SETUP AND INSTALLATION 2250 OPERATOR MANUAL

4-38

Published 06-24-16, Control # 241-01

3. Rotate the front jacks to the horizontal “wing” position

(Figure 4-12

, View D). Pin the struts to the jacks

(Figure 4-8

, View A).

4. Swing the operator’s cab to the intermediate position

and pin in place (Figure 4-10

).

5. Rotate the rear jacks to the operating position

(Figure 4-8

). Pin the struts to jacks.

6. Install the jack pads (Figure 4-7

, View E).

7. Extend the rear jacks until the carbody pedestals can be

installed.

Remove two pedestals from storage (Figure 4-7

,

View B) and install them under the carbody (Figure 4-12

,

View A).

NOTE: Make sure the pedestals engage the support pads.

8. Retract the rear jacks and rotate to the horizontal “wing”

position (Figure 4-19

, View C).

9. Swing the rotating bed over the other crawler.

10. Repeat step 5

, through step 7 for the remaining two

carbody pedestals.

11. Ensure the carbody is level. Adjust the jack screws to

the level assembly (Figure 4-12

, View A).

Remove Crawlers

1. Position an empty trailer along the desired side of the

carbody (Figure 4-17

).

2. Start the engine. Swing the rotating bed and boom up so

that the assembly block is centered over the crawler.

3. Connect the crawler handling chain assembly to the

hook of the assembly block.

4. Unpin the drive shaft guard (Figure 4-18

, View D) and

slide the guard back.

5. Remove the flange screws from the drive shaft flange

(Figure 4-18

, View C). Store the screws in the flange.

6. Retract the crawler drive shaft and place the drive shaft

on the supporting bracket (Figure 4-18

, View B).

7. Connect three legs of the chain assembly to the lugs on

the crawler frame (Figure 4-17

, View A).

8. Remove and store the retaining pins (Figure 4-18

,

View A) and disengage the crawler frame pins with the

control on the setup remote control. Pins should be fully

disengaged within 10 seconds.

9. Visually check that both crawler frame pins are fully

disengaged. If either pin fails to disengage, proceed as

follows:

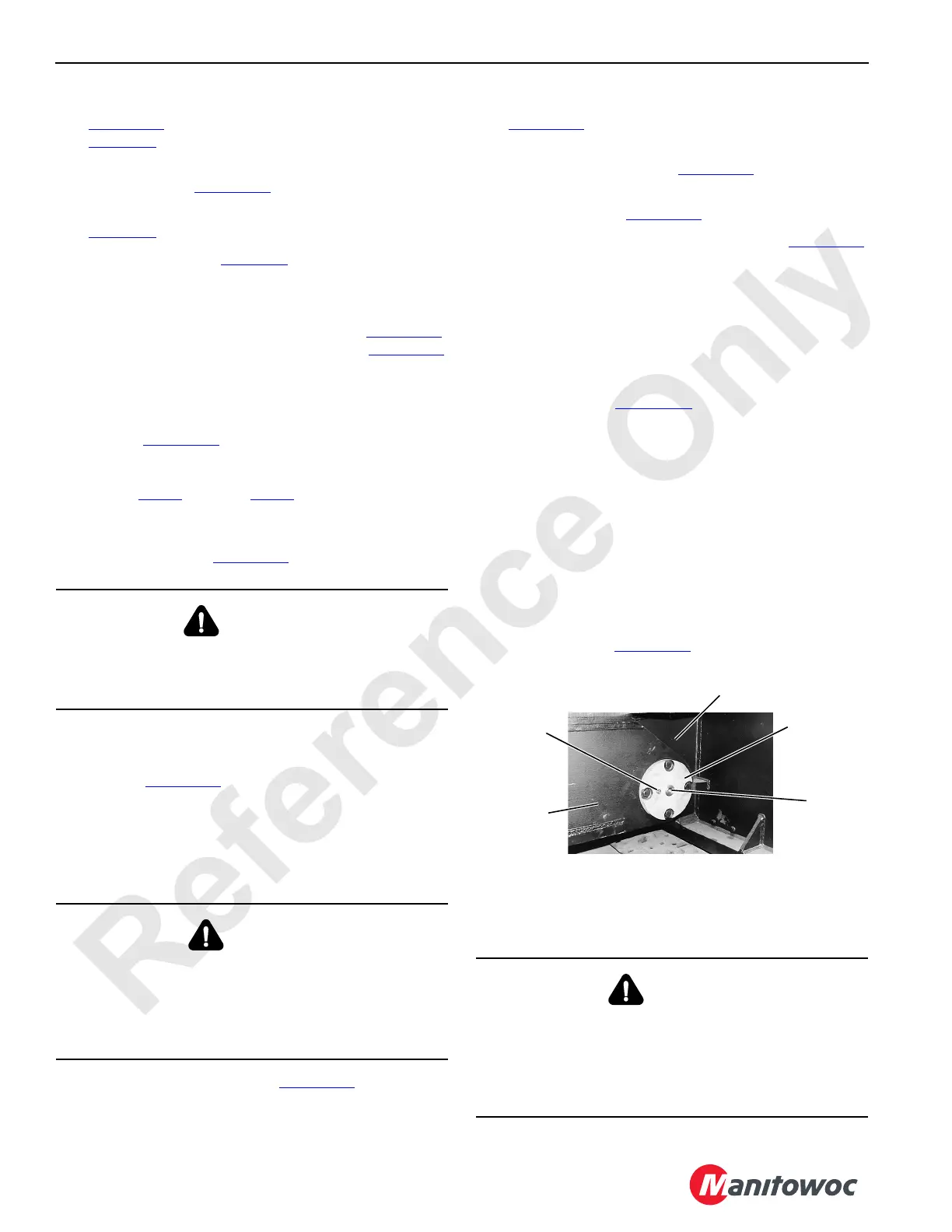

a. Pump grease into the grease fitting on the piston

cover plate (Figure 4-22

) while holding the crawler

frame pin switch at the disengage position for 10

seconds.

b. If the pin does not disengage, remove the plug from

the piston cover plate and measure the position of

the piston. When fully retracted, the piston is 25,7

cm (10-1/8 in) from the outside of the cover.

c. If the dimension is less than 25,7 cm (10-1/8 in)

remove the cover plate and, using a bar and

hammer, tap the piston until it is fully retracted

(check dimension). Replace the piston cover plate.

10. Lift the crawler. The crawler will tilt as it is lifted off the top

connecting pins (Figure 4-18

, View A).

11. Continue lifting the crawler. Stop before hitting the cab

support.

WARNING

Tipping Hazard!

Avoid possible injury. Level the assembly using a

carpenter’s level to avoid potential tipping.

DANGER

Rotating Drive Shaft Hazard!

The crawler drive shaft rotates at high speeds. To prevent

death or serious injury, do not attempt to disconnect the

drive shaft until the crane has been parked and the engine

has stopped.

DANGER

Falling Boom Hazard!

Avoid serious injury. The crane boom can collapse if not

properly lowered.

Carefully perform the following steps to properly lower the

boom and prevent it from falling suddenly.

FIGURE 4-22

Grease

Fitting

Carbody

Crawler Frame

Piston

Cover Plate

Plug

P619

Loading...

Loading...