Manitowoc Published 06-24-16, Control # 241-01 3-73

2250 OPERATOR MANUAL OPERATING CONTROLS AND PROCEDURES

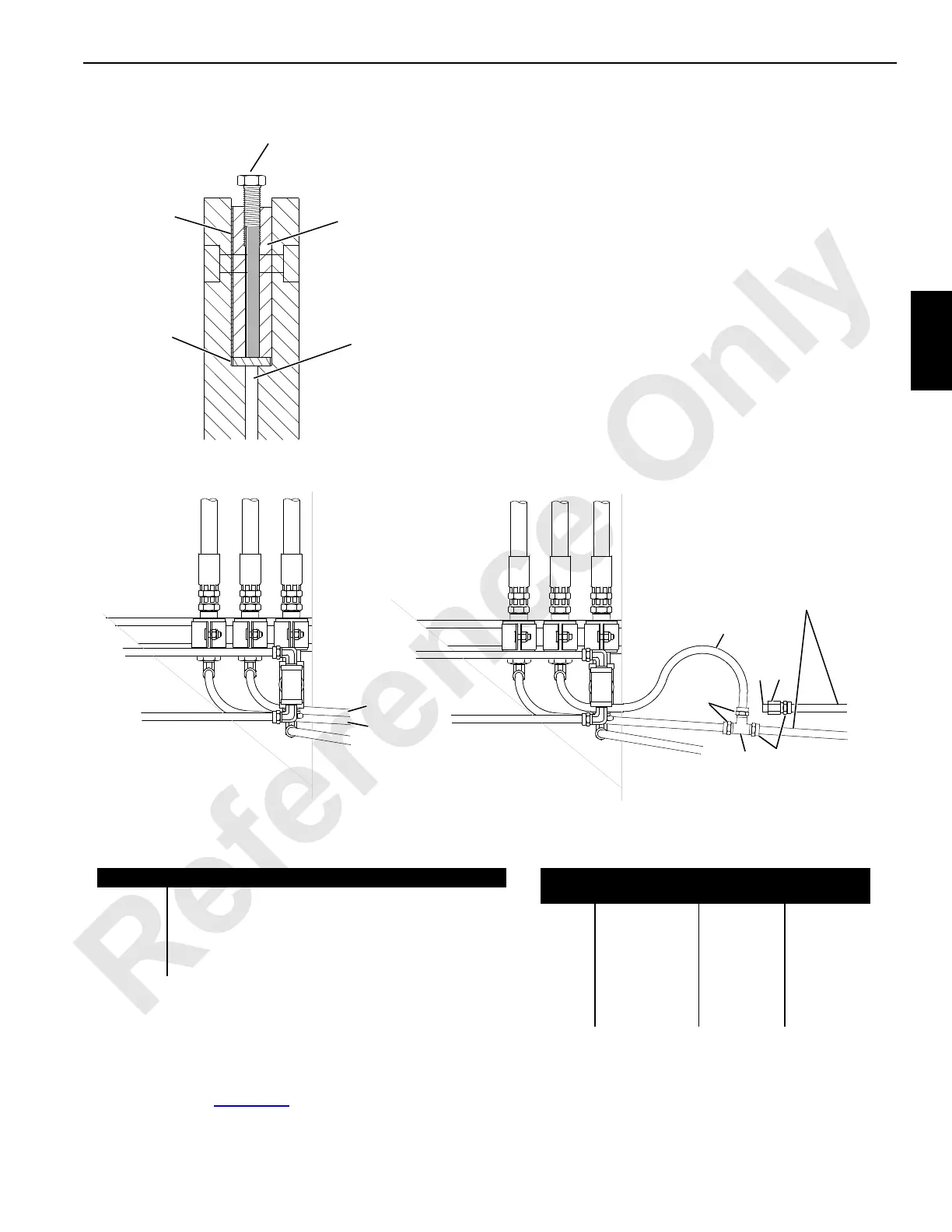

5. Remove the air fittings and reroute the air lines so they

are connected (Figure 3-58

, View A).

6. Make sure all fittings are tight to prevent air leaks.

7. Install the load line on another drum if necessary.

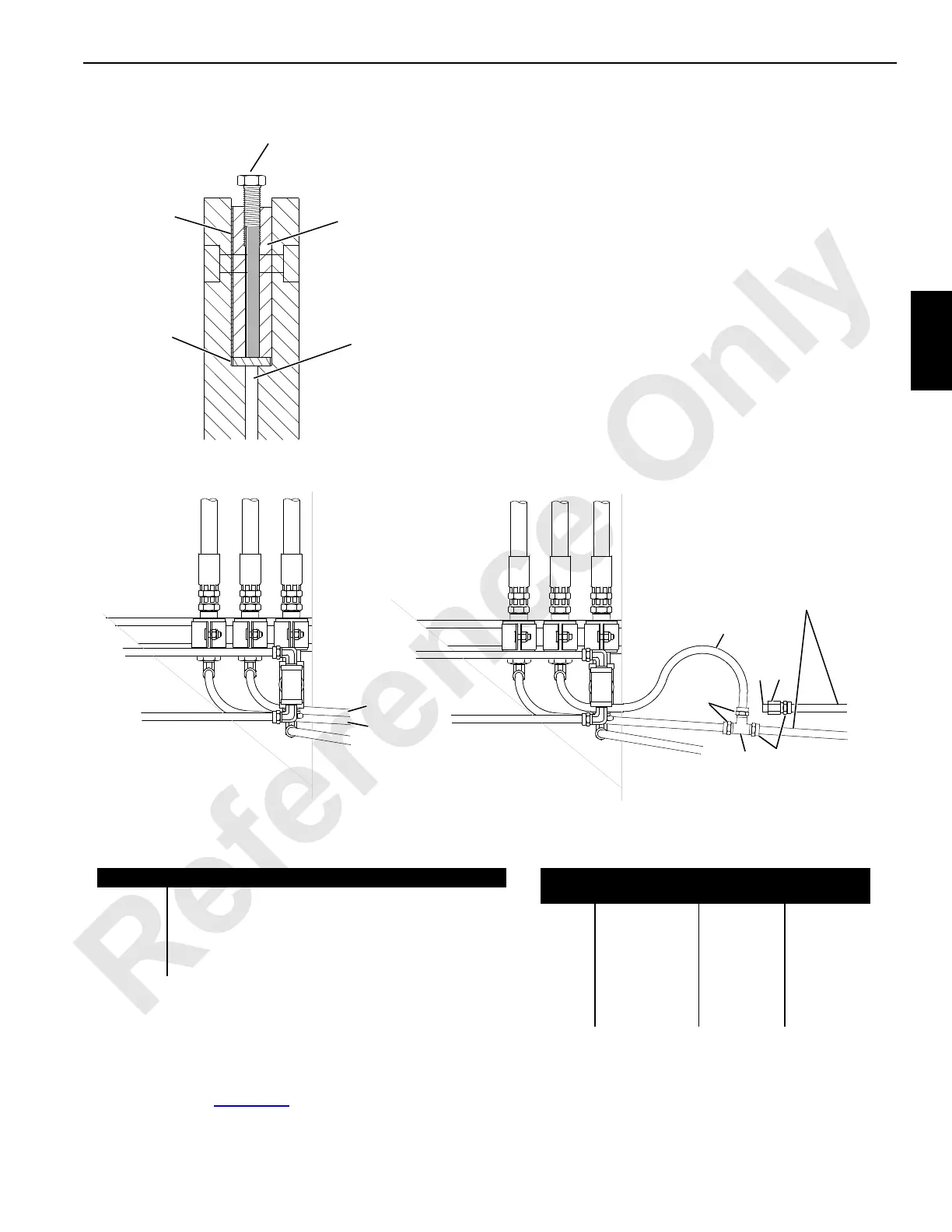

FIGURE 3-57

A583

1/2 inch - 13 UNC Bolt (50,8 mm [2 in])—Turn

Bolt Clockwise to Jack Drive Lug Out of Keyways

Shims

Flat Bar

9,5 mm (3/8 in) Diameter

Bar 101,60 mm (4 in) Long

Drive Lug

Drive Lug Removal

FIGURE 3-58

Air Line Identification

Air Line Identification

A Delivery Air to Right Drum Working Brake Chamber

B Delivery Air to Left Drum Working Brake Chamber

C Jumper

M1 Supply Air to Right Drum Working Brake Treadle Valve

M2 Supply Air to Left Drum Working Brake Treadle Valve

Fitting Identification for 3/8 inch O.D. Air Line

Item Description MCC

Number

Quantity

1 Tee 429629 1

2 Ferrule 429627 4

3 Nut 429628 4

4 Female

Connector

429820 1

5 Plug 571721 1

C Air Line 486056 As Required

DRUM WORKING BRAKE AIR PIPING

BA

A

B

M2

M1

BA

2

3

C

54

A

B

2

3

1

M2

M1

A586

View A

Without Drum Interlock

View B

Drum Interlock Installed with

Left Drum Brake Pedal Active

Reverse this Piping

to Make Right Drum

Brake Pedal Active

Loading...

Loading...