

See Figure 4-63 for the following procedure.

Use the correct wedge part number for the size of wire rope

being used. See the parts drawing to obtain the correct part

number for the boom hoist drums or for the load drum shaft.

1. Assemble the wire rope and the wedge to the drum

socket.

2. Tighten the wedge, rapping the back of the wedge with a

brass drift pin and hammer.

Winding Wire Rope onto Drum

See the Drum and Lagging Chart in the Capacity Chart

Manual for the correct size of drum laggings, if used.

See the Wire Rope Specifications Chart in the Capacity

Chart Manual for the correct type, size, and amount of wire

rope to be installed on the load drums.

See the Boom Rigging drawing for the correct type, size, and

amount of wire rope to be installed on the boom hoist drums.

1. Carefully inspect the drums and all the rope guides,

rollers, and sheaves for defects that can cause the wire

rope to wear or be cut. If the defects cannot be fixed,

replace the faulty parts.

2. Apply tension to the wire rope as it is being wound slowly

onto the drum.

The first wrap must be tight against the drum flange for

approximately three-fourths of the drum diameter

(Figure 4-64

).

3. Tap the adjacent wraps against each other with a soft

metal or wooden mallet.

Use extreme care not to put twists or turns in the wire

rope. Allow the rope to assume its natural lay.

WARNING

Falling Load Hazard!

Prevent possible injury. Wire rope can be pulled out of the

drum if the following steps are not taken:

• Install a straight wedge so the corrugated side is

against the wire rope.

• Install the wedge so the end of the wire rope extends

past the end of the wedge, but not out of the drum

socket.

• Make sure seizing is not under the wedge. Remove

the seizing if it interferes with the assembly.

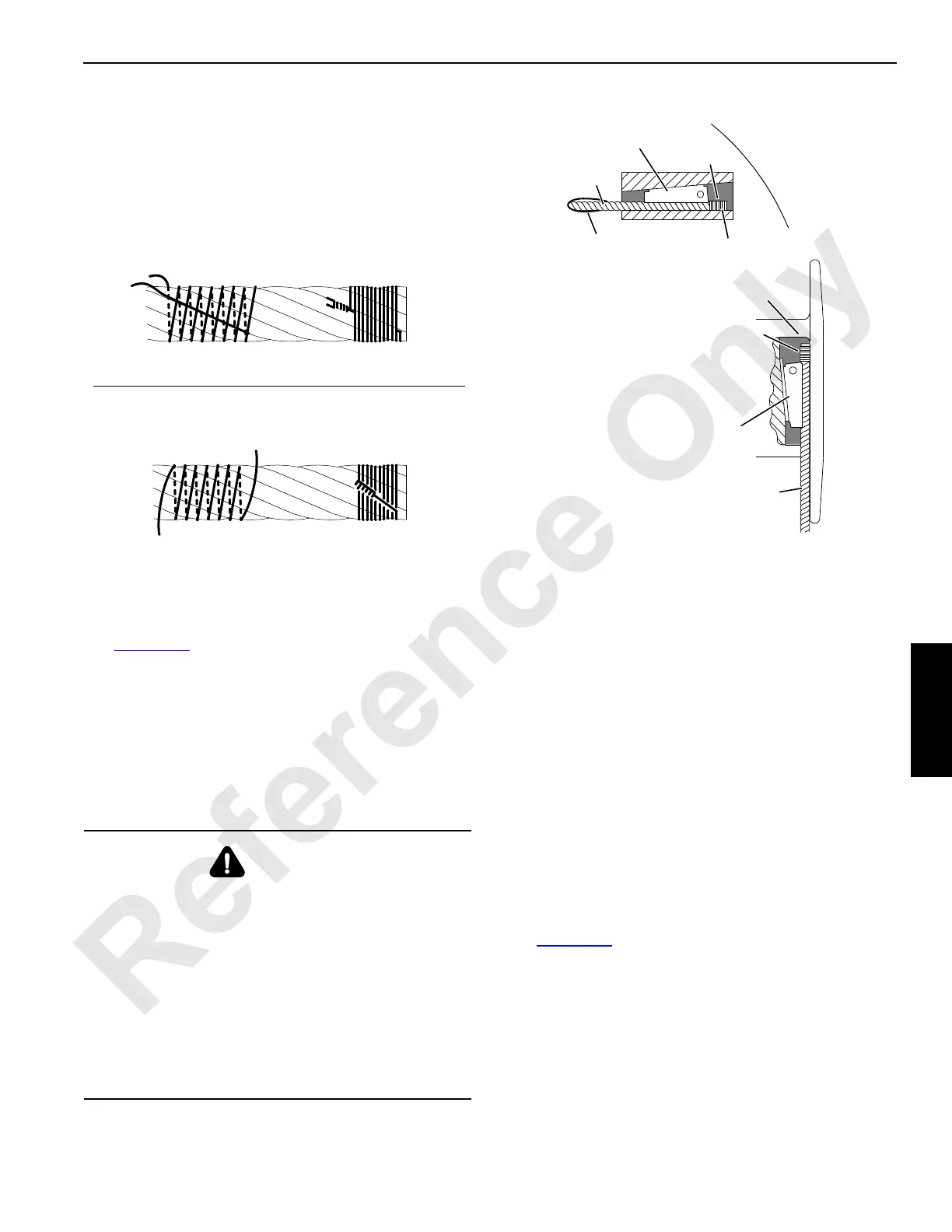

FIGURE 4-62

Place the free end of the seizing wire in the valley between the

two stands. Then wind the seizing wire over the free end as

shown. Finally, twist and pull the two ends of the seizing wire

together until the seizing is tight.

View A

A925

Rope Diameter 26 mm (1 in) and Larger

View B Rope Diameter Smaller than 26 mm (1 in)

Wind the seizing wire around the wire rope as shown. Then twist

the two ends of the seizing wire together at the center of the

seizing. Alternately twist and pull the ends until the seizing is

tight

.

Wire Rope Type

Seizings

Required

Preformed

1

Non-preformed

3

FIGURE 4-63

Hole in

Drum Flange

Straight Wedge

Inside Drum

Straight Wedge

Outside Drum

Do not allow the end of

the wire rope to extend

out of the socket

opening

Seizing

Seizing

Wire

Rope

Wire

Rope

Loading...

Loading...