Manitowoc Published 06-24-16, Control # 241-01 3-33

2250 OPERATOR MANUAL OPERATING CONTROLS AND PROCEDURES

PREPARING CRANE FOR OPERATION OPERATION

Engine Startup

See the Engine Manual for additional startup instructions

and precautions.

1. Unplug or turn off the engine block heater and any other

tank heaters that the crane is equipped with.

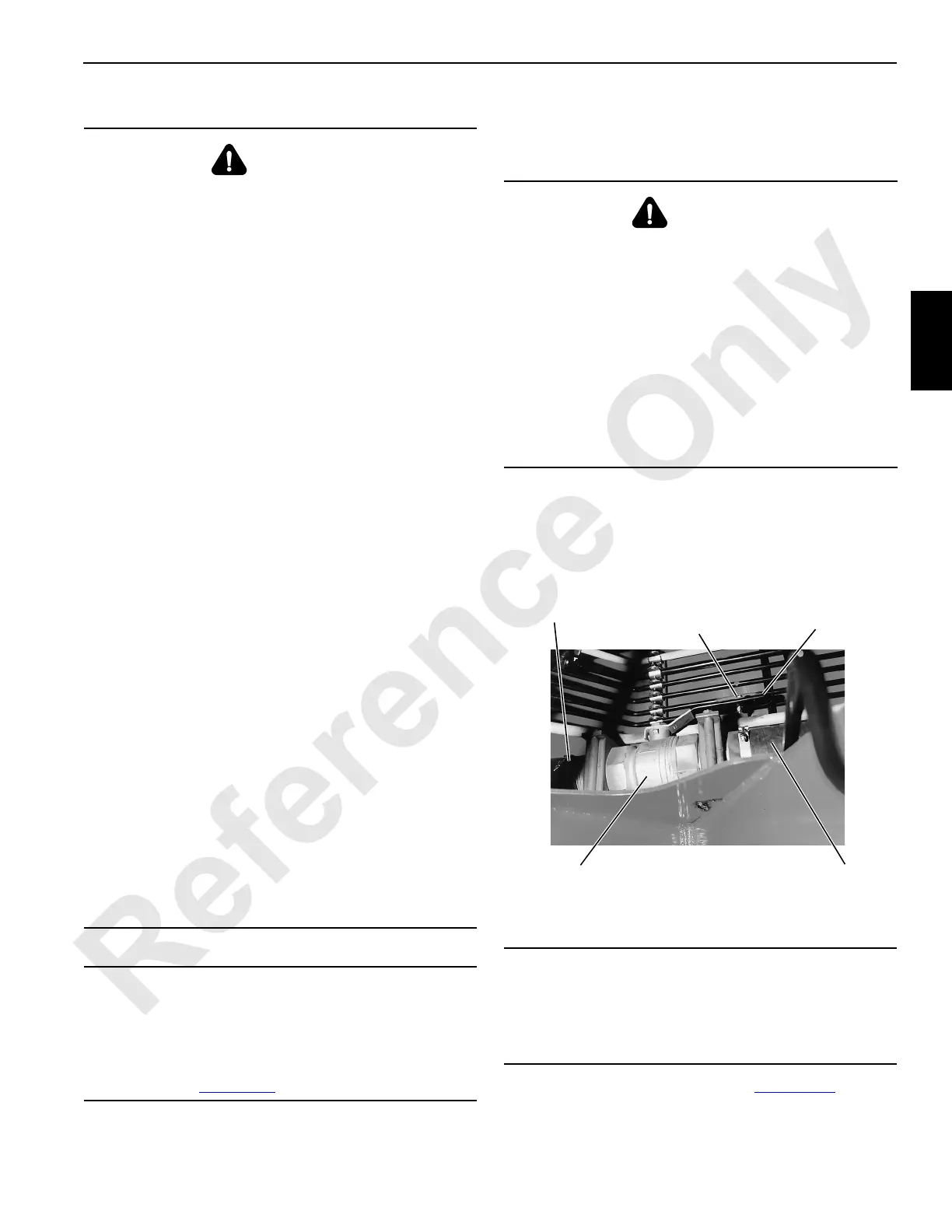

2. Open the hydraulic shut-off valve (Figure 3-14

).

WARNING

Read Capacity Charts!

Avoid serious injury or equipment damage. Failing to

comply with the capacity charts can result in tipping or

structural failure of the boom/luffing jib.

Do not attempt to operate the crane without first reading

and understanding the capacity charts.

The crane must be rigged and operated according to the

instructions given in the capacity charts and rigging

guides.

Unless otherwise specified in the capacity charts, all

crane operations must be performed with the crane level

to within one percent of grade. Otherwise, the crane could

tip.

Observe the minimum block weight requirement given on

the capacity charts.

Be aware when operating in those areas of the capacity

chart marked b, the weight of the backstay pendants can

pull the jib against the physical stops if the load block or

hook-and-weight ball is not heavy enough. This action will

result in sudden unexpected movement of the load.

Make sure the crawlers are blocked, if required per the

capacity chart, prior to raising and lowering the

attachment. Read and comply with the instructions in the

Crawler Blocking Diagram.

Do not operate the crane, which includes raising the boom

from ground level, if the wind exceeds the limits given in

the capacity charts. Contact your local weather station for

wind velocity.

Moving Load Hazard!

Avoid injuring personnel in the operating area! Sound the

horn to alert personnel that operation is about to begin.

The operator shall select the proper operating mode prior

to operation. Unexpected drum motion or improper limit

responses can result if the wrong mode is selected.

The limit bypass switch must be in the ACTIVATE

position, and all limits with which the crane is equipped

must be operational before operating the crane. See the

Service Manual for adjustment procedures.

CAUTION

Machinery Damage!

Before operating the crane at the start of each shift,

perform preventive maintenance checks and lubrication

services listed in your Operator Manual. Adjust the

operator’s seat (Figure 3-13

).

WARNING

Running Engine Hazard!

Avoid injuring personnel or equipment damage. A running

engine has the potential to sever limbs. Do not start the

engine until the following precautions are observed.

• Do not start the engine if a warning or out-of-order

sign is present at the start controls.

• Make sure all controls are off so the crane and load do

not move when the engine is started.

• Make sure all personnel are clear of the crane before

starting the engine. Sound the horn to alert personnel

that operation is about to begin.

CAUTION

Pump Damage!

Avoid damaging the pumps. The pumps could cavitate

and be damaged if the engine is started with the hydraulic

shut-off valves closed.

FIGURE 3-14

P779

Hydraulic Tank

Shut-off Valve

To Hydraulic

Tank

Handle Open

(pull towards you to

close)

To

Pumps

Install Bolt and Nut or

Padlock to Lock

Handle Open

View at Rear of Rotating Bed

Near Hydraulic Tank

Loading...

Loading...