Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 3-40 P/N 196515 (Revision A)

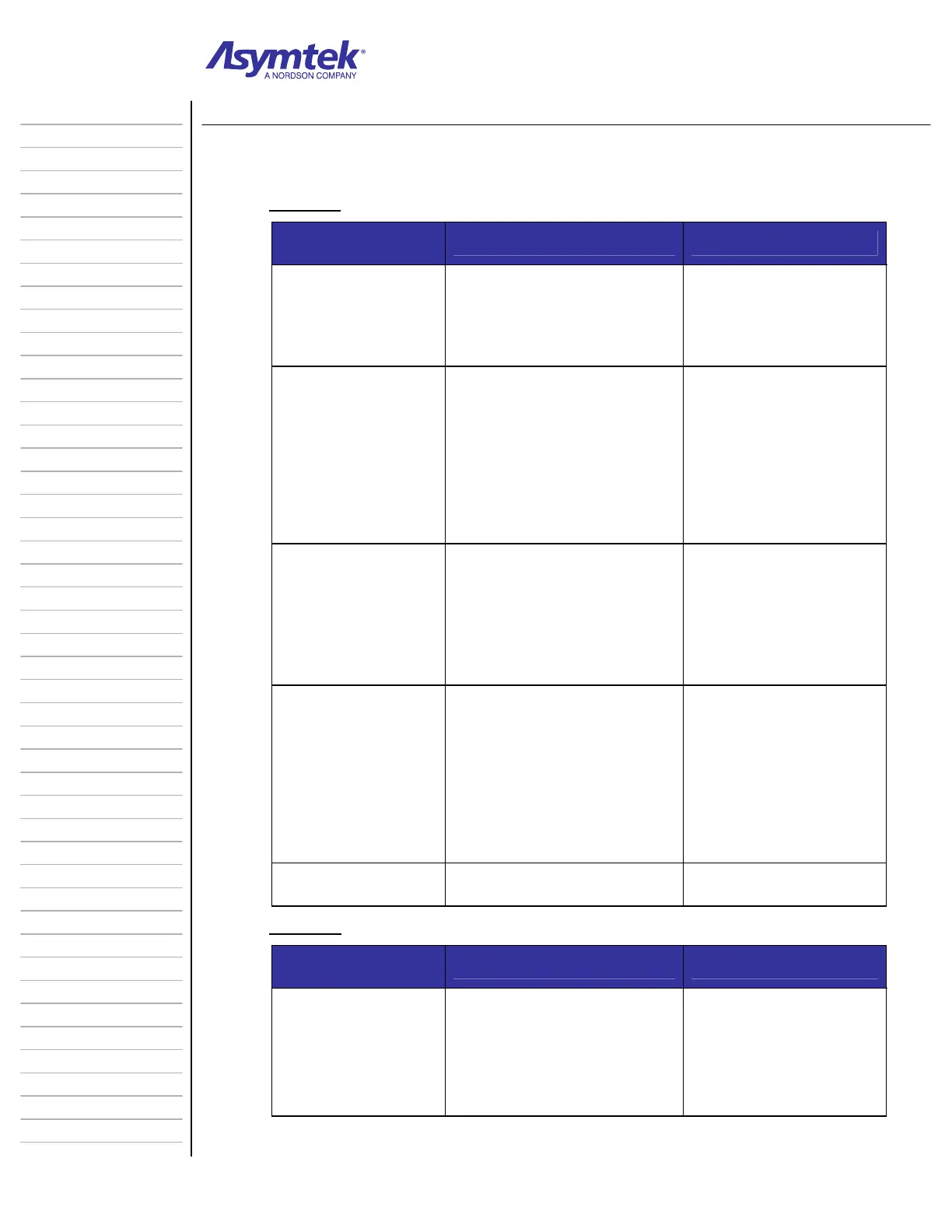

Information Sheet 3-8-1

Valve/Pump Maintenance

A. DP-3000

Maintenance

Procedure

Recommended Frequency Instructions

Clean pumping

chamber

Before the expiration of the

pot life of the fluid.

Immediately when changing

from one type of fluid to

another.

See Exercise Sheet 3-8-2

Page 3-44

Replace stopcock

Before the expiration of the

pot life of the fluid.

Immediately when changing

from one type of fluid to

another.

Note: Dispensing with

abrasive materials may

require the stopcock to be

replaced more frequently.

See Exercise Sheet 3-8-2

Page 3-44

Replace seals and O-

rings inside the

pumping chamber

Once every 72 hours of

operating usage.

Immediately if you are

changing from one type of

fluid to another.

If using short pot life

material, replace daily.

See Exercise Sheet 3-8-2

Page 3-44

Clean exterior and

interior exposed

surfaces of the pump

Once every 72 hours of

operating usage.

Immediately if you are

changing from one type of

fluid to another.

If material has short pot life,

clean surfaces when

cleaning the pumping

chamber.

Use a clean, soft cloth and

isopropyl alcohol (IPA) to

remove any residual fluid

and dirt from all areas of

the pump.

Grease the Lead

Screw

Once each quarter.

See DP-3000 Installation

and Service Manual

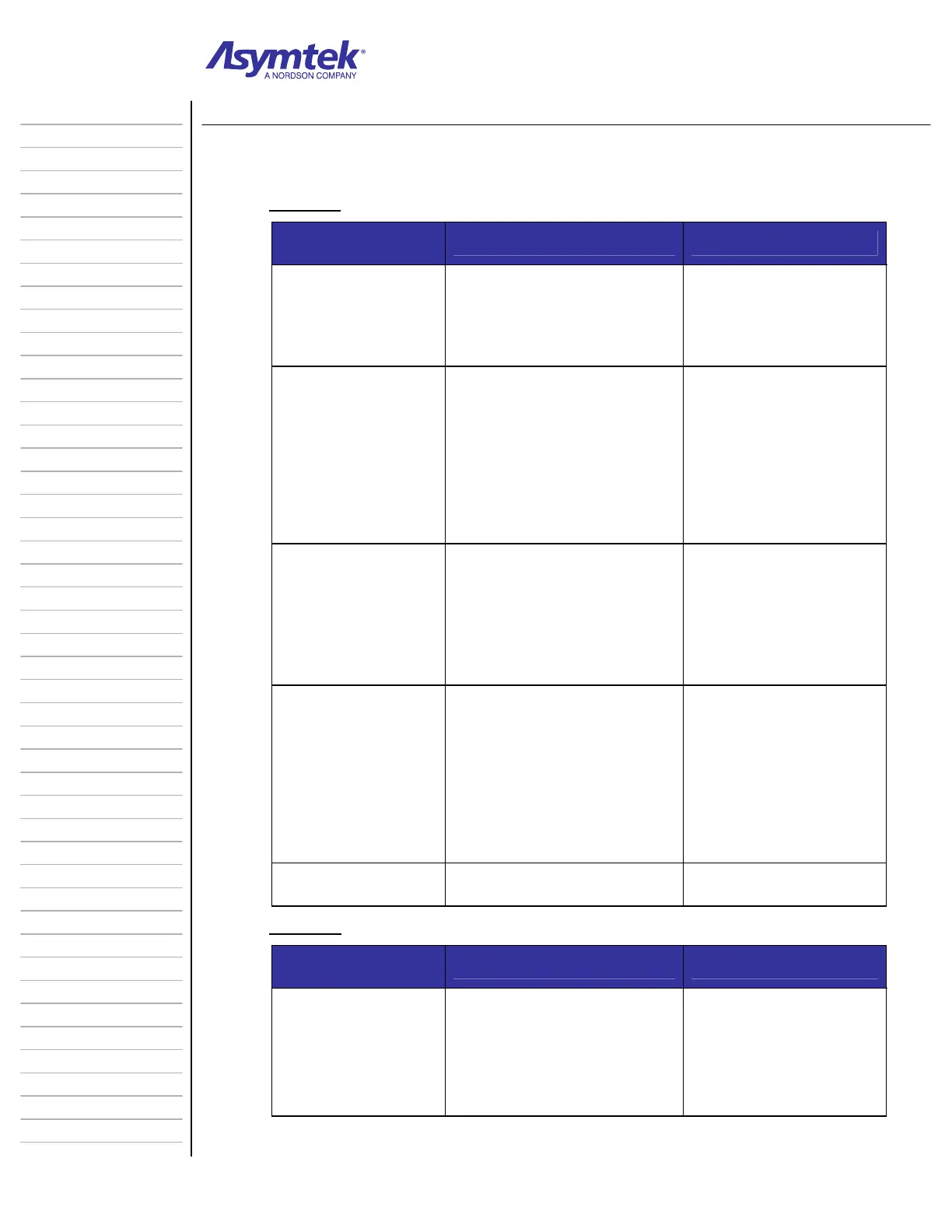

B. DV-7000

Maintenance

Procedure

Recommended Frequency Instructions

Clean exterior and

interior exposed

surfaces of the pump

Clean daily.

Clean before using new

fluid.

Clean immediately after

using curable material.

If needle tip is clogged

See Exercise Sheet 3-8-5

on page 3-50

Loading...

Loading...