Service Manual

683311W

7-3

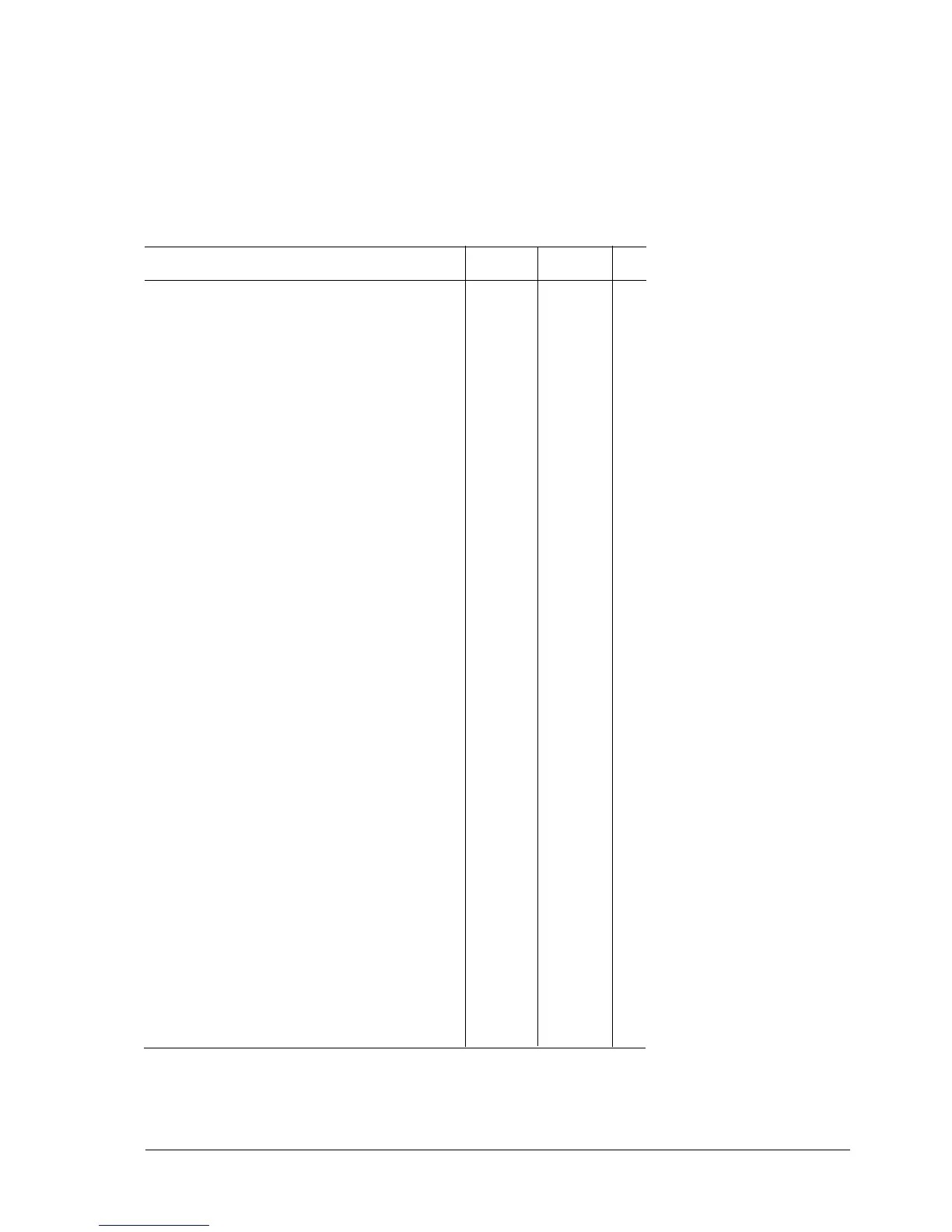

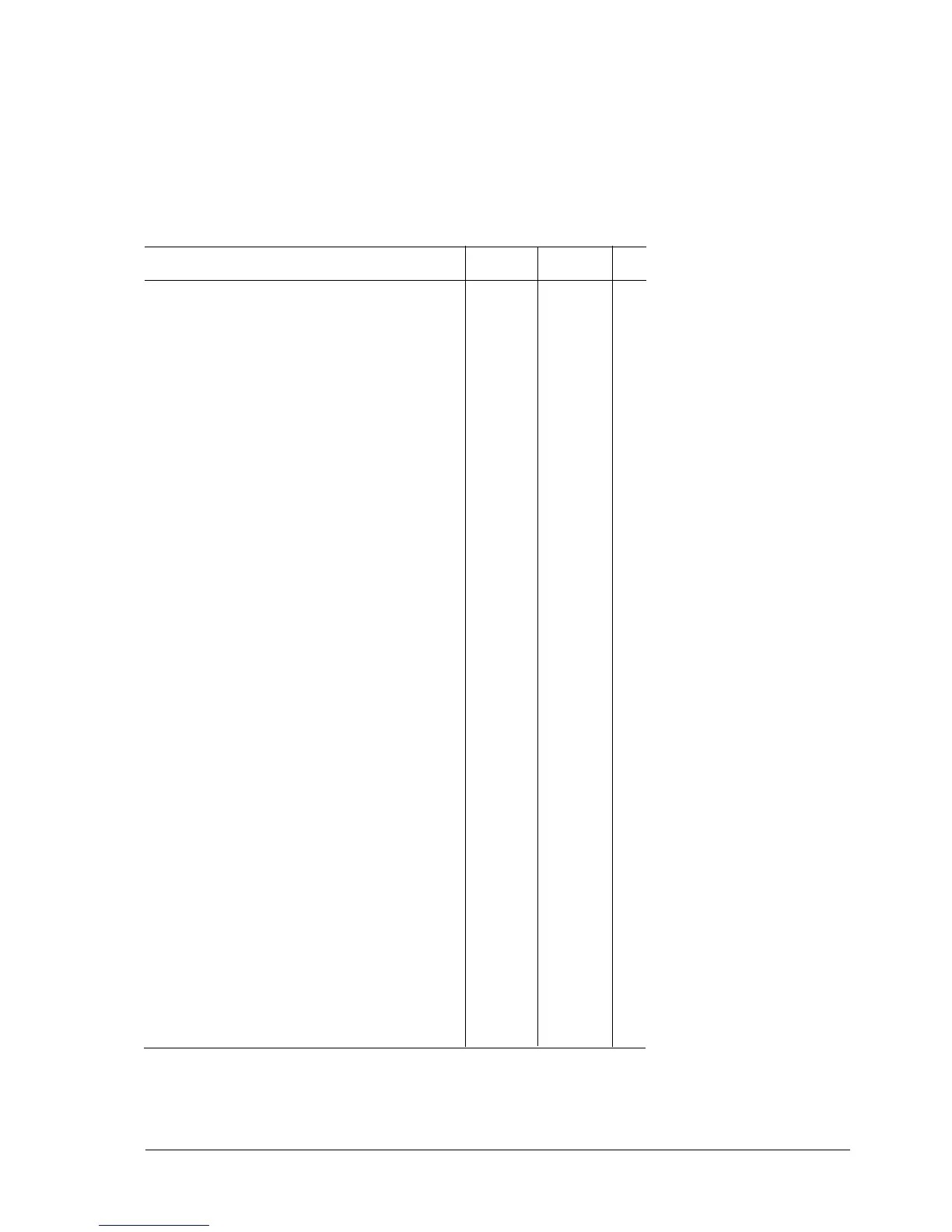

7.3 LUBRICATION

Although lubrication is not foreseen during the machine life, the technician should, during each

service call, check the lubrication using the table below for reference on the parts to be lubricated.

7.3.1 BASIC MACHINE LUBRICATION POINTS

DESCRIPTION CODE GREASE OIL

Print head carriage slide shafts X

Carriage shield guide shaft X

Carriage felt 473150E X

Ribbon feed gear assembly X

Cam in the area in contact with: 473072X X

Reed support pin, 473076T X

Pressure device bridge roller 473074Z X

Bushing hole 473170A X

473171X X

Central pressure device in the shaft contact area 473167T X

Bushings in the shaft contact area 473087P X

473088Y X

Motor gear, 473070H X

gear 473071W X

and cam teeth 473072X X

Assembly gear 473174S X

and pulley toothing 473017Q X

Hooking area leaf spring 473182K X

Ribbon feed pin rotation axis 473147X X

Belt tightener pin with return pulley 473149H X

Alignment rollers shaft 473079E X

Rubber in the damper assembly hole 473059A X

Print crosspiece 473040B X

Left pin and ballast 473049G X

Guide hole center pin X

Left bracket holes and pins

Crosspiece adjustment

Grease: Code 3233350 X MAGNALUBE - E

Oil: Code 757283 C - FOMBLINY 06 oil (perfluorate polyether)

Supplier: Ausimont, Montedison Group

Loading...

Loading...