Manitowoc Published 06-24-16, Control # 241-01 3-71

2250 OPERATOR MANUAL OPERATING CONTROLS AND PROCEDURES

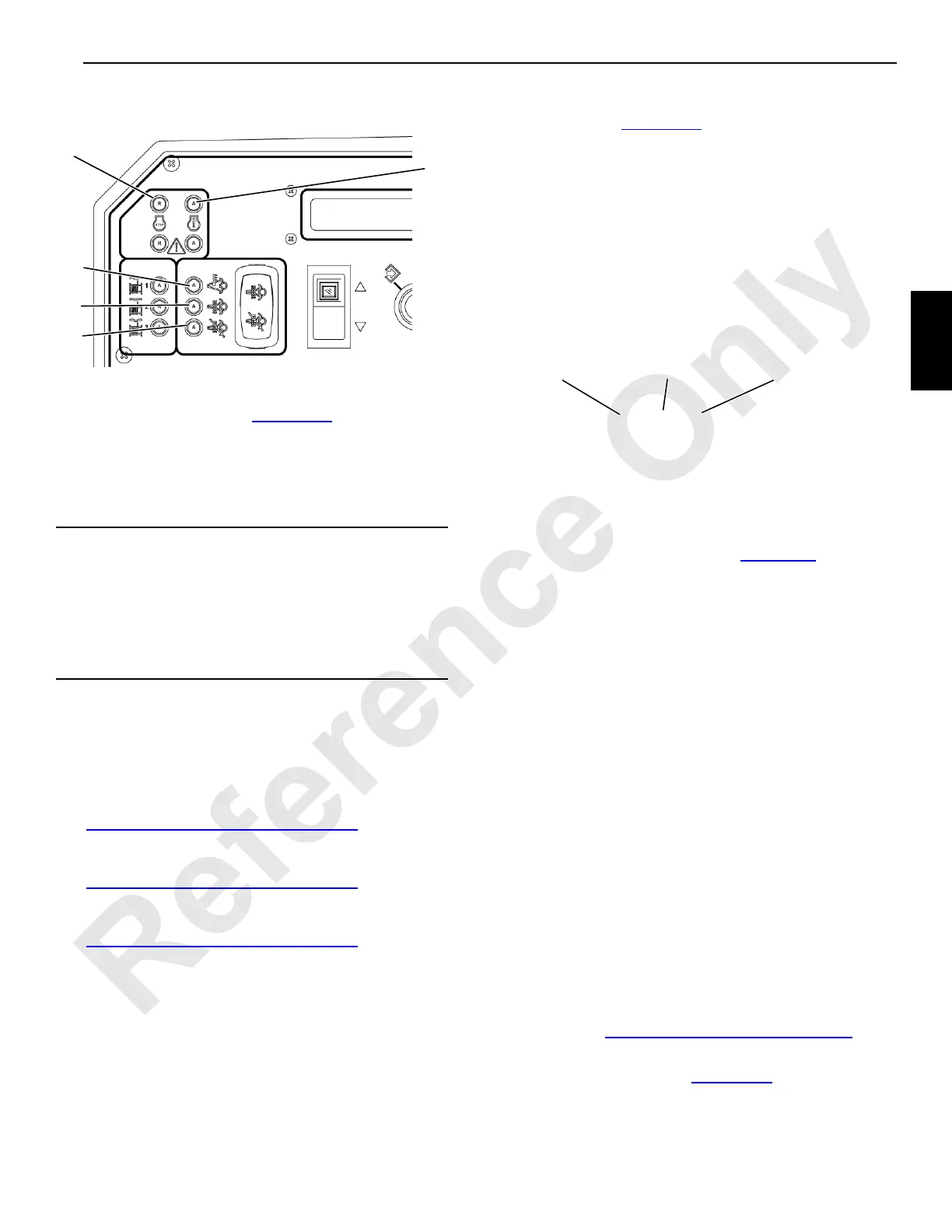

Diagnostic Lights

The engine diagnostic lights are mounted on the front

console in the operator’s cab (Figure 3-54

).

1—Engine Stop Light

The red Engine Stop light indicates the need to stop the

engine as soon as safely possible and correct the fault.

2—Engine Warning Light

The amber Engine Warning light indicates that the engine

can be run but the fault should be corrected as soon as

possible.

3—High Exhaust System Temperature

See A4—Exhaust System Lights on page 3-14 for details.

4—DPF Regeneration Active

See A4—Exhaust System Lights on page 3-14 for details.

5—DPF Regeneration Inhibited

See A4—Exhaust System Lights on page 3-14 for details.

Engine Diagnostics

The engine has two diagnostic modes, as follows:

• Off-board diagnostics—This mode requires special

hardware and software from the engine manufacturer.

• On-board diagnostics—This mode has warning lights to

alert the operator to engine problems during operation

(engine running) and has fault codes to identify specific

engine problems (Figure 3-54

).

To identify active faults, proceed as follows:

1. Stop the engine.

2. Move the ignition switch to the RUN position.

3. Move the hand throttle from LOW speed to HIGH speed

and back to LOW speed three times within five seconds.

If no active faults exist, the amber Engine Warning light

and red Engine Stop light come on but do not flash.

If there is an active fault, the amber Engine Warning light

flashes to indicate that a fault code will be flashed.

4. After another two-second pause, the red diagnostic light

flashes the fault code.

After a two-second pause, the same fault code flashes a

second time before advancing to the next fault code.

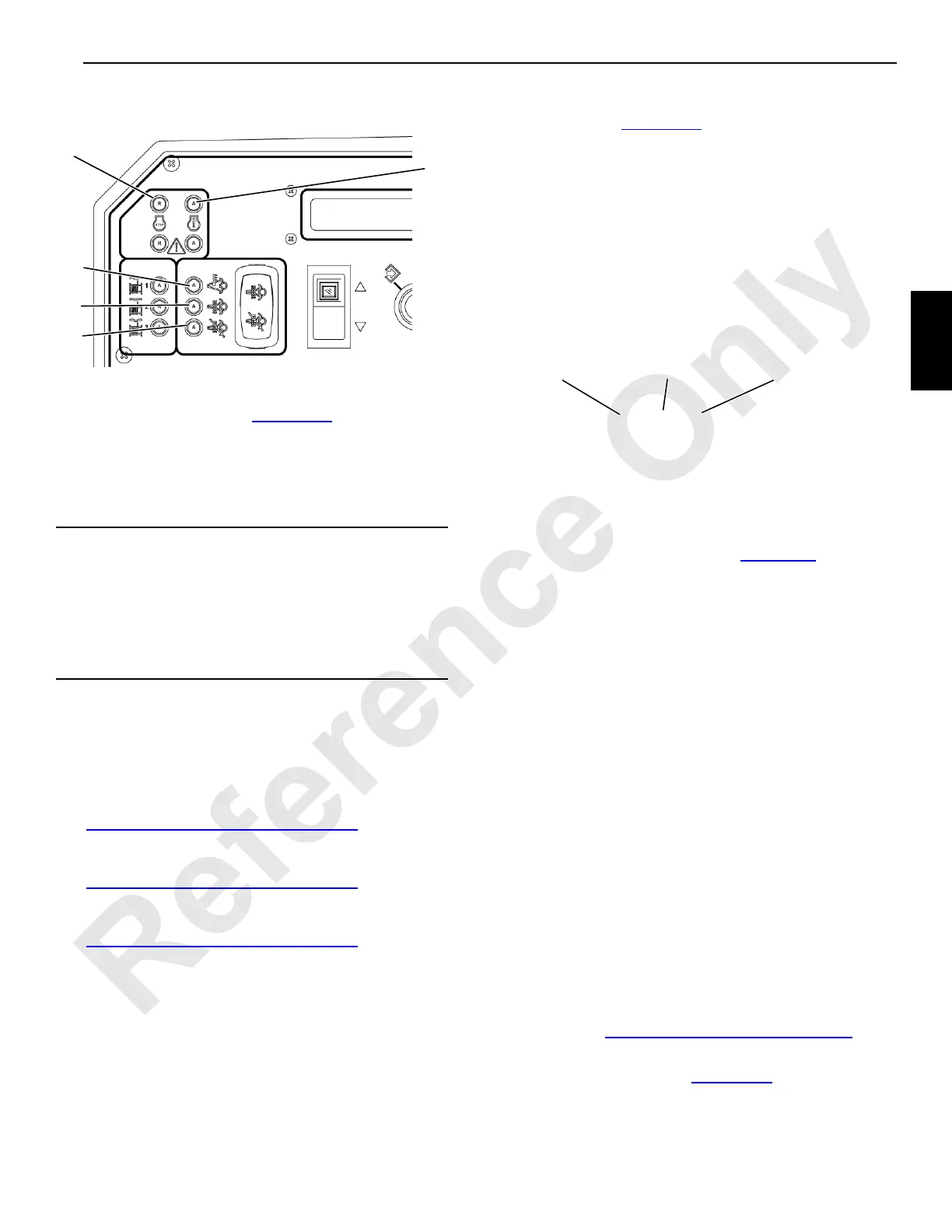

NOTE: To decipher the fault code, see Figure 3-55

.

5. See the engine manufacturer’s manual for a list of fault

codes.

DRUM INTERLOCK

General

The drum interlock physically connects both load drums on a

split drum shaft to allow single load line operation with dual

brakes either in the Free Fall or the Full Power mode.

With drum interlock, both drums are controlled by one load

drum control handle and one drum working brake pedal.

NOTE: Drum interlock cannot be used on three-drum

cranes.

Free Fall Mode

Dual working brakes, in effect, double the braking surface,

which results in less brake heat and wear.

Use drum interlock in the Free Fall mode for a concrete

bucket and similar operations where the load is continually

lowered long distances on the drum working brake.

Drum interlock in the Free Fall mode requires installing a

drive lug between the drums and rerouting the drum working

brake air lines. See Installing Drum Interlock on page 3-72

.

For drum interlock operation in the Free Fall mode, reroute

the drum working brake air lines (Figure 3-58

).

Operate the drums in Free Fall mode as follows:

CAUTION

Engine Damage!

Permanent damage can occur if the engine is run while

the red Engine Stop light is on. Do not run the engine until

the fault is corrected. If possible, lower the lifted loads and

then stop the engine as soon as possible when the red

Engine Stop light comes on.

FIGURE 3-55

3 1 9

3 Flashes—PAUSE—1 Flash—PAUSE—9 Flashes

Fault Code =

Loading...

Loading...