Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-146 P/N 196515 (Revision A)

Information Sheet 4-13-1

DP-3000 Troubleshooting

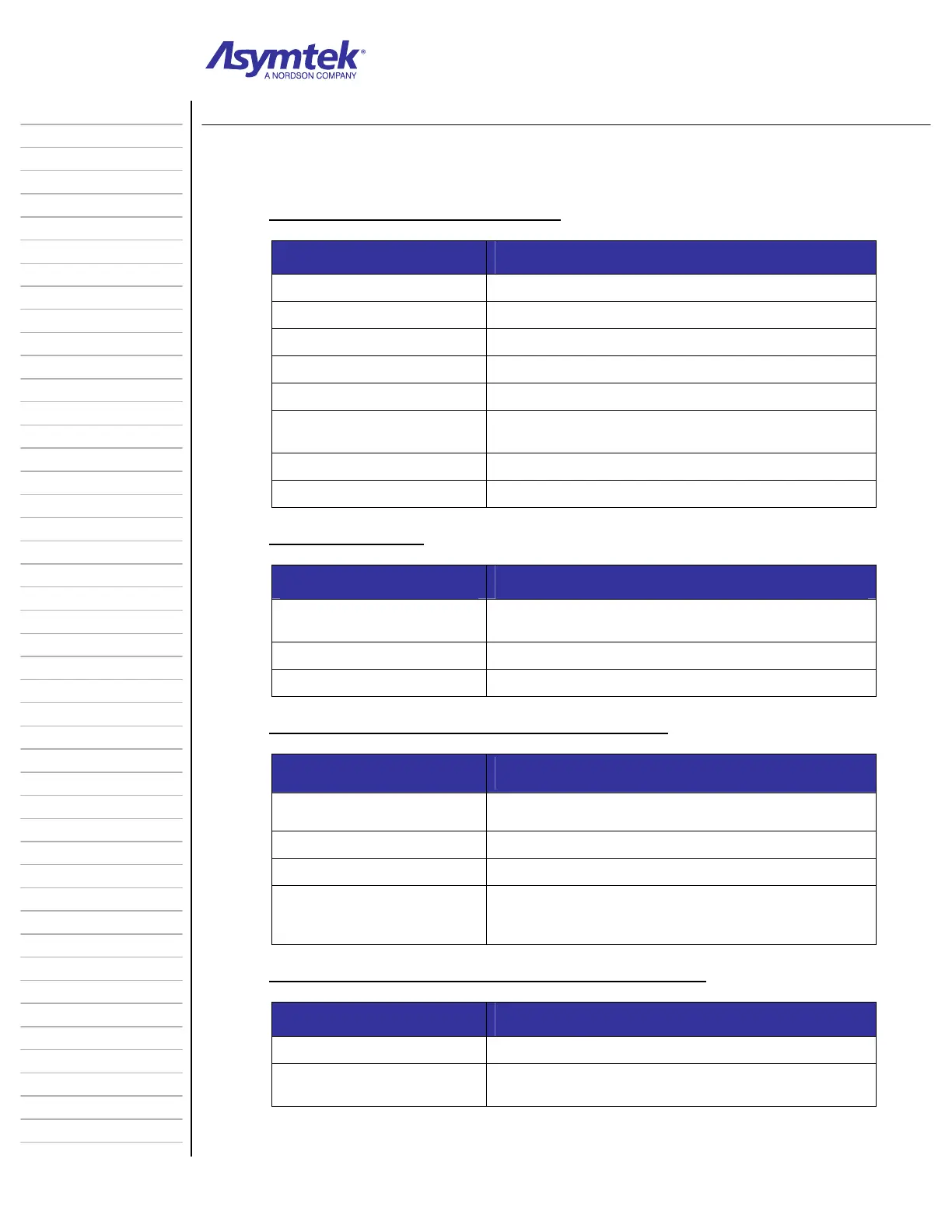

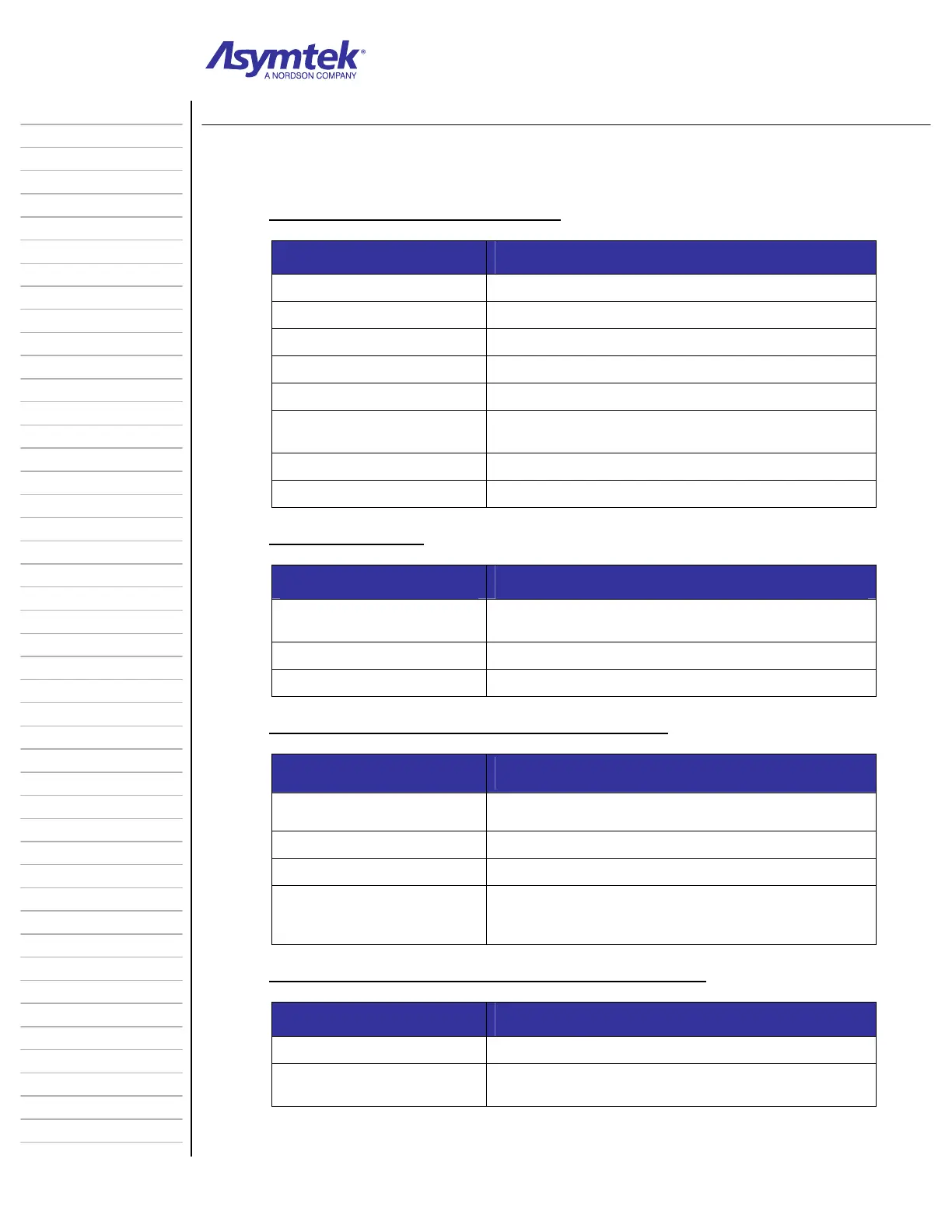

A. Intermittent or No Fluid Dispensing

Possible Cause Recovery

Pump poorly primed Perform a priming sequence.

Clogged dispensing tip

Replace tip.

Plugged pump Clean pump.

Empty fluid reservoir Replace fluid reservoir.

Speed Control set to 0 rpm Increase Valve Speed.

Tip too close to substrate

or touching substrate

Adjust height sensing. Flatten parts or fixture.

Material cured in pump None. Chamber is destroyed.

Feed screw jammed Free feed screw. Refer to Valve Operations Manual.

B. No Power to Motor

Possible Cause Recovery

Loose Interface Cable

connection

Tighten Interface Cable connectors.

Loose CB-036 connection Tighten cable connectors.

Driver circuits failed Check driver fuse on system rear panel.

C. Material Drips Continuously From Dispensing Tip

Possible Cause Recovery

Pump poorly primed Perform a priming sequence.

Needle too small Use a larger gauge needle.

Flow rate is too high Reduce the flow rate.

Thick material causing

pump chamber to over-

pressurize

Use a shorter needle.

D. Fluid Leaking From Prime Port On Side Of Pump Body

Possible Cause Recovery

Seals are worn out Replace seals.

Valve pressure or fluid

pressure set too high

Lower valve pressure (non-encoded models) or fluid

pressure (encoded models).

Loading...

Loading...