11 Troubleshooting

PREVENTIVE MAINTENANCE

Perform the following preventive maintenance procedures to keep the analyzer operating at peak

performance. Micromeritics also recommends that preventive maintenance procedures and

calibration be performed by a Micromeritics Service Representative every 12 months.

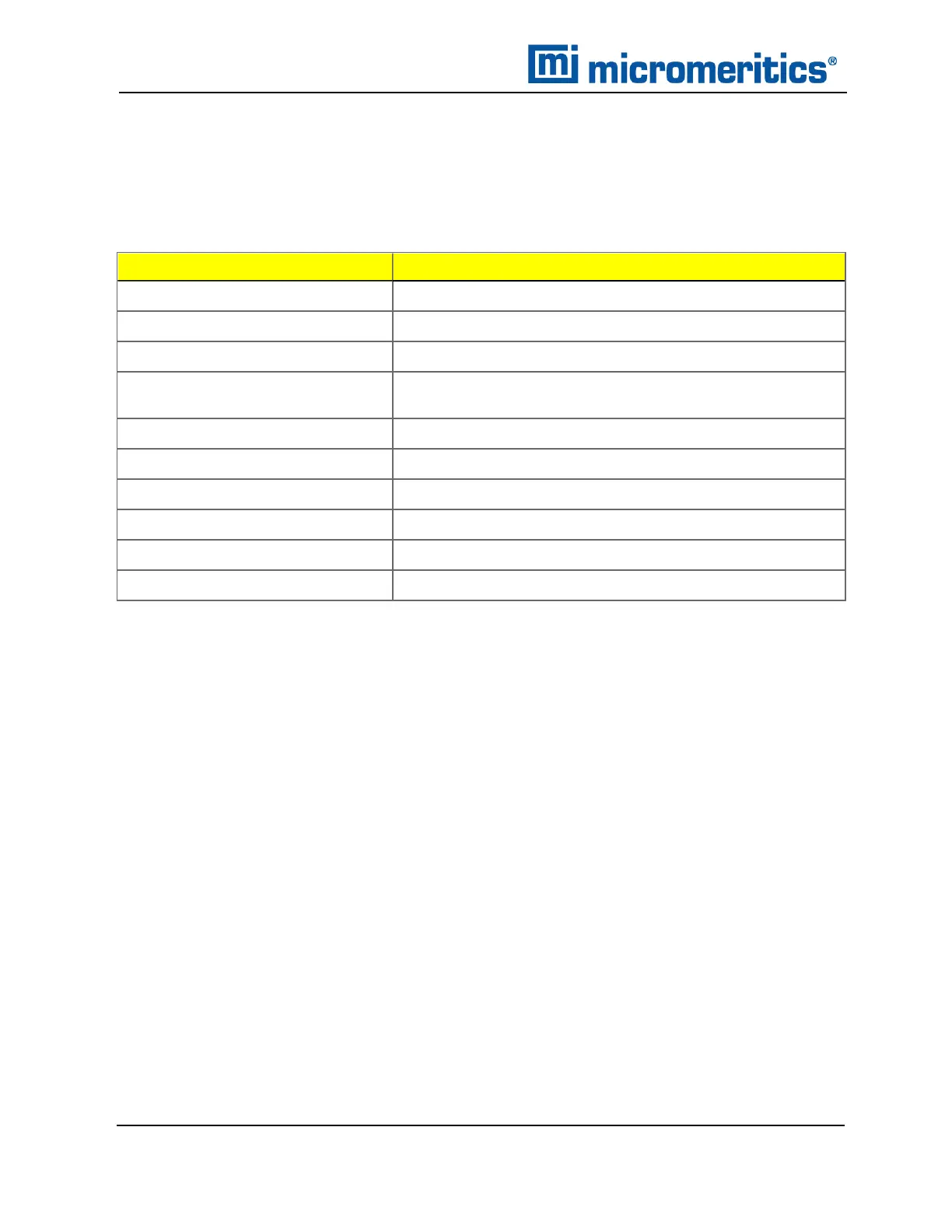

Maintenance Required

Frequency

Alumina in vapor oil traps *

Replace as required.

Analyzer exterior

Clean as required or every 3 to 6 months.

Dewar

Check and clean weekly.

Diaphragm vacuum pump **

If an oil-free pump is used, replace diaphragm(s) every 12

months.

Dry forepumps

As required or every 24 months.

Port filters and O-rings

Replace every 3 to 6 months.

Sample tube O-ring

Replace as required or every 3 to 6 months.

Test for leaks

As required or every 12 months.

Vacuum pump exhaust filter

Replace as required or every 12 months.

Vacuum pump fluid *

Inspect and change as required or every 3 to 6 months.

*Oil sealed vacuum pumps only.

** For oil-free pumps only: After 12 to 18 months of operation, the diaphragm(s) in the pump will

wear out and the pump becomes completely inoperable. To prevent instrument downtime due

to an inoperable pump, it is recommend that the diaphragm(s) be replaced by a Micromeritics

Service Representative every 12 months.

11 - 14

TriStar II Plus Operator Manual

303-42800-01 (Rev M ) — Sep 2023

Loading...

Loading...