14

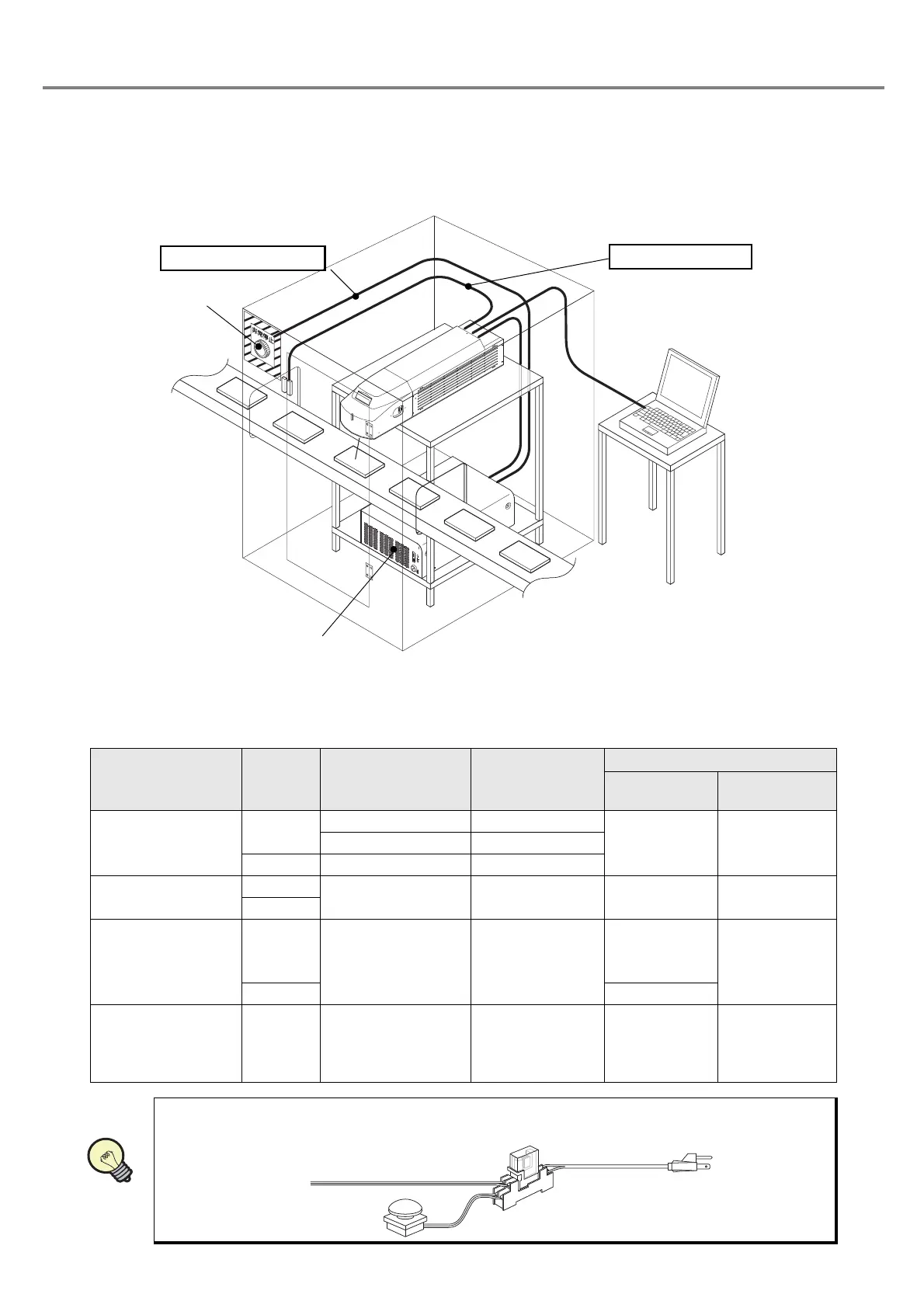

■ Construction Sample of Interlock System

• For operating this product, construct the protective enclosure enclosing the range of the laser radiation for

protecting the exposure caused by the reflection of the laser radiation from the object being marked or the

surrounding objects, and also construct the interlock system at the same time. The following figure shows

the construction sample of the interlock system.

■ Operation at Interlock Input

As shown in the table below, this product outputs error state by canceling the interlock input and also stops the

laser oscillation aiming for safety use of this product.

Status of

Interlock Input

Shutter

Laser Oscillation

(Marking

Operation)

Laser Radiation

Indicator

Laser Marker

Status

Head display

panel

Short-circuit

OPEN

ON Red

Normal

Operation

File No.OFF Blue

CLOSE OFF Blue

Release

OPEN

OFF Blue Alarm Status Error Code

CLOSE

Release

↓

Short-circuit

OPEN

OFF Blue

Ready OFF

↓

after 15 sec.

Ready ON

Error Code

↓

after 15 sec.

File No.

CLOSE Ready OFF

Short-circuit

↓

Release

(Releasing during

marking operation)

OPEN

ON

↓

OFF

Red

↓

Blue

Normal

↓

Alarm Status

File No.

↓

Error Code

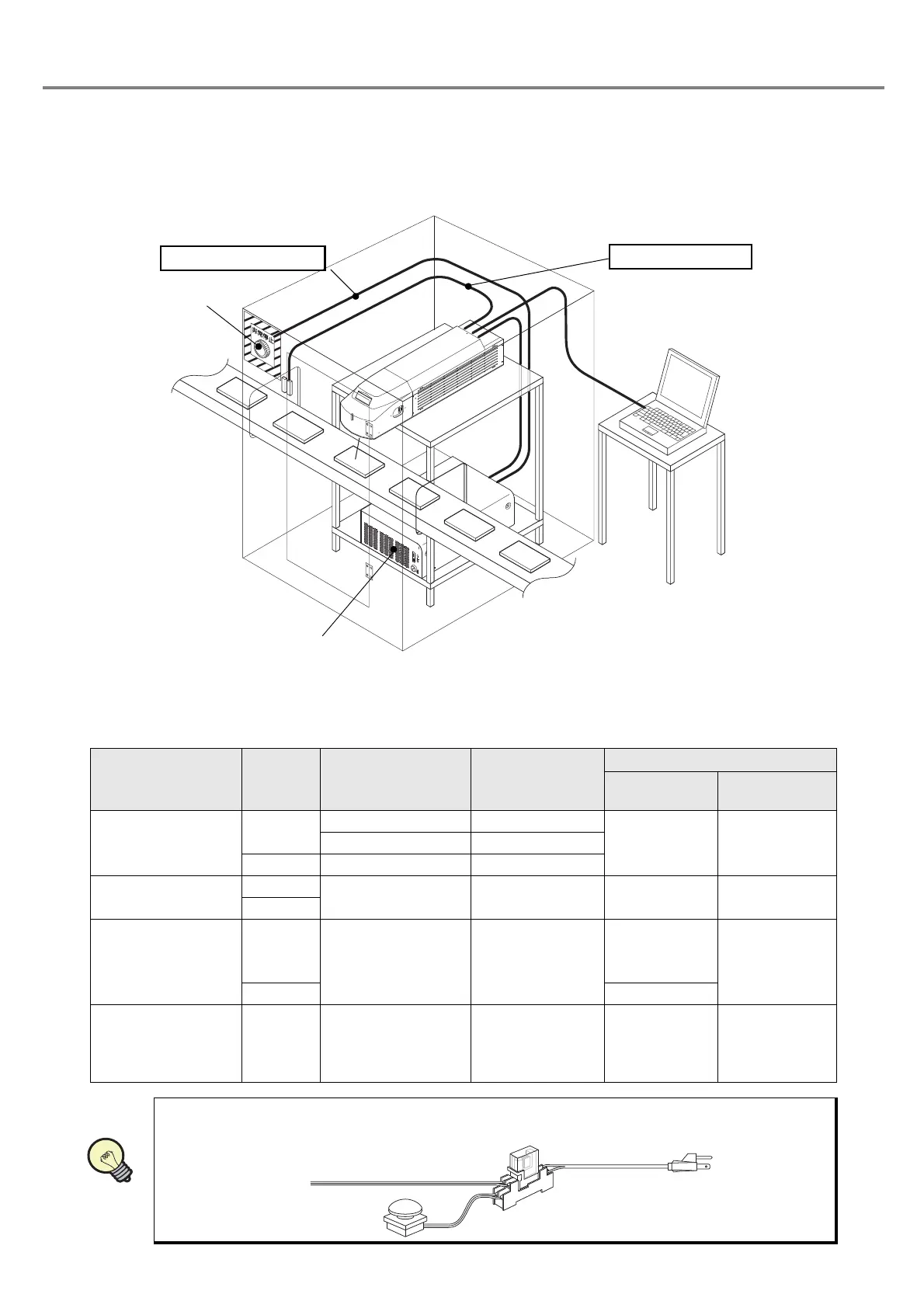

•

When primary AC power supply of the system is performed as a safety measure, process AC

power cable to set the switch as follows.

Power Supply BOX

To Interlock Connector

I/O Connector at Head

To Laser Stop Input

Emergency Stop

Switch

Power Supply BOX

PC

Relay

Emergency Stop Switch

AC Power Cable

Loading...

Loading...