OPERATING PROCEDURES TMS9000-2 OPERATOR MANUAL

4-56

Published 02-21-2019, Control # 611-05

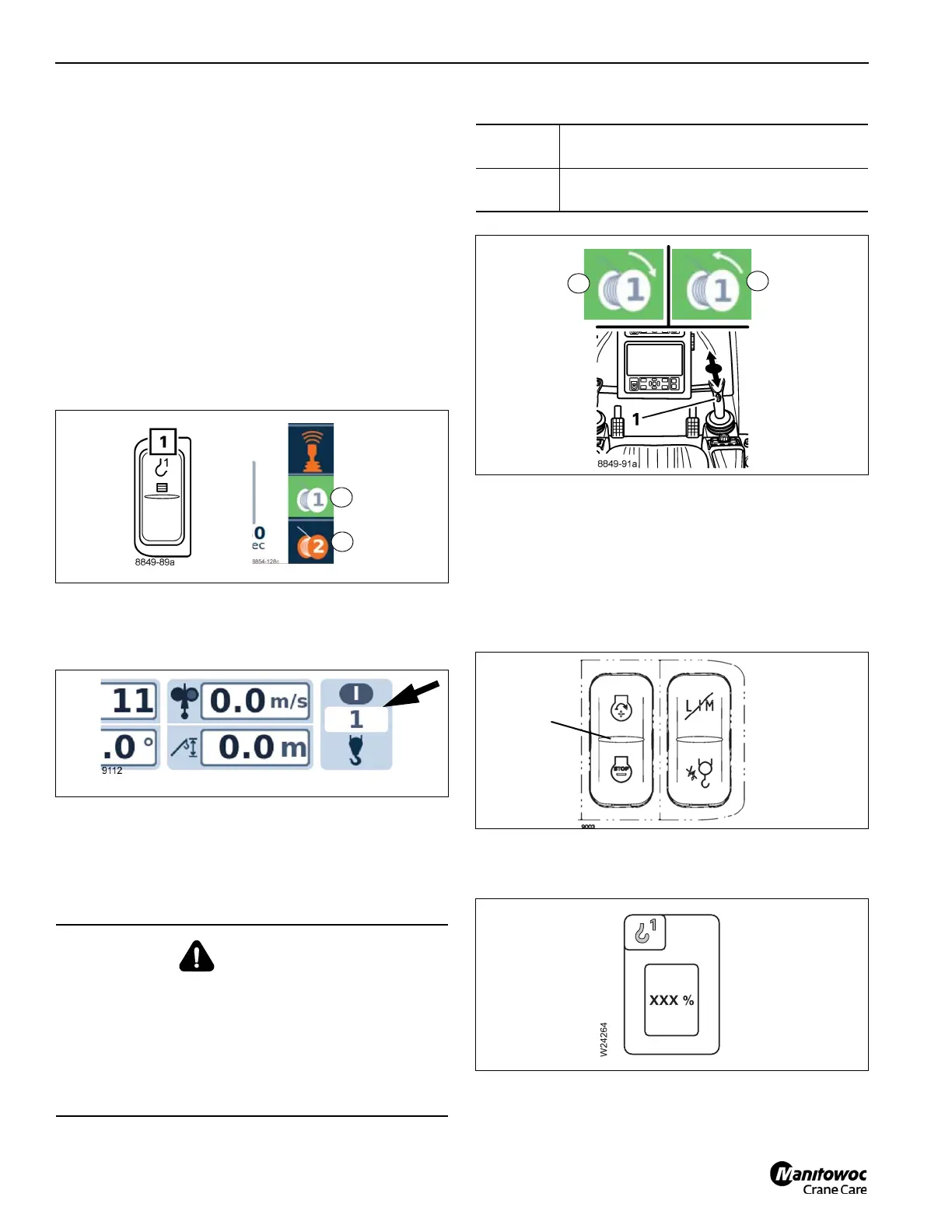

Switching on the main hoist

After the ignition is switched on, all of the power units will be

switched off and the lamps in the corresponding buttons will

light up only dimly.

• Check whether the auxiliary hoist is switched off and

therefore secured against unintentional operation.

NOTE: Be aware that the auxiliary hoist could two-block

when operating the main hoist.

- Symbol (3, Figure 4-86) must be red.

• Press the button on the right armrest (1, Figure 4-86)

once.

- Symbol (2) is green when the main hoist is switched

on.

• Check that the current reeving (Figure 4-87) of the main

hoist is displayed, e.g. 1. Correct the reeving if

necessary, refer to Entering the reeving, page 4-48.

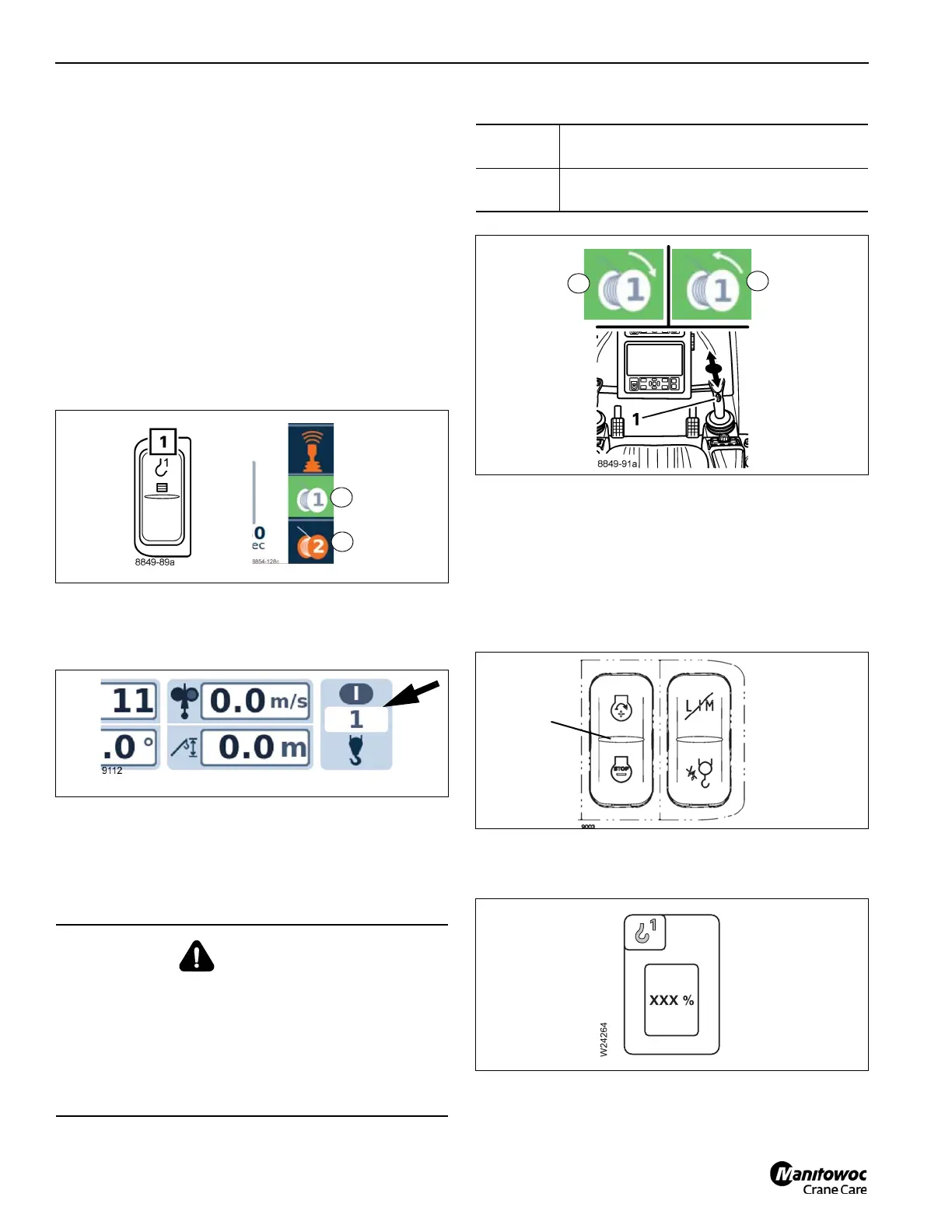

Lifting and lowering

You can adjust the sensitivity of the control levers to suit the

operating conditions, refer to Setting the characteristic

curves for the control levers, page 4-84.

When the hoist drum is turning, you will notice a pulse on the

rotation indicator (1, Figure 4-88).

You can regulate the speed by moving the control lever or

changing the engine speed.

You can set the desired engine speed (idling speed) with

button (1, Figure 4-89), refer to Engine Idle Increment/

Decrement Switch, page 3-7.

You can limit the maximum hoist speed (Figure 4-90), refer

to Limiting the power unit speeds, page 4-85.

You can switch on high-speed mode for a higher speed

(Figure 4-91), refer to High-speed mode, page 4-80.

WARNING

Rope Damage Hazard!

Use of hookblocks that do not have sufficient overhaul

weight could result in spooling problems causing damage

to the rope. Death or Serious injury could occur if the rope

breaks. Always ensure that the overhaul weight is

sufficient to keep tension on the rope even when no load

is being lifted.

8854-128c

FIGURE 4-86

8849-89a

2

3

Raising:

Pull the control lever to the rear – symbol (3,

Figure 4-88) is displayed.

Lowering:

Pull the control lever to the front – symbol (2)

is displayed.

Loading...

Loading...