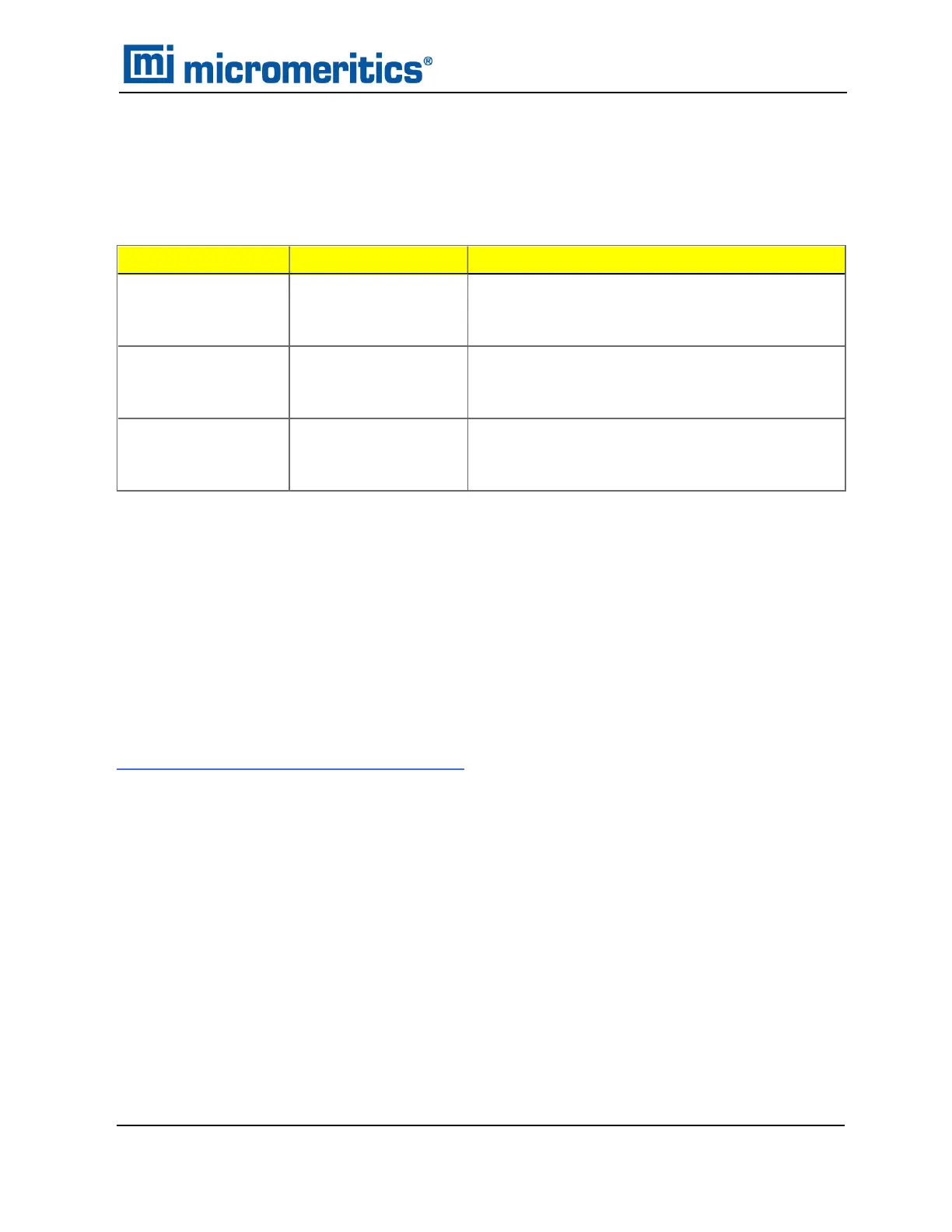

7. Click each tab across the top of the window and look for a reading of Passed. A Passed

reading indicates all valves are in a proper state for operation. If any test shows a Failed

reading, refer to the following table to help determine the location of the gas leak.

Tab

Test If Failed status, then...

Gas Line to Inlet

Port [n]

Test 1

Gas Line to Gas Cylin-

der Test

This test will show a reading of Failed if any of the

other tabs has a Failed reading. Correct the

failed connection and rerun the test.

Gas Line to Inlet

Port [n]

Test 2

Gas Line to Isolation

Valve Test

Check for a leak between the gas line and the

isolation valve. Correct the problem and rerun

the test.

Gas Line to Inlet

Port [n]

Test 3

Isolation Valve To

Cylinder Leak Rate

Check for a leak between the isolation valve and

the gas cylinder. Correct the problem and rerun

the test.

Corrective Action

If a test reports as failed, one or more valves is not in the proper position. Set the valves, then

ensure the appropriate pressure is displayed on the low pressure gauge.

If re-running the test, close the gas cylinder valve before starting the test.

1. Click Close to close the test report. Click Close again to close the test.

2. Repeat steps 1 through 8 for each gas line attached to the analyzer.

ENABLE MANUAL CONTROL

Unit [n] > Enable Manual Control

Show Instrument Schematic on page2 - 20

Use Enable Manual Control to enable the manual control of certain system valves and pump com-

ponents on the analyzer schematic. When this option is enabled, a checkmark appears to the left

of Unit [n] > Enable Manual Control. If the analyzer schematic is not immediately visible, go to

Unit [n] > Show Instrument Schematic.

Enable Manual Control

TriStar II Plus Operator Manual

303-42800-01 (Rev M ) — Sep 2023

11 - 11

Loading...

Loading...