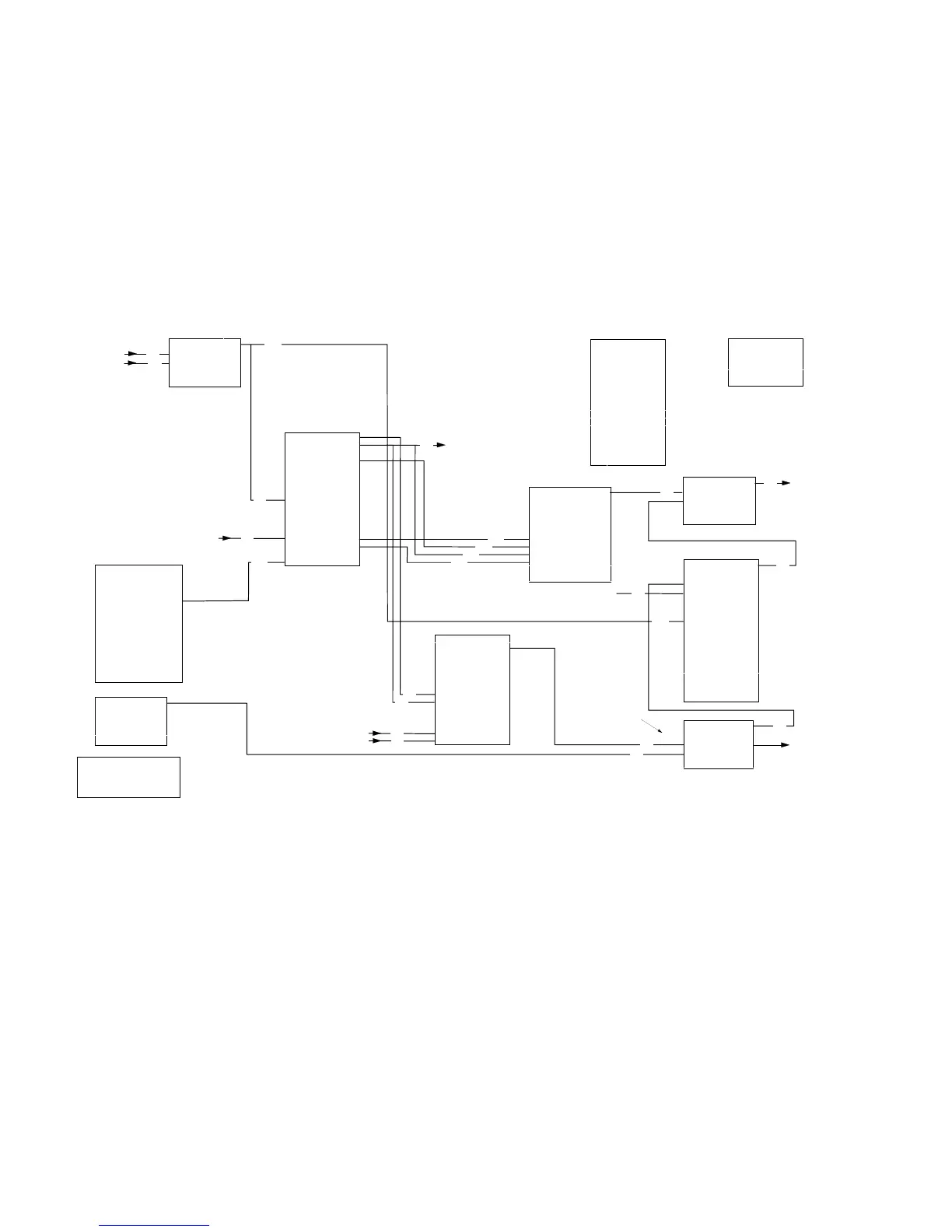

Application Macros 5-10

690+ Series Frequency Inverter

Run DIN1 (previous sheet)

Value Func 1

OUTPUT [133] –

– [130] INPUT A –

– [131] INPUT B –

0.00

0.00

0.00

0.00 – [132] INPUT C –

A+B+C

– [134] TYPE –

Logic Func 2

OUTPUT [188] –FALSE

FALSE – [185] INPUT A –

FALSE – [186] INPUT B –

FALSE – [187] INPUT C –

OR (A,B,C)

– [189] TYPE –

–

–

–

–

Value Func 2

OUTPUT [138] –

[135] INPUT A –

[136] INPUT B –

[137] INPUT C –

SWITCH (A,B)

[139] TYPE –

0.00

50.00

0.00

0.00

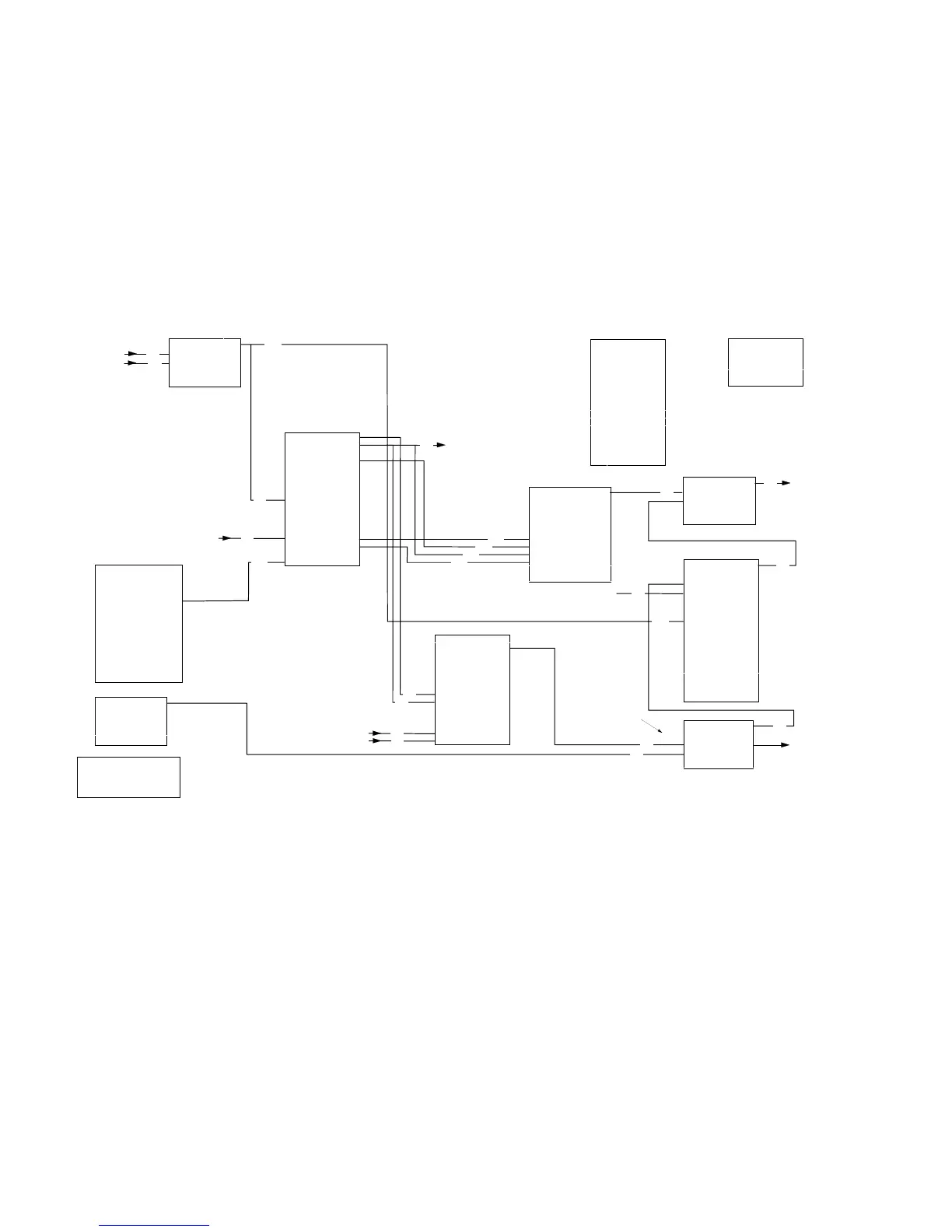

Compensation

– COMPENSATIONS [817] – 0.00 %

– INERTIA COMP [818] – 0.00 %

– SCALED RATE [819] – 0.00 %

– LINE SPEED RATE [820] – 0.00 %

10.00 % – [805] DIAMETER –

10.00 % – [806] MINIMUM DIAMETER –

0.00 % – [807] VARIABLE INERTIA –

0.00 % – [808] FIXED INERTIA –

0.00 % – [809] WIDTH –

FALSE – [810] UNWIND –

0.00 % – [811] LINE SPD DEMAND –

0.00 % – [812] RATE CAL –

FALSE – [813] REVERSE –

0.00 % – [814] DYNAMIC COMP –

0.00 % – [815] STATIC COMP –

0.00 % – [816] MOD REEL SPEED –

10.00 %

10.00 %

Diameter Calc

– CURRENT CORE [834] –

– DIAMETER [835] –

– MOD LINE SPEED [836] – 0.00 %

– MOD REEL SPEED [837] – 0.00 %

FALSE – [821] DIAMETER HOLD –

FALSE – [822] PRESET ENABLE –

FALSE – [823] SELECT CORE 2 –

FALSE – [824] SEL EXT DIAMETER –

FALSE – [825] TENSION ENABLE –

10.00 % – [826] CORE 1 –

10.00 % – [827] CORE 2 –

5.00 s – [828] DIAMETER TC –

0.00 % – [829] EXT DIAMETER –

0.00 % – [830] LINE SPEED –

10.00 % – [831] MINIMUM DIAMETER –

5.00 % – [832] MINIMUM SPEED –

0.00 % – [833] REEL SPEED –

Taper Calc

– TAPERED DEMAND [850] – 0.00 %

– TENSION DEMAND [851] – 0.00 %

FALSE – [838] HYPERBOLIC TAPER –

FALSE – [839] STALL ENABLE –

FALSE – [840] BOOST ENABLE –

FALSE – [841] FIXED BOOST –

FALSE – [842] FIXED STALL TEN –

0.00 % – [843] CURRENT CORE –

10.00 % – [844] DIAMETER –

0.00 % – [845] BOOST –

1.000 s – [846] TENSION RAMP –

0.00 % – [847] STALL TENSION –

0.00 % – [848] TAPER SPT –

0.00 % – [849] TENSION SPT –

Torque Calc

– POS TORQUE LIMIT [790] – 200.00 %

– NEG TORQUE LIMIT [791] – -200.00 %

FALSE – [786] OVER-WIND –

FALSE – [787] TENSION ENABLE –

0.00 % – [788] TENSION DEMAND –

200.00 % – [789] TORQUE LIMIT –

Speed Calc

– SPEED DEMAND [784] – 0.00 %

– UP TO SPD (UTS) [785] – TRUE

FALSE – [774] UNWIND –

FALSE – [775] OVER-WIND –

FALSE – [776] OVER SPD ENABLE –

5.00 % – [777] UTS THRESHOLD –

0.00 % – [778] LINE SPEED –

0.00 % – [779] MOD REEL SPEED –

10.00 % – [780] DIAMETER –

10.00 % – [781] MINIMUM DIAMETER –

0.00 % – [782] OVER SPEED –

0.00 % – [783] SPEED TRIM –

PID

PID OUTPUT [320] – 0.00 %

PID ERROR [766] – 0.00 %

0.00 % – [310] SETPOINT –

0.00% – [764] FEEDBACK –

FALSE – [763] SETPOINT NEGATE –

FALSE – [765] FEEDBACK NEGATE –

FALSE – [311] ENABLE –

FALSE – [312] INTEGRAL DEFEAT –

1.0 – [313] P GAIN –

1.00 s – [314] I TIME CONST –

0.000 s – [315] D TIME CONST –

0.100 s – [316] FILTER TC –

20.00 % – [317] OUTPUT POS LIMIT –

-20.00 % – [318] OUTPUT NEG LIMIT –

1.0000 – [319] OUTPUT SCALING –

Switched On (previous sheet)

Logic Func 1

OUTPUT [183] – FALSE

FALSE – [180] INPUT A –

FALSE – [181] INPUT B –

TRUE – [182] INPUT C –

AND (A,B,C) – [184] TYPE –

(5)

(11)

(27)

(21)

Diameter ANOUT2 (previous sheet)

(25)

(27)

(26)

(28)

(19)

(32)

(33)

(31)

(30)

(29)

(23)

(24)

(27)

Line Speed ANIN1 (previous sheet)

(1)

Taper Spt ANIN4 (previous sheet)

(16)

Tension Spt ANIN3 (previous sheet)

(15)

Feedback ANIN2 (previous sheet)

(3)

Speed Demand (previous sheet)(14)

Input A is used to provide

a boolean for the operator

menu (LOAD CELL FBK).

Tension Dancer Spt. ANOUT3

Loading...

Loading...