10-2 M68020 USER’S MANUAL MOTOROLA

Solving Equations (10-1) and (10-2) for K gives:

K = P

D

• (T

A

+ 273°C) + θ

JA

•P

D

2

(10-3)

where K is a constant pertaining to the particular part. K can be determined from equation

(10-3) by measuring P

D

(at thermal equilibrium) for a known T

A

. Using this value of K, the

values of P

D

and T

J

can be obtained by solving equations (10-1) and (10-2) iteratively for

any value of T

A

.

The total thermal resistance of a package (

θ

JA

) can be separated into two components,

θ

JC

and θ

CA

. θ

JC

represents the barrier to heat flow from the semiconductor junction to

the package (case) surface, and θ

CA

represents the barrier to heat flow from the case to

the ambient air. These terms are related by the equation:

θ

JA

=θ

JC

+

θ

CA

(10-4)

θ

JC

is device related and cannot be influenced by the user. However, θ

CA

is user

dependent and can be minimized by such thermal management techniques as heat sinks,

forced air cooling, and use of thermal convection to increase air flow over the device.

Thus, good thermal design on the part of the user can significantly reduce θ

CA

so that θ

JA

approximately equals θ

JC

. Substitution of θ

JC

for θ

JA

in equation (10-1) results in a lower

semiconductor junction temperature.

10.2.1 MC68020 Thermal Characteristics and

DC Electrical Characteristics

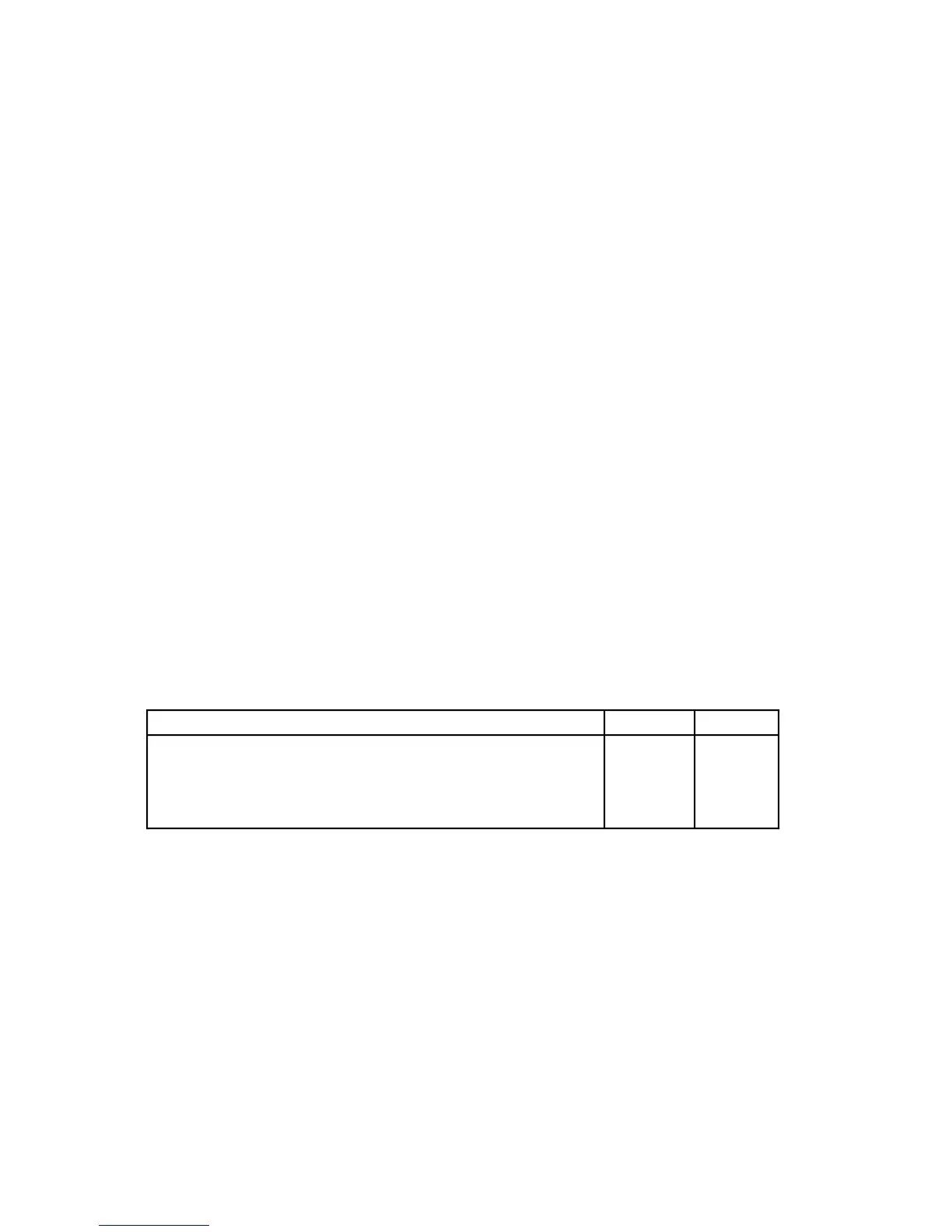

MC68020 Thermal Resistance (°C/W)

The following table provides thermal resistance characteristics for junction to ambient and

junction to case for the MC68020 packages with natural convection and no heatsink.

Characteristic—Natural Convection and No Heatsink θ

JA

θ

JC

Thermal Resistance

PGA Package (RC Suffix)

PPGA Package (RP Suffix)

CQFP Package (FE Suffix)

PQFP Package (FC Suffix)

26

32

46

42

3

10

15

20

Resistance is to bottom center (pin side) of case for PGA and PPGA packages, top center of case

for CQFP and PQFP packages.

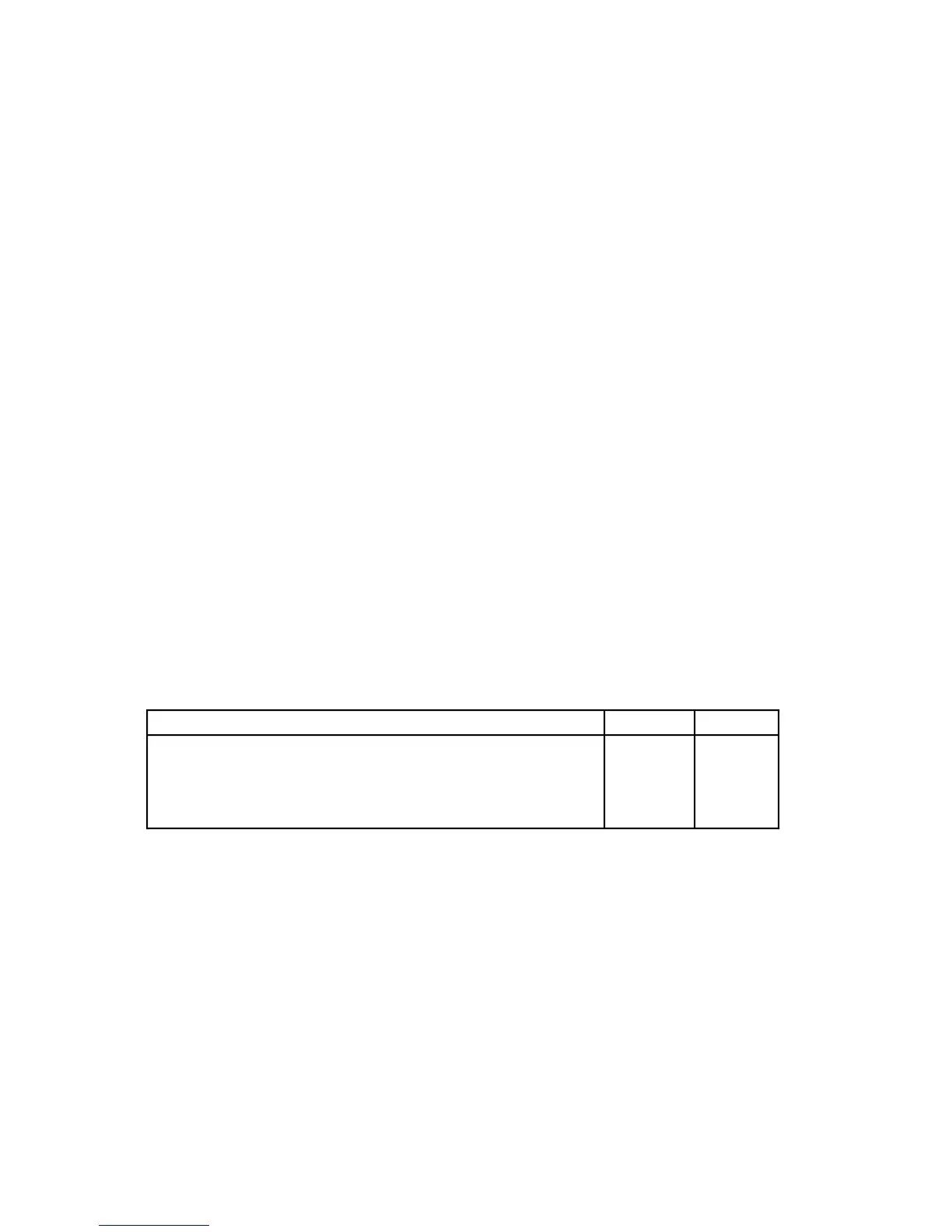

MC68020 CQFP Package

Table 10-1 provides typical and worst case thermal characteristics for the MC68020

CQFP package both with and without a heatsink. The heatsink used is black anodized

aluminum alloy, 0.72"x0.75"x0.6" high with an omnidirectional 5x6 array of fins.

Attachment was made using Epolite 6400 one part epoxy.

Loading...

Loading...