Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-103 P/N 196515 (Revision A)

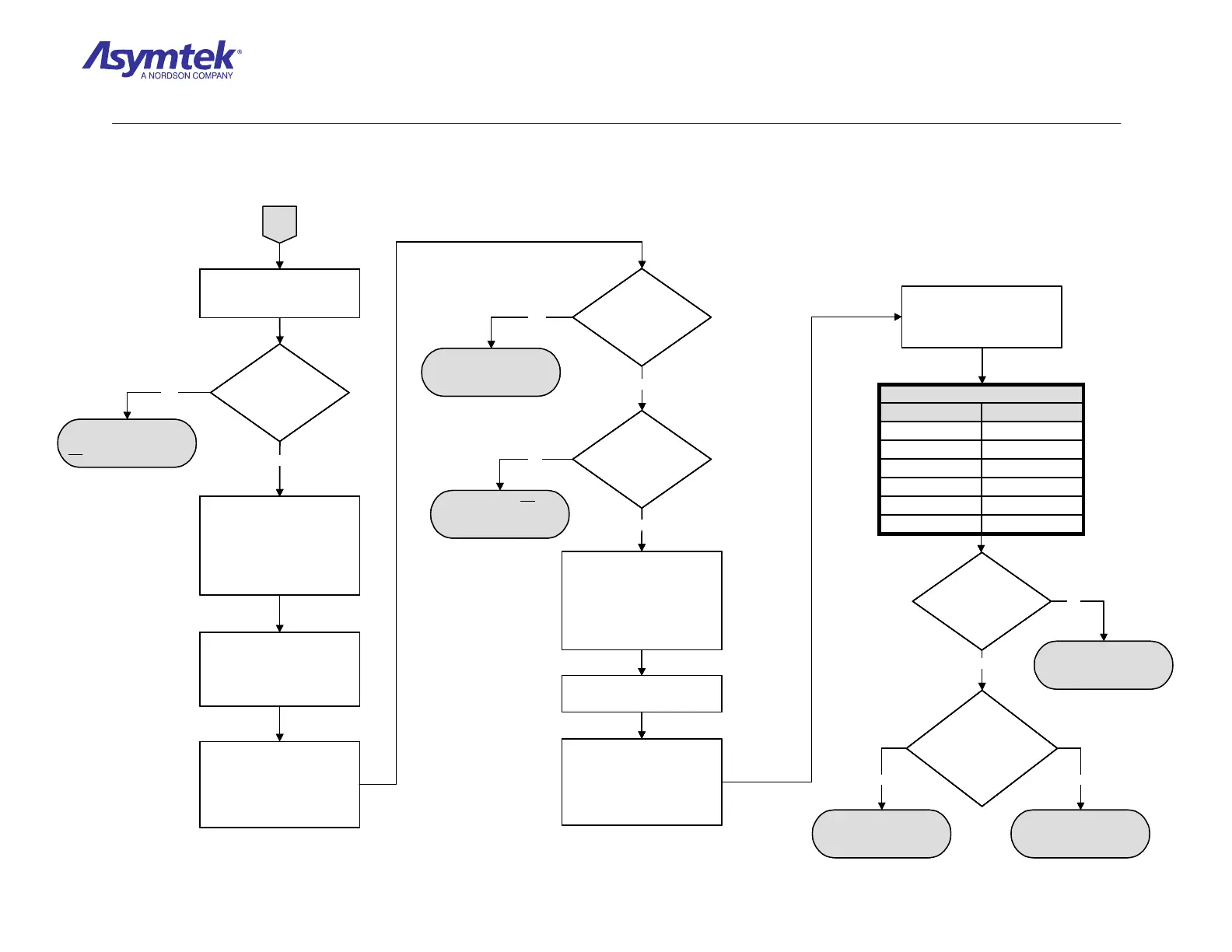

Stop! The Board Sensor is

not

root cause of the fault

Is bit changing

in Conveyor I/O

screen display when

workpiece is passed

beneath it?

In FmNT, observe the

Conveyor I/O screen display

on the Monitor.

A

Exit FmNT, shut down

Windows NT, press black

OFF (0) button on the

Operator’s Console, switch

Main Circuit Breaker to OFF

(0), and disconnect Power

Cable from facility outlet

Exchange the Board Sensor

Connector with another

Board Sensor Connector at

the Conveyor Interconnect

PWA.

Connect the Power Cable to

the facility outlet, switch Main

Circuit Breaker to ON (I)

position, press the green ON

(I) button on the Operator’s

Console, and enter FmNT.

Did the error follow

the exchanged Board

Sensor Connector?

Did the error move

to the other Board

Sensor?

Exit FmNT, shut down

Windows NT, press black

OFF (0) button on the

Operator’s Console, switch

Main Circuit Breaker to OFF

(0), and disconnect Power

Cable from facility outlet

Remove side cover from

Conveyor Controller.

Connect the Power Cable to

the facility outlet, switch Main

Circuit Breaker to ON (I)

position, press the green ON

(I) button on the Operator’s

Console, and enter FmNT.

Measure signal between pin

and ground on the Conveyor

Interface PWA at the

locations specified in Table 1.

U6, Pin 1Sensor Right B

U4, Pin 7Sensor Center B

U4, Pin 3Sensor Left B

U6, Pin 3Sensor Right A

U4, Pin 5Sensor Center A

U4, Pin 1Sensor Left A

Pin LocationSensor

Table 1

When the Board

Sensor is unblocked, is

reading 24 VDC?

When Board

Sensor is blocked,

does Conveyor Controller

toggle from high (24

VDC) to low (approx.

0 VDC)?

Conveyor Controller

(P/N 62-1677-00 for

X1020 or 62-1676-00 for

X1010) has failed.

Go to Conveyor Signals

Cable Verification.

Board Sensor has failed.

Board Sensor is not root

cause of fault. If fault

reoccurs, contact Asymtek

Technical Support

Conveyor Controller

(P/N 62-1677-00 for

X1020 or 62-1676-00 for

X1010) has failed.

Yes

No

Yes

No

Yes

No

Yes

No

Yes No

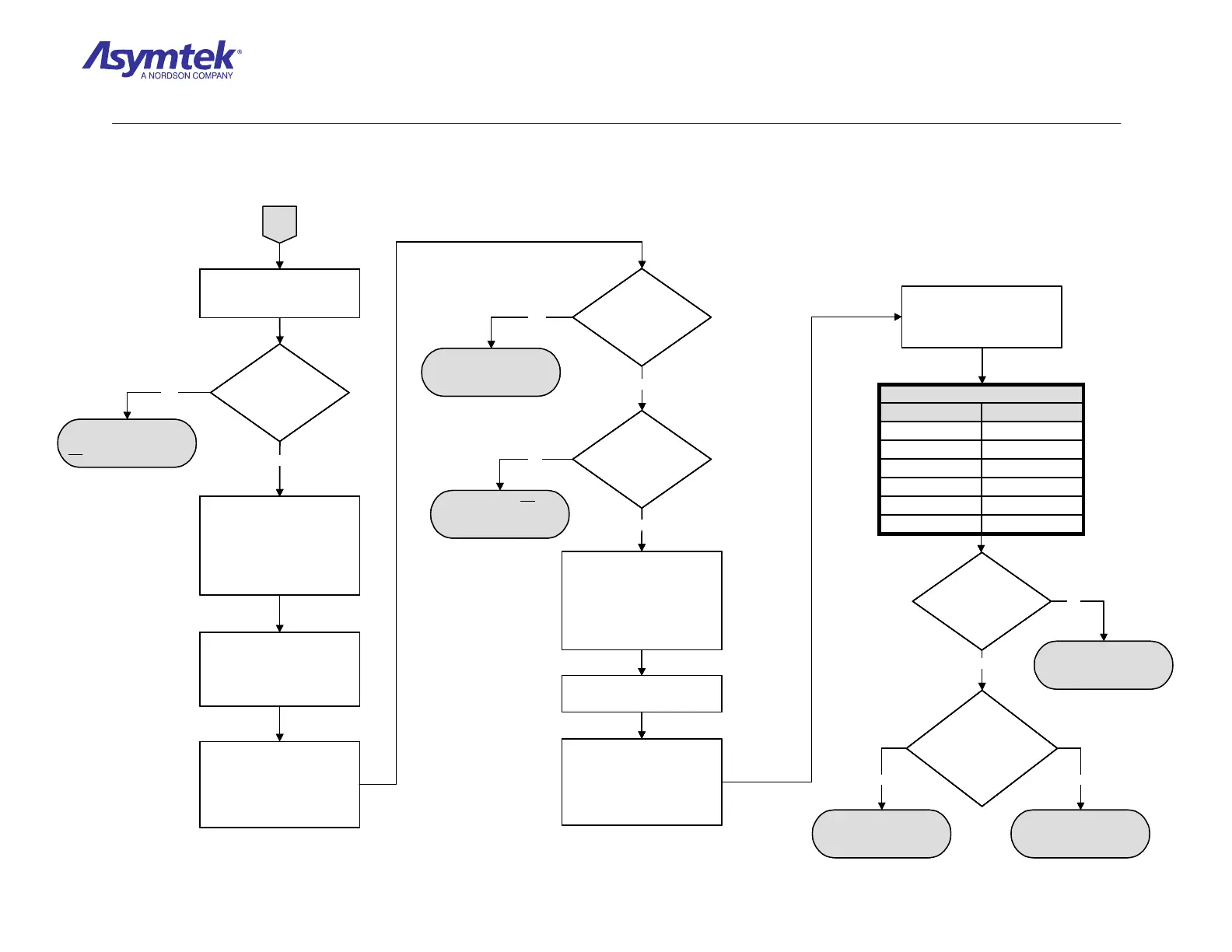

Stop! The Board Sensor is

not

root cause of the fault

Is bit changing

in Conveyor I/O

screen display when

workpiece is passed

beneath it?

Is bit changing

in Conveyor I/O

screen display when

workpiece is passed

beneath it?

In FmNT, observe the

Conveyor I/O screen display

on the Monitor.

A

Exit FmNT, shut down

Windows NT, press black

OFF (0) button on the

Operator’s Console, switch

Main Circuit Breaker to OFF

(0), and disconnect Power

Cable from facility outlet

Exchange the Board Sensor

Connector with another

Board Sensor Connector at

the Conveyor Interconnect

PWA.

Connect the Power Cable to

the facility outlet, switch Main

Circuit Breaker to ON (I)

position, press the green ON

(I) button on the Operator’s

Console, and enter FmNT.

Did the error follow

the exchanged Board

Sensor Connector?

Did the error follow

the exchanged Board

Sensor Connector?

Did the error move

to the other Board

Sensor?

Did the error move

to the other Board

Sensor?

Exit FmNT, shut down

Windows NT, press black

OFF (0) button on the

Operator’s Console, switch

Main Circuit Breaker to OFF

(0), and disconnect Power

Cable from facility outlet

Remove side cover from

Conveyor Controller.

Connect the Power Cable to

the facility outlet, switch Main

Circuit Breaker to ON (I)

position, press the green ON

(I) button on the Operator’s

Console, and enter FmNT.

Measure signal between pin

and ground on the Conveyor

Interface PWA at the

locations specified in Table 1.

U6, Pin 1Sensor Right B

U4, Pin 7Sensor Center B

U4, Pin 3Sensor Left B

U6, Pin 3Sensor Right A

U4, Pin 5Sensor Center A

U4, Pin 1Sensor Left A

Pin LocationSensor

Table 1

U6, Pin 1Sensor Right B

U4, Pin 7Sensor Center B

U4, Pin 3Sensor Left B

U6, Pin 3Sensor Right A

U4, Pin 5Sensor Center A

U4, Pin 1Sensor Left A

Pin LocationSensor

Table 1

When the Board

Sensor is unblocked, is

reading 24 VDC?

When the Board

Sensor is unblocked, is

reading 24 VDC?

When Board

Sensor is blocked,

does Conveyor Controller

toggle from high (24

VDC) to low (approx.

0 VDC)?

When Board

Sensor is blocked,

does Conveyor Controller

toggle from high (24

VDC) to low (approx.

0 VDC)?

Conveyor Controller

(P/N 62-1677-00 for

X1020 or 62-1676-00 for

X1010) has failed.

Go to Conveyor Signals

Cable Verification.

Board Sensor has failed.

Board Sensor is not root

cause of fault. If fault

reoccurs, contact Asymtek

Technical Support

Conveyor Controller

(P/N 62-1677-00 for

X1020 or 62-1676-00 for

X1010) has failed.

Yes

No

Yes

No

Yes

No

Yes

No

Yes No

Diagram Sheet 4-8-4

Board Sensor Fault Isolation Procedure - Board Sensor Verification (Continued)

Loading...

Loading...