Handbook

November 2011 / 59-UMC0071 / Issue 01

Mercury iTC

Page 61

FUNCTIONAL DESCRIPTION

Original Instructions

The iTC uses a PID loop to control each heater (see Chapter 12 for information on PID

loops). The control system includes a dead-man’s-handle timer to confirm that the

control loop is operating. If the control loop stalls, the heater output is disabled.

4.2.4 Heater and sensor connections

The heater and sensor are connected via a 9-way D-socket on the rear panel.

Connections to the sensor vary depending on the type of sensor in use (see Table 4-2).

4.2.4.1 Connecting thermocouples

Thermocouples must be connected using the correct wire type to ensure measurement

accuracy.

4.2.5 Communications interfaces

Connectors for the communications interfaces are located on the rear panel of the iTC.

The unit has the following interfaces:

Serial RS232 + ISOBUS (see Section 4.2.5.1)

Serial2 USB (see Section 4.2.5.3)

GPIB (IEEE-488) (optional) (see Chapter 17)

Ethernet 10/100 IEE802.3 (see Section 4.2.5.4)

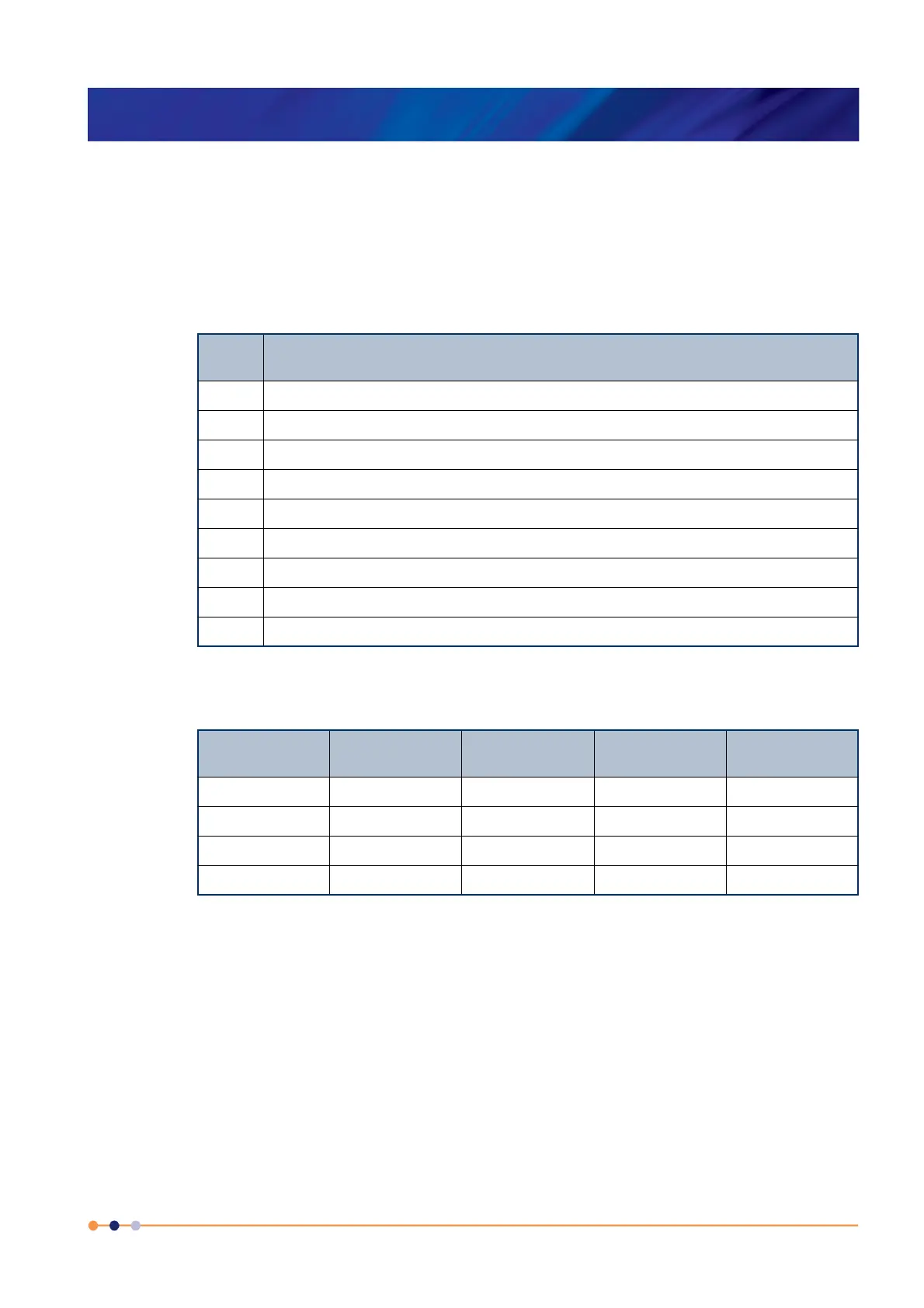

Table 4-1 Channel pin connections

Pin

Number

Connection

1 Sensor input high

2 Sensor input screen.

3 Sensor input low

4 Current source +ve

5 Current source -ve

6 Heater output +ve

7 Heater output -ve

8 Not used

9 Chassis ground.

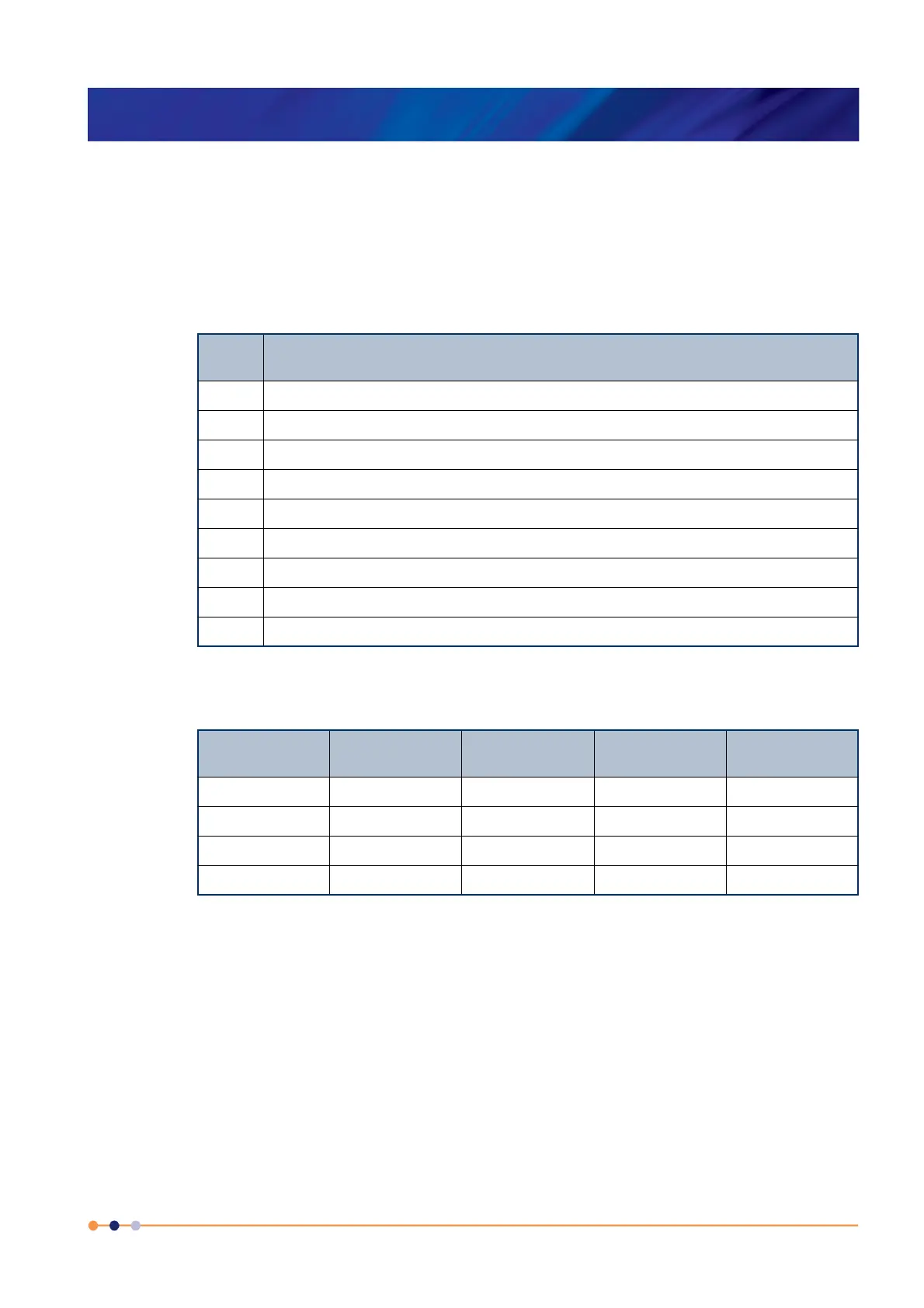

Table 4-2 Sensor connections

Connection Thermocouple Metal Resistor Ge/Carbon

Resistor

Si/Ga As Diode

Input High V+ V+ V- V-

Input Low V- V- V+ V+

Current +ve n/c I+ I+ I+

Current -ve n/c I- I- I-

Loading...

Loading...