Handbook

November 2011 / 59-UMC0071 / Issue 01

Mercury iTC

Page 67

FUNCTIONAL DESCRIPTION

Original Instructions

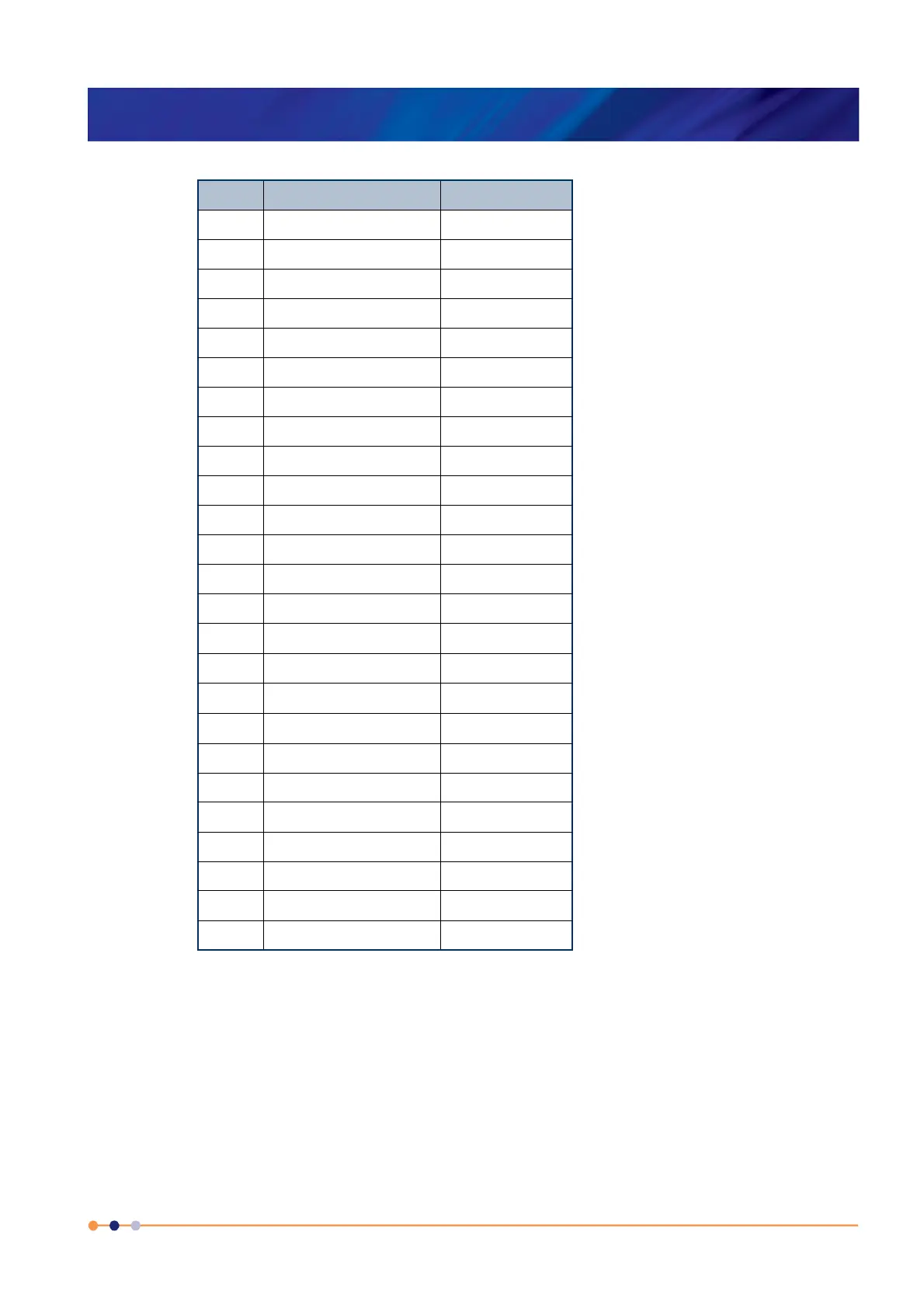

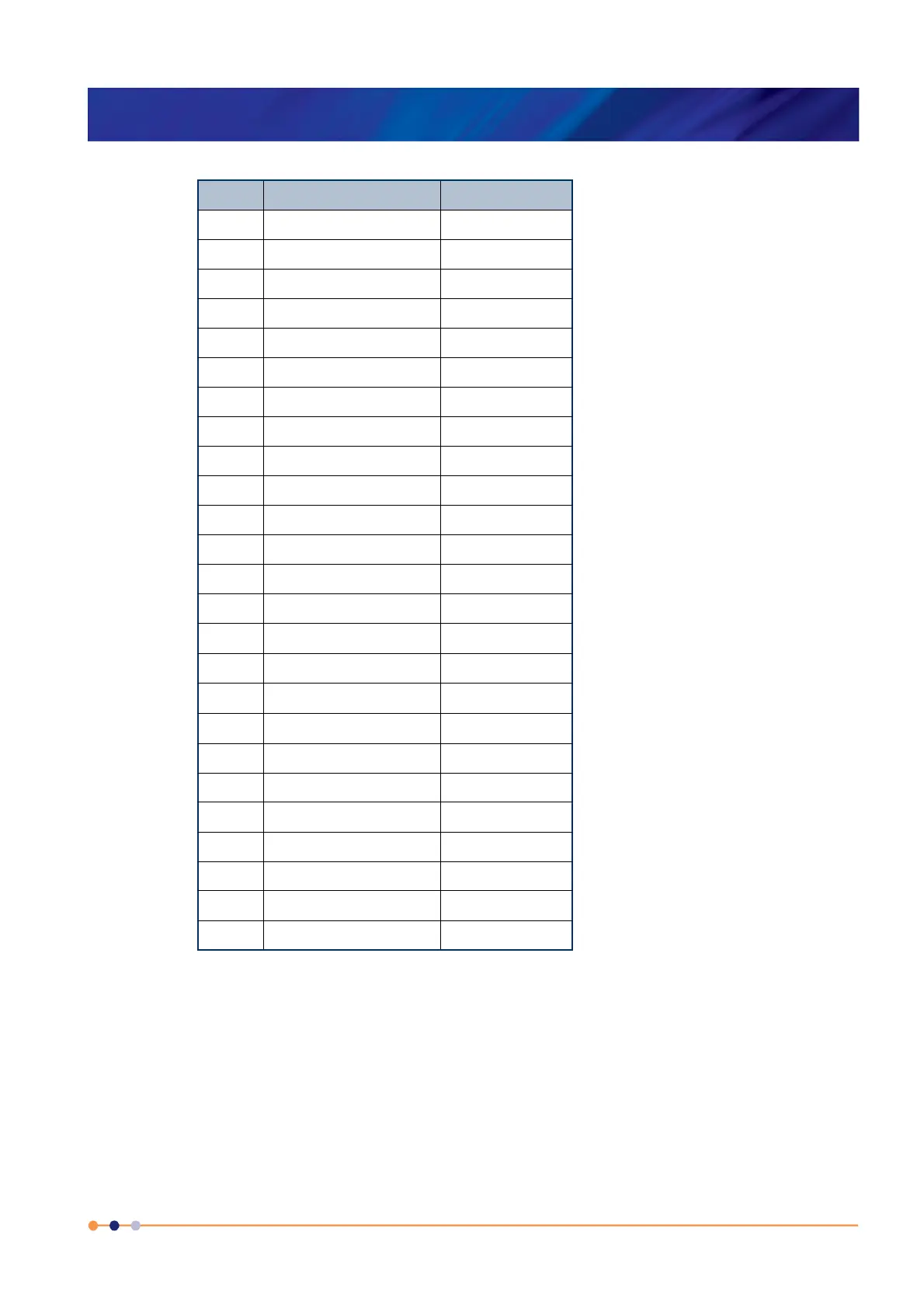

TG 5 AuFe 0.03/Chr 2 to 500K

TG_57 AuFe 0.07/Chr 2 to 500K

TG_57 AuFe 0.07/Chr 2 to 500K

TG_57 AuFe 0.07/Chr 2 to 500K

CN 3 Cernox resistor 1.5 to 300K

TT 5 Copper/Const 20 to 500K

TT 5 Copper/Const 20 to 500K

TT 4 Copper/Const -250 to 400°C

TT 4 Copper/Const -250 to 400°C

TK 10 Chromel/Alumel 0 to 1000°C

TK 10 Chromel/Alumel 0 to 1000°C

TK 13 Chromel/Alumel -200 to 1370°C

TK 13 Chromel/Alumel -200 to 1370°C

CR 11 Ruthenium oxide 0.25 to 10K

RF 52

2

RhFe resistor 1.5 to 500K

RP 1 Platinum resistor -200 to +100°C

RP 5

3

Platinum resistor 20 to 500K

RP 51

4

Platinum resistor 50 to 500K

RL 3 CLTS 2 to 300K

DS 32 Silicon diode (OI) 2 to 300K

DS 31 Silicon diode (LS) 2 to 300K

CC 35 C-glass CR500 2 to 300K

CA 21 100R Allen Bradley 4 to 250K

CA 22 270R Allen Bradley 4 to 250K

CS 01 470R Speer 0.25 to 9.999K

1. The Lin and Null ranges are general purpose ranges that

may be configured for any required span and zero. Both

ranges provide a linear relationship between input and

display. The Lin range is unipolar while the Null range is

bipolar.

2. The iTC includes two curves for 27 Ohm Rhodium/Iron

sensors. Curve A is used for sensors having a resistance of

2 Ohms or greater at 4.2K. Curve B is used for sensors

having a resistance of less than 2 Ohms at 4.2K. Using the

appropriate curve should produce linearisation errors of

less than 1% over the full temperature range. For a more

accurate fit to a specific sensor, order a custom calibration.

3. This is for a pure platinum element.

Table 4-6 Sensor range data

Code Sensor Range

Loading...

Loading...