OPERATING CONTROLS AND PROCEDURES 2250 OPERATOR MANUAL

3-72

Published 06-24-16, Control # 241-01

• Use the left pedal (right rear drum) to apply the drum

working brakes.

• Use the control handle corresponding to the drum that

has the load line installed on it. This will reduce torque

on the drive lug.

Full Power Mode

Use the drum interlock in the Full Power mode when the

added security of a dual park brake and clutch application is

desired during critical lifts.

Drum interlock in the Full Power mode only requires

installing a drive lug between the drums. It is not necessary

to modify or reroute the drum working brake air lines,

because in the Full Power mode, the drum park brake stops

the drum. The drum working brake is used only when

necessary to stop the drum. One working brake has

sufficient torque to perform this function.

Drum interlock in the Full Power mode requires the drums to

be operated in the tandem drum mode. In Tandem mode, the

crane’s programmable control automatically selects the left

side control handle (right drum) as the active handle. The

other handle is inoperable.

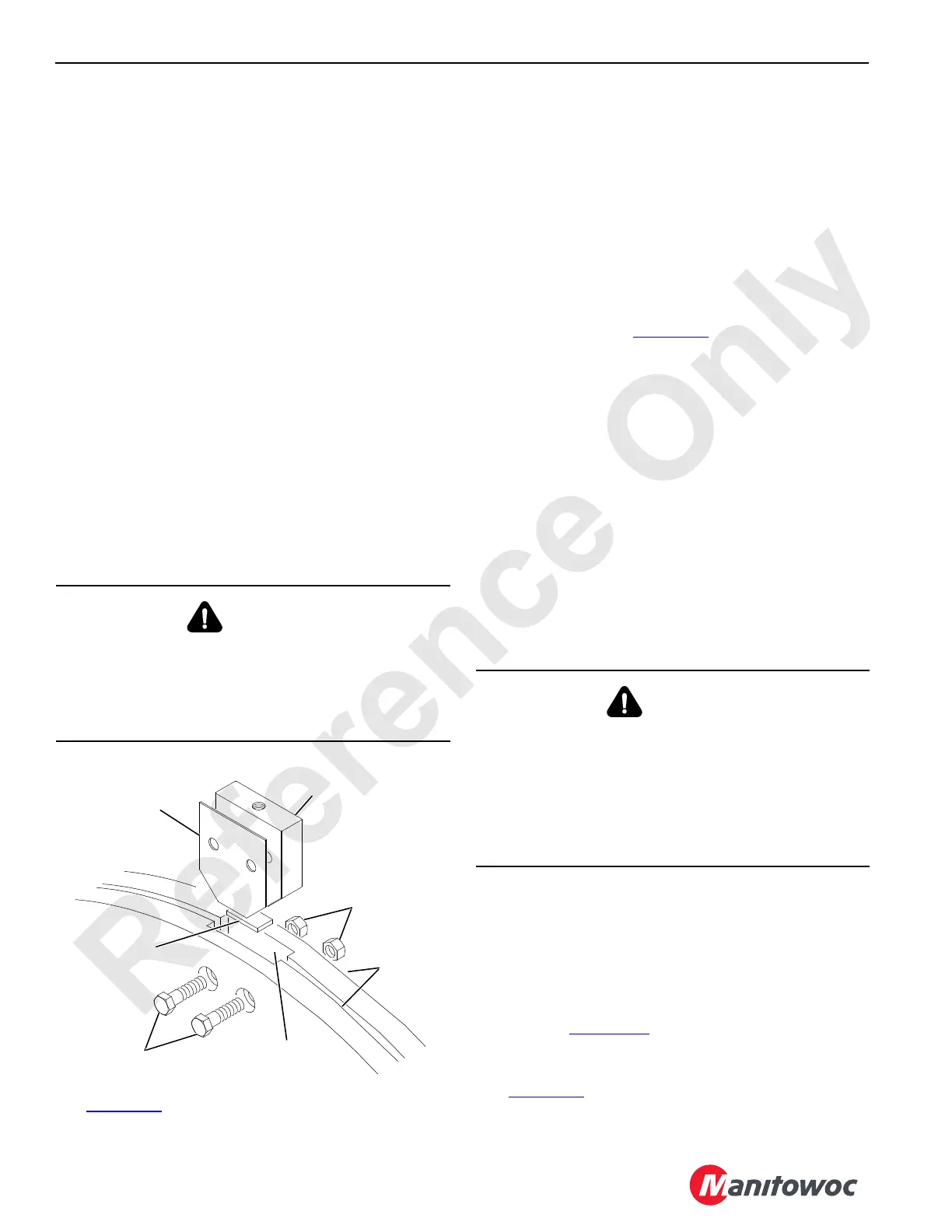

Installing Drum Interlock

See Figure 3-56 for the following procedure.

1. Land the load on both drums so the wire rope is slack.

2. Remove the load line from the drum not to be used.

3. Operate the drums to align the keyways in the drum

flanges as shown.

4. Install the flat bar and drive lug in the keyways as shown.

Use shims so the drive lug is snug in the keyways.

5. Apply thread-locking compound to the screw threads,

fasten the nuts to the screws, and securely tighten the

nuts so they cannot loosen.

6. Modify the drum working brake air lines to allow drum

interlock operation (Figure 3-58

, View B).

This modification is not required for operation in the Full

Power mode, but it can be made if dual working brake

operation is desired.

a. Fully release both drum working brake pedals to

exhaust air from the air lines between the brake

chambers and the treadle valves.

b. Install a tee (1) in air line B with nuts (3) and ferrules

(2).

c. Connect jumper air line C to the tee (1) with a nut (3)

and ferrule (2).

d. Securely fasten the female connector (4) and plug

(5) to the free end of air line A with a nut (3) and

ferrule (2).

e. Make sure all fittings are tight to prevent air leaks.

Removing Drum Interlock

1. Land the load on both drums so the wire rope is slack.

2. Fully release both drum working brake pedals to exhaust

the air from the air lines between the brake chambers

and treadle valves.

3. Remove the drive lug, shims, and flat bar from the

keyways (Figure 3-56

). Store all parts.

4. If the drive lug is seized to the keyways, use a bar and

bolt to jack the drive lug out of the keyways

(Figure 3-57

).

WARNING

Falling Load Hazard!

Avoid the possibility of death or serious injury. The load

will fall if the load lines are not slack. Land all loads so the

load lines are slack before installing the drive lug or

disconnecting the air lines.

FIGURE 3-56

A583

Shims

Drive Lug

Nuts

Flat Bar

Capscrews

Keyways

Drum

Flanges

WARNING

Falling Load Hazard!

Death or serious injury to personnel can result. The

working brake must be applied to stop the load when the

drum control handle is released to OFF. Otherwise, the

load will lower uncontrolled.

Be aware of which working brake pedal is active when

operating with drum interlock in Free Fall mode.

Loading...

Loading...